Keyboard ALT + g to toggle grid overlay

What is 3D printing?

3D printing, also known as additive manufacturing, is a process by which physical objects are created by depositing materials in layers based on a digital model. All 3D printing processes require software, hardware and materials to work together.

3D printing technology can be used to create everything from prototypes and simple parts to highly technical final products such as aeroplane parts (US site), eco-friendly buildings, life-saving medical implants and even artificial organs using layers of human cells.

Common methods of 3D printing

Advances are quickly being made to make 3D printing technology reliable for mass manufacturing production-gradient parts and scientists and inventors are finding new ways to apply 3D printing technology every day.

Stereolithography (SLA)

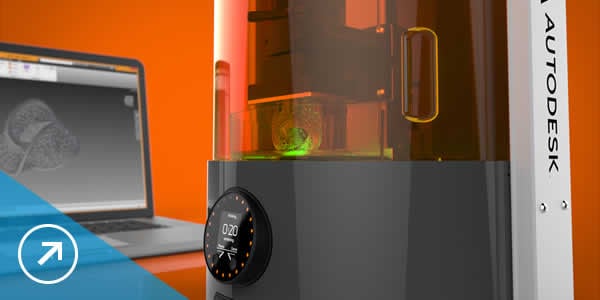

This method of 3D printing uses UV light to cure or harden resins, layer by layer. Example 3D printers include Autodesk Ember and Formlabs Form 1.

Featured 3D printer

Introducing Ember, the first open source, production quality 3D printer. Ember uses high resolution digital light processing SLA technology. Print detailed parts with an accuracy of 25 microns for a smooth surface finish. As part of an open 3d printing platform, Ember can work with a variety of resins.

Featured 3D printer

Ember uses high resolution digital light processing SLA technology. As part of an open 3d printing platform, Ember can work with a variety of resins.

Additive manufacturing today

Capitalise on improvements in additive manufacturing to create better products faster - and stay ahead of the competition.

3D printing for developers

Join our open Spark platform to get access to 3D printing APIs, SDKs and sample applications.

Free for students and teachers

We offer free Autodesk software to students and educators. Get free software for your design and 3D printing projects.

Featured 3D printing portfolio

-

Fusion 360 (US site)

Connect your entire product development process in a single cloud-based platform. Send your designs directly from Fusion 360 to your 3D printer or a 3D printing service provider.

Try free for 30 days (US site) -

Within (US site)

Within generative design software solutions help engineers and orthopedic implant specialists produce lightweight, latticed designs for additive manufacturing.

Learn more about Within (US site) -

Maya

Create 3D animations for video games, films and television. Print 3D models for stop motion animation, or print props and parts for scenes that combine live action and CGI elements.

Try free for 30 days -

Netfabb

Netfabb enables a complete industrial additive manufacturing workflow, from content to machine, making it quick and easy to prepare your models for 3D printing.

Learn more about Netfabb -

Tinkercad

Tinkercad is a free web-based 3D design tool for hobbyists, teachers and students of all ages. Make home decor, jewellery, toys, Minecraft models and more.

Learn more about Tinkercad

See how people are using 3D printing

Making the airliner of the future (US site)

A group of imaginative engineers design their vision for the future of air travel with advanced technologies like generative design (US site) and 3D printing.

How do 3D printers work?

Learn about the four main 3D printing technologies: fused deposition modelling, stereolithography, direct light processing and selective laser sintering.

Printing a safer earbud for music lovers

A pioneer of the first in-ear monitors for professional musicians, Asius Technologies used 3D printing to create an earbud that acts more like the human eardrum.

Design, create and 3D print your own toys

Make your own toys from start to finish with Mattel's ThingMaker 3D printing ecosystem.

3D printing in filmmaking

Why Hollywood loves 3D printing.

Designing jewellery with Fusion 360 and Ember

See how a pendant went from a CAD model to a beautiful piece, cast in sterling silver.

Making 3D printing materials better for the environment

Student researchers at the University of California, Berkeley, search for safer, eco-friendly 3D printing resins.

Read more about 3D printing

Did you know NASA took the first zero-gravity 3D printer into space? Learn more about 3D printing on Redshift.