Keyboard ALT + g to toggle grid overlay

Enhance programming efficiency

Automate your workflows to reduce your programming time, remove repetitive tasks and reduce errors.

Deliver superior parts

Produce high quality finished parts, with capabilities that increase the effectiveness of your NC programs.

Avoid overpriced software

Get access to advanced functionality only when you need it. Stick to your budget without cutting costs elsewhere.

Overview

Programming Automation

4-axis Rotary

5-axis Machining

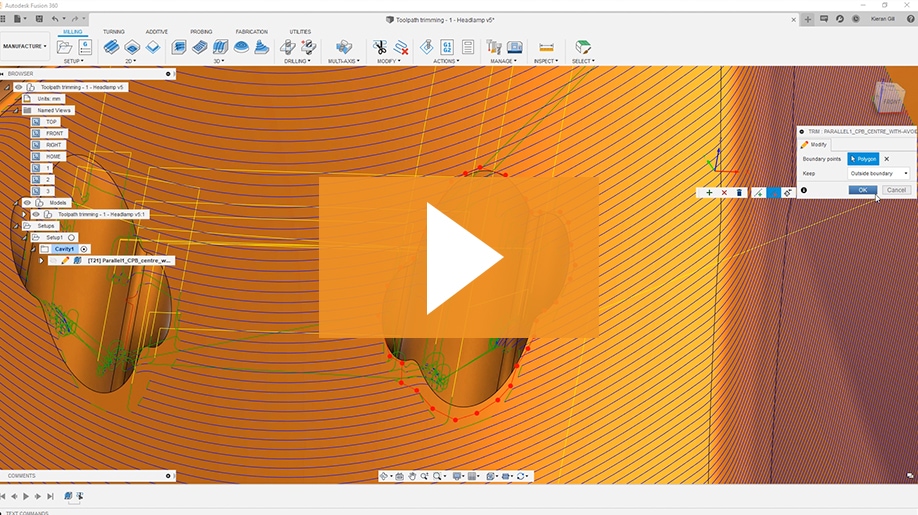

Toolpath Modifications

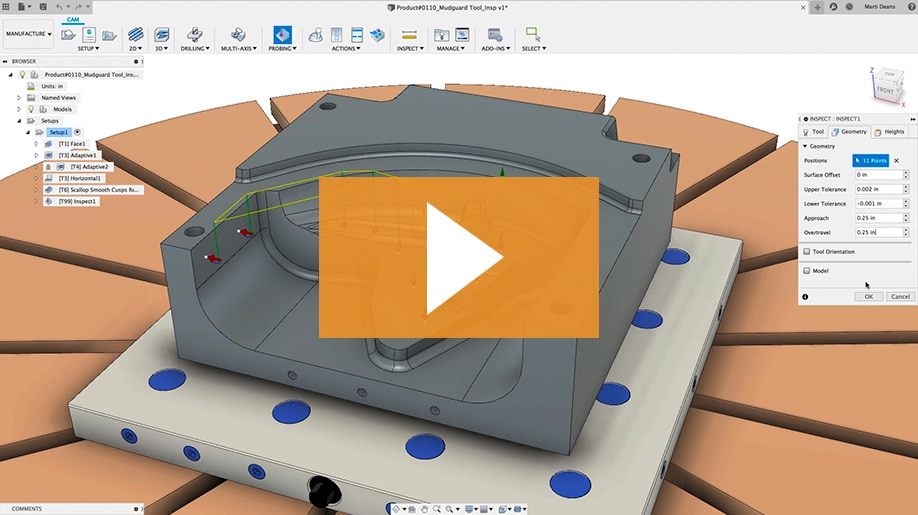

On-Machine Verification

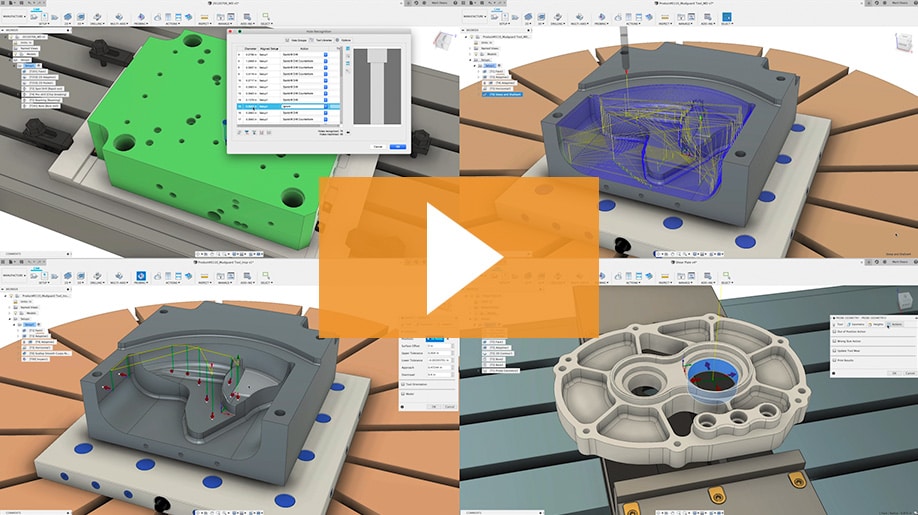

Overview

Extend the CAM capabilities of Fusion 360 with more advanced manufacturing technologies, including 5-axis programming, toolpath optimization, process automation, on-machine verification, and more.

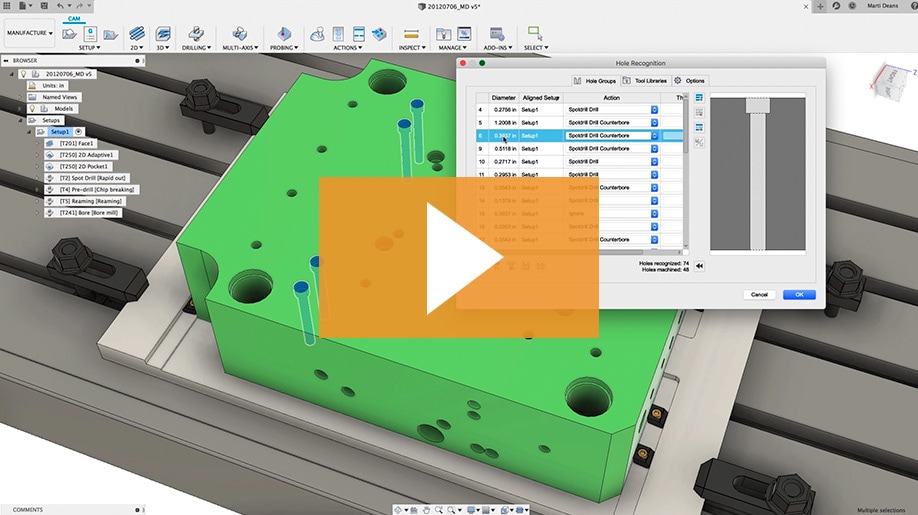

Programming Automation

Simplify and speed up drilling by automatically recognizing holes, selecting tools, and ordering operations efficiently for faster cycles.

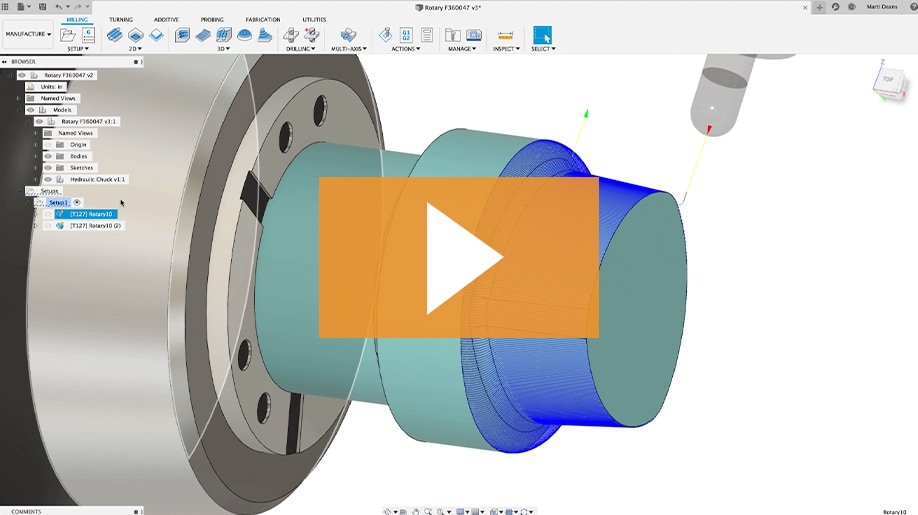

4-axis Rotary

Produce efficient 4-axis toolpaths to machine revolved parts, or those with a centerline axis. Choose from a range of Rotary toolpath strategies to suit your CNC machine.

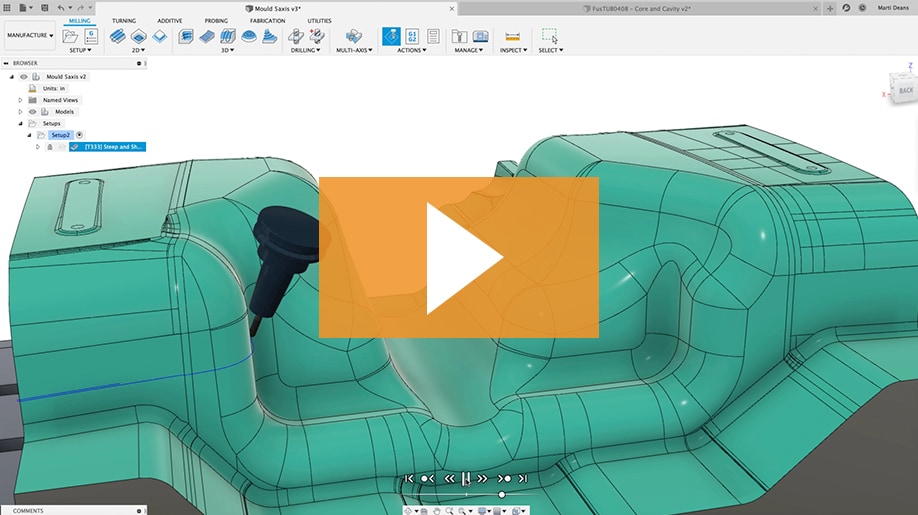

5-axis Machining

Improve surface finish and increase cycle efficiency with advanced 5-axis controls for Steep and Shallow toolpaths. Machine complex parts safely with full 5-axis collision avoidance.

Toolpath Modifications

Simplify programming by quickly trimming selected areas of toolpaths inside or outside a sketched boundary. Trim operations automatically add new, gouge-free leads and links without needing to recalculate the entire toolpath.

On-Machine Verification

Streamline your verification process with surface inspection and probe geometry. Free up time for more reliable unattended machining.

"It’s a game changer for me. I just have more power to take a concept, model it up, and then take it to a CNC machine."

- Christian Welch, Swissomation

Get it now

FUSION 360 - MACHINING EXTENSION

FUSION 360 - MACHINING EXTENSION

Extend the CAM capabilities of Fusion 360 with more advanced manufacturing technologies, including 5-axis programming, toolpath optimization, process automation, on-machine verification, and more.

Requires a Fusion 360 subscription.