Keyboard ALT + g to toggle grid overlay

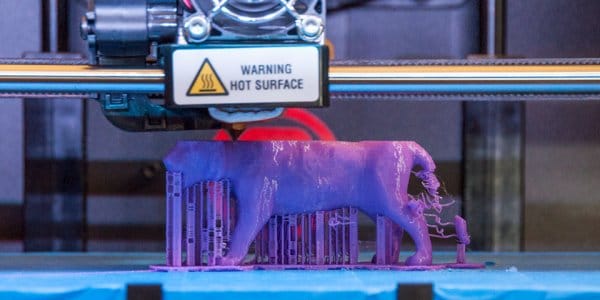

What is additive manufacturing?

Additive manufacturing, also known as 3D printing, is a process used to create a physical (or 3D) object by layering physical materials one by one based on a digital model. Unlike subtractive manufacturing that creates its final product by cutting away from a block of material, additive manufacture adds parts to form its final product.

How is additive manufacturing used?

Additive manufacturing is used with 3D modeling software and machine equipment that is able to read and layer CAD files into a 3D object. Additive Manufacturing adds to current production technology, enabling users to create highly customized objects.

Current additive manufactured products include aircrafts (US site), dental designs, medical implants, and automobiles.

Custom Tailored Products

Image Courtesy of Under Armour

Co-Creation with Customers

Image Courtesy of Under Armour

Lightweight Components Using Lattice Structures

Image Courtesy of Under Armour

Product Design & Manufacturing Collection

Make anything with our best Inventor, with integrated tools for advanced simulation and 5-axis CAM. Collection also includes access to Fusion 360, helping you get on the path to the future of making things with our cloud-based product innovation platform.

Trends & resources in additive manufacturing

Read up on trends and future materials used in additive manufacturing.

-

Lower-cost and safer processes are innovating the additive manufacturing space and offering different material properties through resolution, surface quality and design freedom.

-

Read tips on whether to adopt additive manufacturing systems in-house or outsourced as an industrial manufacturer.

-

New materials developed and used for additive manufacturing will shape the future and growth of additive manufacturing.

-

Autodesk has established an Additive Manufacturing Alliance that brings together leading industrial companies and their insights on solving design, simulation, and manufacturing processes.

-

Five trends to observe in 2017 for Industrial Additive Manufacturing.