Keyboard ALT + g to toggle grid overlay

Creating a beautiful, functional, sustainable garden setting with AutoCAD

More than 250 million people around the world use Pinterest to dream about, plan and prepare for things they want to do in life. The company wanted to extend the interior lobby of its San Francisco headquarters to the outdoors, to an area that is a privately owned public open space. This shared, narrow, multipurpose area also needed to be sustainable, complete with a sophisticated recycled grey-water system for land irrigation, among other things. Munden Fry Landscape Associates was able to meet the challenges of designing for sustainability using AutoCAD, creating a beautiful outdoor garden setting with ample seating for Pinterest employees, the surrounding community and the public to enjoy.

Balancing the challenges of space constraints, the environment and public access

This unique space – a narrow pedestrian alleyway that connects Pinterest on Brannan Street to Bluxome Street – needed to function for multiple uses and serve multiple surrounding companies and many passers-by. Creating a design to meet various needs and purposes was critical and required a cohesive, aesthetically appealing design. Other challenges were inherent with the tight space, including a property line and creating a grey-water system.

Alexandria Real Estate Equities, Inc. (which owns, operates and develops the property) and developer TMG Partners turned to Munden Fry Landscape Associates (MFLA) to solve the design challenges of this privately owned public open space. Marta Fry, who heads the design firm with James Munden, is no stranger to urban projects.

“The planning process for this project was really complex,” Fry says. “But we knew we had to make this customised space really special and even more interesting given Pinterest’s brand cachet. We had to think through circulation and flow, particularly in light of the area businesses that would be using it as a pedestrian passageway.”

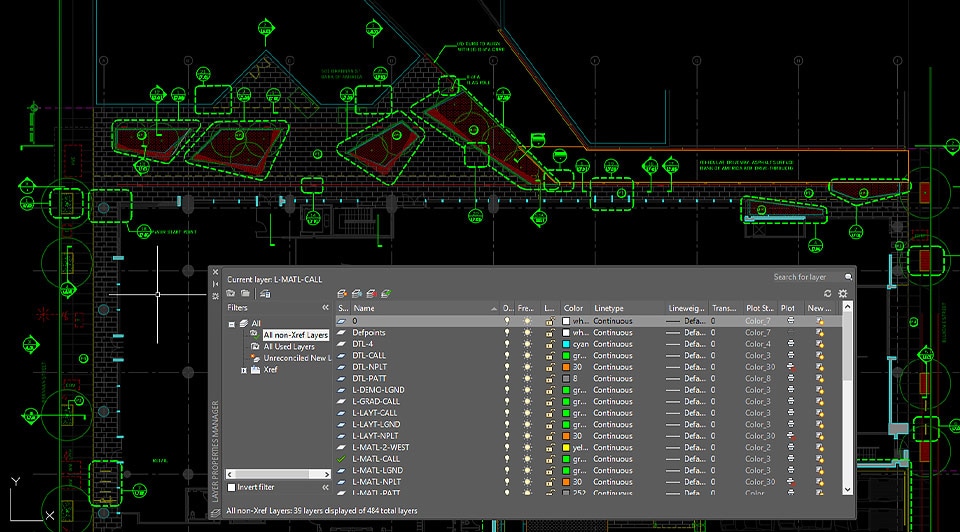

AutoCAD drives design and collaboration between architects and fabricators

While MFLA excels at urban and master planning, having developed projects throughout the San Francisco Bay Area and internationally, what makes this project unique is the close collaboration between landscape architects and the fabrication process. “A project like this does not always follow a linear process,” Munden says. “There’s a lot of back and forth involved in bringing ideas forward and in how the design ultimately gets developed. AutoCAD provides a common ground to help everyone stay co-ordinated and automates things. It brings all the technical layers together and ensures accuracy when multiple groups are working together on a project.”

The construction process is a good example of how AutoCAD was instrumental to this project. “When it came to realising MFLA’s vision, the design called for very complex geometry in the construction of the planters and bench areas,” says Adam Grove, design director for fabrication shop CW Keller & Associates. “The design parameters for the space called for extreme precision, which is where AutoCAD really shines. The architects were able to transfer drawing files as part of the review process, which allowed us to go back and forth and co-ordinate our work.”

Munden reinforced the importance of knowing where things stand in real time for such an intricate project. He explained that MFLA starts with sketches before moving to model forms. The real challenge is in transcribing this information and coordinating between disciplines – in particular the architect, civil engineer, structural engineer and fabrication team. AutoCAD is instrumental in achieving the accuracy required and the collaboration from design through construction. “No one knows what it takes to build these projects,” Fry says. “AutoCAD allows us to put together layers that are ‘visually buried,’ such as drainage or electrical systems, in a very precise and accurate way. We are able to not only connect the dots, but also make and track changes efficiently. The level of precision this supports is a game changer.

“I depend on my team to use AutoCAD,” Fry adds. “Our projects are inherently complex; they are layered with lots of different disciplines. With AutoCAD, we can put all those layers together in a very precise and accurate way that we didn’t have in the past when we were only doing hand drawings. By using AutoCAD, we have the precision for all of the different components from mechanical to electrical, architecture and the landscape itself.”

Drainage is not as simple as it looks

Most importantly, the space incorporates one of MFLA’s design principles: sustainability. One of the complexities of the project was the need to meet rigorous water-management standards and incorporate a unique recycled grey-water system that would be used for landscape irrigation and within the Pinterest building for toilets. But a property line that dissects the passageway proved to be a big challenge, and a seemingly simple drain is much more complicated than it appears.

“Storm water collected on a property needs to stay on that property and get treated on that property – you can’t disperse it,” Munden explains. “We created a high point in the centre of the space where the property line is and created a dual-drain system. There’s a slot drain that runs the total length of the city block that collects the water on the Pinterest property. It then goes to a holding tank beneath the ground lobby in the basement for processing.

“This is not the kind of drainage system that you can just draw by hand,” he continues. “With AutoCAD, we were able to precisely and exactly work within the constraints of the space and the property line and then communicate this to the contractors. This kind of accuracy is absolutely critical.”

An open space for everyone

Today, the passageway that connects Brannan Street to Bluxome Alley is both a garden retreat and a circulation spine to the new Pinterest headquarters. Fry calls it “a place to pause and sit, as well as have a more creative expression.”

Designed to be both a connector and an extension to the transparent Pinterest lobby, the site is composed of angled steel planters embedded with cedar benches, forming a complex geometry and relationship of planter to seating.

The design intent utilises the planters to spatially organise circulation and define axes, while the sculptural benches provide an integrated seating system, creating a suspended or cantilevered effect. Multitrunked paperbark maple trees (acer griseum), underplanted with autumn ferns (dryopteris erythrosora), thrive in this eastern exposure. New streetscape frontages at both Brannan and Bluxome, and a private rooftop terrace, complete the space.

“We feel fortunate to be a part of the SoMa [South of Market] community and we try to be engaged neighbours,” says Charlie Hale, head of public policy and social impact at Pinterest. “We’re happy to bring an indoor and outdoor public space to the neighbourhood, where people can eat lunch, have coffee or just relax.”

Discover the power of AutoCAD

Speed up and streamline your workflow with a subscription to AutoCAD including specialised toolsets.