Keyboard ALT + g to toggle grid overlay

What is CNC programming?

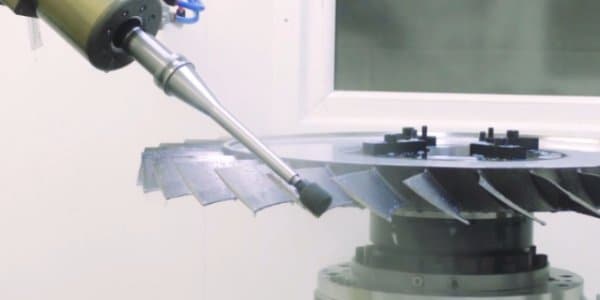

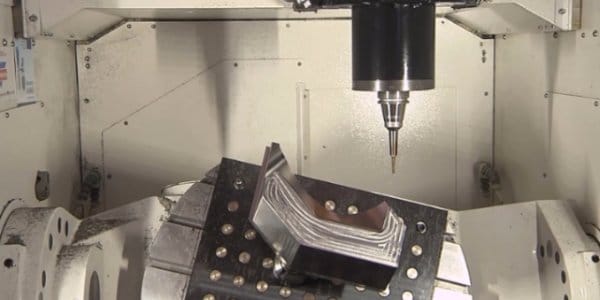

CNC programming (Computer Numerical Control Programming) is utilized by manufacturers to create program instructions for computers to control a machine tool. CNC is highly involved in the manufacturing process and improves automation as well as flexibility.

Types of CNC machines

CNC programmers write instructions for CNC machines, where a computer is connected to the mill, along with electrical drives and sensors for a complete system. This computer controls the movement of the machine axis.

-

3-axis machining

The most common CNC machines produced commercially. Used for simple prismatic parts—to complex molds, medical or aerospace parts.

Get a collection for a better value on CNC software

The Product Design & Manufacturing Collection offers our best Inventor and other CNC supporting software including HSM and Fusion 360. Get the best value by subscribing to our collection with over a dozen products.

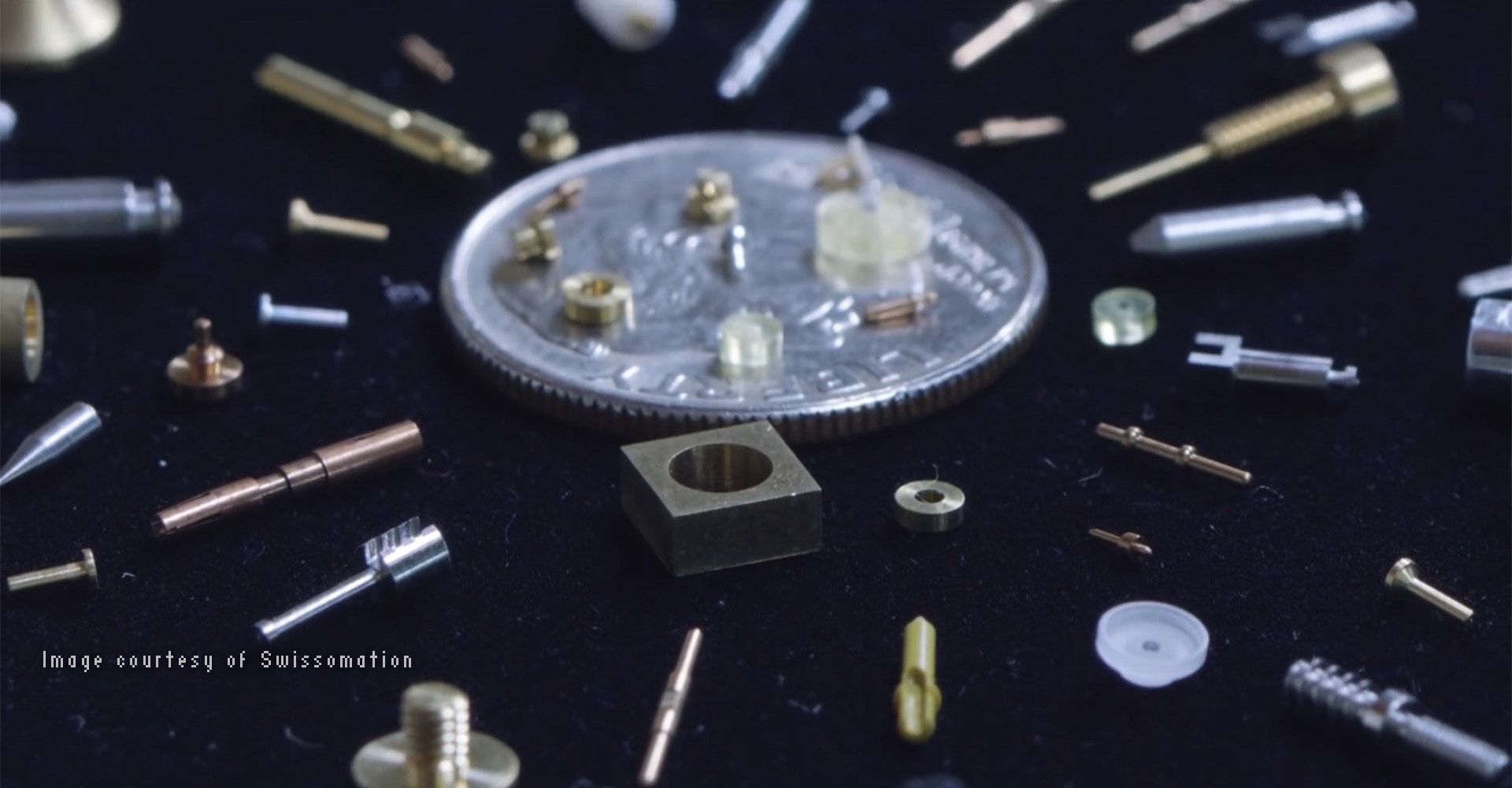

The real life of a precision machinist

Get the real story on how precision machinist Christian Welch and his company, Swissomation, turn out the tiniest parts for mobile phones and more.

Find CNC programming resources

Get started with CNC programming with these tutorials, guides, tips and tricks.

-

Fundamentals of CNC machining (US site)

Bridge the gap between your technical education and what you need to know to begin using CNC machine tools.

-

Getting started with g code (US site)

Review g code basics to efficiently understand and write programs that product high quality products.

-

Eliminating manual programming (US site)

The market place for job-shops is rapidly changing, with competition coming from all directions as everyone tightens their machining operations.

-

Watch an Autodesk presentation on the overview of CNC machines, process, and CNC programming.

-

Machines & tools (US site)

Explore the equipment in our workshop, including machine models and manufacturers, online guides, and skill-based tutorials.

-

CAM programming (US site)

Get tips and techniques to meet your CAM programming goals with greater consistency and efficiency.