Keyboard ALT + g to toggle grid overlay

What is 3D mechanical engineering and design software?

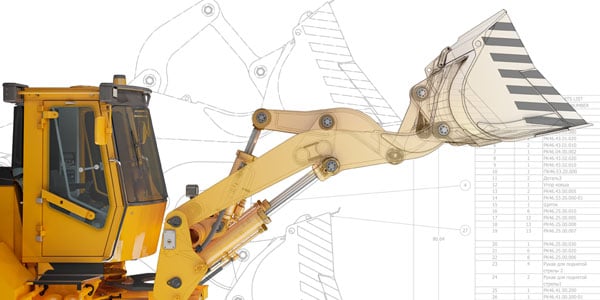

Mechanical engineering and design software helps engineers and designers visualise, analyse and communicate design intent before building a physical prototype. Mechanical engineering software is employed across an array of disciplines, from manufacturing (US site) and architecture (US site) to sustainability. It is used to design everything from cars to prosthetics to headphones.

Types of mechanical engineering and design software

Computer-aided design (CAD) is one of the most ubiquitous software design tools. The models generated by CAD software are often used as inputs to other mechanical engineering and design tools.

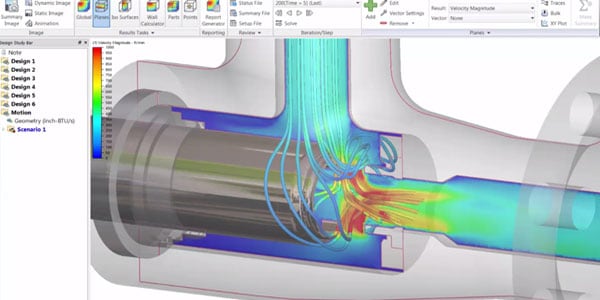

Computer-aided engineering (CAE) is a broad term for software used in aiding engineering analysis. CAE software can perform complex tasks such as finite element analysis (FEA) and computational fluid dynamics (CFD), among others.

Computer-aided manufacturing (CAM) refers to the use of software to help automate the manufacturing process. CAM is typically used after a design has been developed with CAD software and is validated using CAE software before manufacturing.

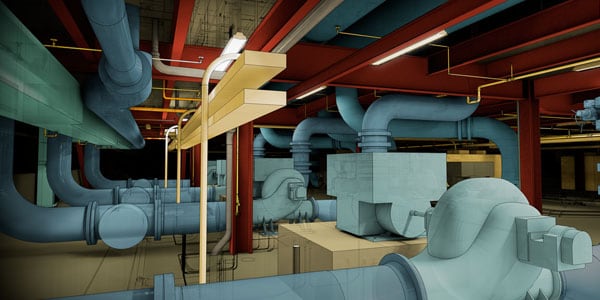

HVAC design software is used to design indoor spaces that meet temperature and air quality requirements. It is often used in the design of large office and industrial buildings.

Product data management (PDM) software helps engineers with document management and revision control.

Turning concepts into reality

Each product starts as a concept, which can take the form of sketches, specifications or constraints that dictate design requirements. A product designer, or usually a team of product designers and engineers, then takes the concept and, using mechanical engineering software, turns the concept into a comprehensive product design. The final design must be manufacturable, that is, be able to meet manufacturing requirements, such as the ability to withstand specified stresses and strains while minimising the final product's weight. This design phase can take several iterations and refining. It can also include a design simulation phase, using software that tests and validates the product design before the final step of manufacturing.

Free software for students & educators

Use the same 3D mechanical engineering software as the top engineers and designers from around the world.

Free software for non-profit organisations

Autodesk supports nonprofit organisations and entrepreneurs using design for positive impact.

Featured 3D mechanical engineering software

-

Fusion 360 (US site)

Fusion 360 combines industrial and mechanical design with collaboration in an easy-to-use, affordable 3D CAD tool.Free trial (US site)

Buy now -

Inventor Professional

Make great products with professional-grade 3D mechanical, documentation and product simulation tools. -

AutoCAD

Choose an AutoCAD software tailored to mechanical engineers, including AutoCAD Mechanical and AutoCAD MEP. -

Autodesk CAM (US site)

Try an integrated CAM solution that works in any CAM programming environment.Access free trials (US site)

-

Autodesk Simulation (US site)

Validate products to better understand the implications of design choices before manufacturing.View Simulation products (US site)

-

Fusion Lifecycle

Next generation cloud-based product lifecycle management. -

Tinkercad

Tinkercad is a free web-based 3D design tool for hobbyists, teachers and students of all ages.

Learn more about mechanical engineering and design

Mechanical engineering resource centre (US site)

Access an expanding repository of mechanical engineering resources to inspire new ideas, deepen your skillset and gain insight into trends in your industry.

Designing safer headphones

A designer shares his design process and the tools that helped him to get there.

Making the world greener, one bus at a time

Vantage Power was able to prototype its design in a very short time, without investing a lot of money and resources for new software.

Bringing clean water to the masses

AguaClara, a Autodesk Cleantech Partner, invented a tool to filter water using only the sun and gravity.

8 tips for using Inventor

Quick tips to make you a more productive designer.