Keyboard ALT + g to toggle grid overlay

3D printing

Learn how leading manufacturers are making the most of 3D printing to create previously impossible designs and redefine their production abilities.

What is 3D printing?

3D printing, also called additive manufacturing (US site), is a family of processes that produces objects by adding material in layers that correspond to successive cross-sections of a 3D model. Plastics and metal alloys are the most commonly used materials for 3D printing, but it can work on nearly anything—from concrete (US site)to living tissue.

What's 3D printing used for?

Efficiently make one-off parts and create highly complex geometries that are only possible with 3D printing.

Prototyping

3D printing has long been used to quickly create prototypes for visual aids, assembly mockups and presentation models.

Learn more (US site)

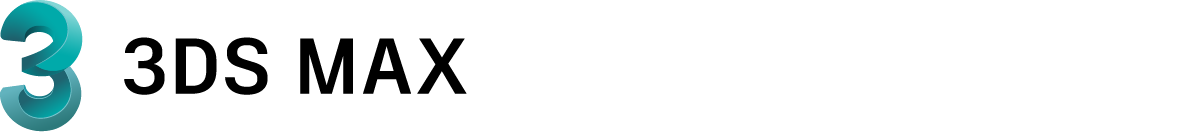

Lightweight parts

Fuel efficiency and emissions reductions are driving the need for lightweight parts via 3D printing in aerospace and automotive applications.

Learn more (US site)

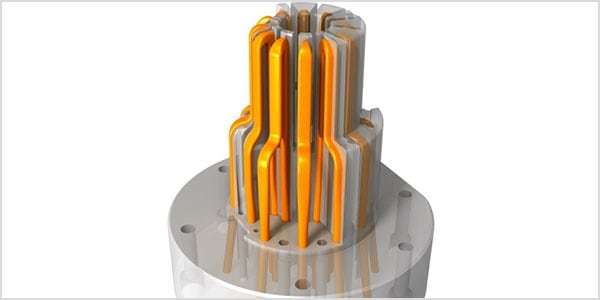

Functionally enhanced products

3D printing removes many of the constraints imposed by traditional manufacturing processes that prevent engineers from truly designing for optimal performance.

Learn more (US site)

Custom medical implants

To achieve osseointegration, manufacturers are using 3D printing to precisely control surface porosity to better mimic real bone structure.

Learn more (US site)

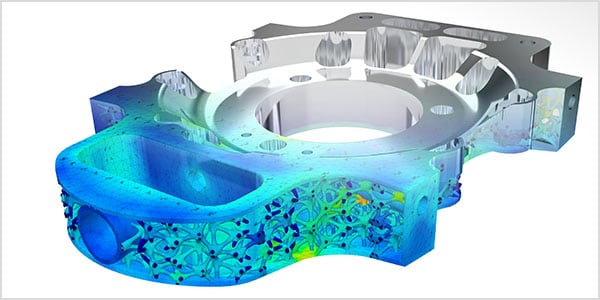

Tooling, jigs and features

3D printed composite tooling and machining fixtures are often cheaper and faster to produce and conformally cooled inserts for injection moulds can dramatically reduce cycle times.

Learn more (US site)

Metal casting patterns

Combining 3D printing with metal casting bridges the gap between generatively designed parts and proven manufacturing approaches for large metal objects.

Learn more (US site)

Who uses 3D printing software?

Airbus bionic partition

Aircraft manufacturer trims the weight of its A320 plane, helping to reduce the carbon footprint of air travel.

See what our customers are doing

Stanley Black & Decker

Using generative design and 3D printing, Stanley Black & Decker's Infrastructure Innovation Centre is exploring new approaches to creating high-performance industrial tools.

Norvax

Novax precisely controls porosity to create bone implants that are “much closer to the real thing.”

Featured 3D printing software

Product Design & Manufacturing Collection

Make anything with our best Inventor, with integrated tools for advanced simulation and 5-axis CAM. Collection also includes access to Fusion 360, helping you to get on the path to the future of making things with our cloud-based product innovation platform.

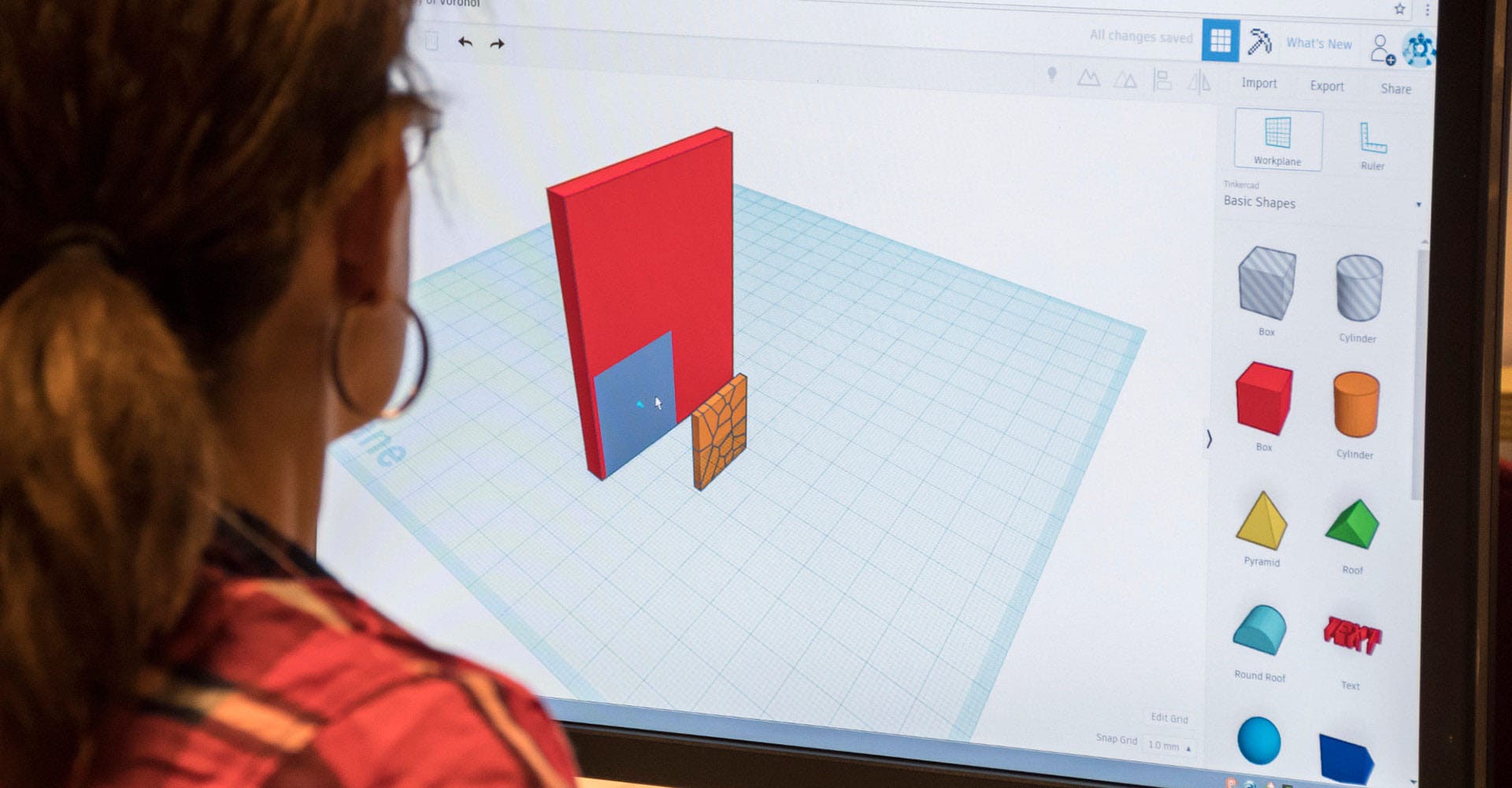

Free 3D printing software: Tinkercad

Tinkercad is a free and simple 3D design and 3D printing app for everyone.

3D printing resources

-

Additive manufacturing resource centre (US site)

Access a variety of resources designed to help you to identify how you can add value to your products with additive manufacturing.

-

Redshift (US site)

Redshift is an Autodesk publication dedicated to telling stories about the future of making things, with an emphasis on novel applications for 3D printing.

-

Stay current with the latest in 3D printing trends and Netfabb software updates.

FOLLOW AUTODESK

Support & Learning

- Manage your Autodesk Account (US site)

- Product support

- Software download, installation, registration & licensing

- Updates & service packs

- System requirements

- Help forums

- Free Software for Students (US site)

- Autodesk University (US site)

- Students & educators (US site)

- Training & certification (US site)

- Events & training (.au)

- Classes on demand

Autodesk

Autodesk is a leader in 3D design, engineering and entertainment software.

- About us (US site)

- Careers (US site)

- Contact us

- Investor relations

- Trust centre (US site)

- Newsroom

- Suppliers (US site)

- Affiliate program

Privacy/Cookies (Updated) | Legal Notices & Trademarks | Report Non-compliance | Site map | © 2015 Autodesk Inc. All rights reserved