& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

& Entertainment

Entertainment content creation tools, including 3ds Max and Maya

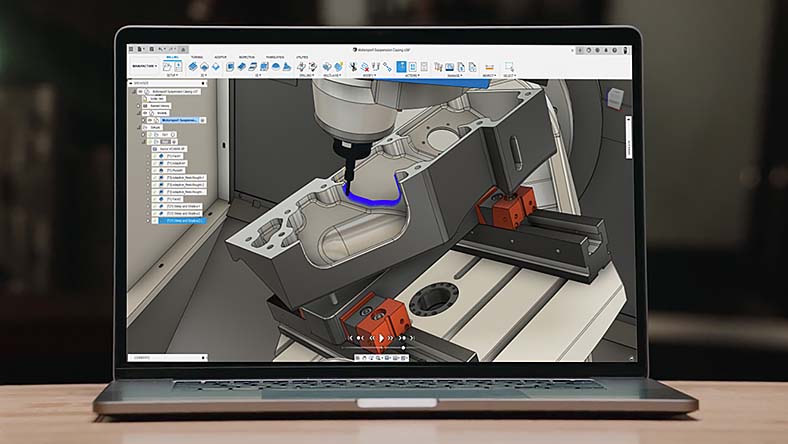

Design beautifully and manufacture efficiently (video: 1:49 min)

Incorporating DFM principles (US Site) into the design process reduces errors, production time and costs. Autodesk Fusion allows engineers to consider manufacturing processes, materials and constraints during the design phase to ensure that the final product can be produced efficiently, cost-effectively and with high quality.

Utilise product design insights, simulation and visualisation tools to minimise rework and troubleshoot product defects early in the design process.

Involve entire teams, individual stakeholders and project vendors when you need to get meaningful feedback on design decisions.

Apply key DFM insights to help reduce material waste, consolidate the number of assembly parts and get production cost estimates.

– Tyler Berryman, Product Design Engineer, Brash Inc.

Seamlessly collaborate with cloud-based data ensuring teams work on the same data. Web browser access grants entry for extended teams and captures design conversations.

Move seamlessly between design and manufacturing workspaces to optimise designs for ease of manufacturing and improve the utilisation of resources.

Autodesk Fusion's simulation environment tests your design under real-world conditions prior to production, minimising the risk of manufacturing failures or design flaws.

Our parametric design capabilities allow for swift, efficient design changes, with an automatic design history update that accommodates manufacturing needs.

Leverage AI to generate various design solutions based on set parameters, choosing the one that’s most cost-effective and easy to manufacture.

Quickly design circuits, visualise your electronic product’s 3D model aspects, and test how the PCB fits within the design assembly (US Site) with ECAD and MCAD integration.

Track different versions and manage all design data in one place. Maintaining design integrity and avoiding confusion during manufacturing.

Optimise material utilisation and simplify the design of a products to improve ease of manufacturing and efficiency of assembly.

Is your organisation considering a move towards more sustainable outcomes? Or perhaps you want to persuade them to do so? This e-book explores various aspects of such an undertaking and examines a wide range of approaches.

1-year subscription: most popular, 1-year access to advanced CAD, CAM, CAE, PCB, data management and collaboration tools with Autodesk Fusion.

1-year subscription: Optimise part design and performance with unlimited cloud solves for generative design, FEA, electronic cooling, injection moulding and more. Requires a Fusion subscription.

Connect with a representative to discuss Autodesk Fusion and find the solution that best fits your company’s product development needs.

Extensions allow you to unlock advanced design and manufacturing technologies in Autodesk Fusion.

Want to try Autodesk Fusion? Download a free 30-day trial

Design for manufacturing (US Site), also referred to as design for manufacturability or DFM, is the process of incorporating restrictions that may be present from intended manufacturing methods into the product/part models during the initial design stages. This helps reduce the need for rework when a product is ready to be manufactured.

An example of applying DFM is when designing a part of which the intent is to manufacture using injection moulding. Design restrictions such as undercuts, parting lines and mould cavity filling need to be considered prior to a mould being built. If these are not addressed prior to mould building, the potential is high for issues like parts stuck in the mould cavity, poor part quality and very expensive tooling.

Autodesk Fusion and its extensions offer integrated CAD/CAM/CAE, parametric modelling, design simulation, generative design and toolpath generation, making it an efficient tool for DFM (US Site). Using one or a combination of its features allows engineers to design parts smartly, reducing post-process rework that can result in longer time to market and more money spent.

Autodesk Fusion can generate toolpaths for different manufacturing processes and create machine programs for CNC machines, ensuring a smooth transition from design to manufacturing. The Autodesk Fusion Machining Extension adds additional tooling methods for more advanced machines.

Generative design uses AI to create various design solutions based on set parameters, helping to choose a cost-effective and manufacturable design. When looking to optimise your part for manufacturability, generative design with Autodesk Fusion can include your manufacturing method of choice into its outcomes. As a result, it will produce outcomes that account for manufacturing method-specific restrictions in the CAD geometry, allowing potential for a quicker design-to-production workflow for the user.