Keyboard ALT + g to toggle grid overlay

Finite element analysis software

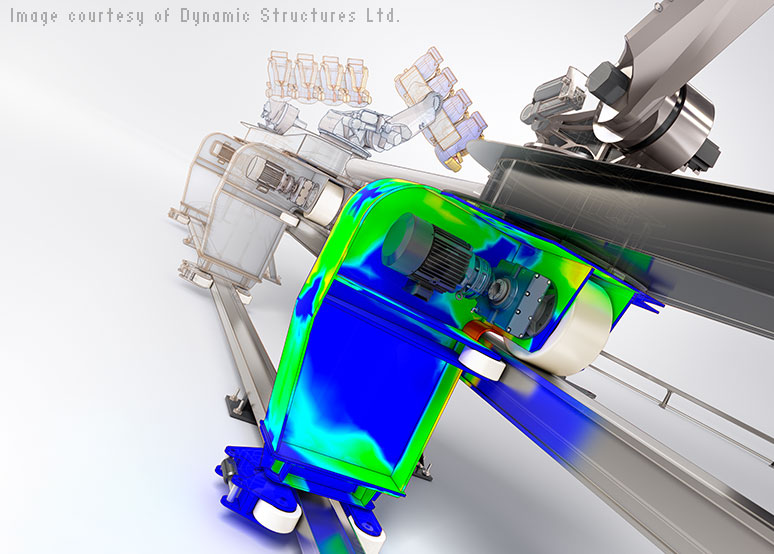

Finite element analysis (FEA) is a computerised method for predicting how a product reacts to real-world forces, vibration, heat, fluid flow and other physical effects. Finite element analysis shows whether a product will break, wear out or work the way it was designed. It is called analysis, but in the product development process, it is used to predict what's going to happen when the product is used.

EA works by breaking down a real object into a large number (thousands to hundreds of thousands) of finite elements, such as little cubes. Mathematical equations help predict the behaviour of each element. A computer then adds up all the individual behaviours to predict the behaviour of the actual object.

Finite element analysis helps predict the behaviour of products affected by many physical effects, including:

- Mechanical stress

- Mechanical vibration

- Fatigue

- Motion

- Heat transfer

- Fluid flow

- Electrostatics

- Plastic injection moulding

Autodesk solutions for manufacturing

See how the Autodesk solution for digital prototyping is helping manufacturers design, visualise and simulate consumer products, industrial machinery, building products and more.

Finite element analysis & simulation software for product design

The Autodesk Simulation family of products delivers a comprehensive set of finite element analysis and simulation software tools that are easy to integrate into each phase of the product development process. From mechanical stress, vibration and motion to computational fluid dynamics, plastic injection moulding and multiphysics, finite element analysis and simulation software (US site) from Autodesk provides a fast, accurate and innovative approach to solving your most challenging design problems.

Simulation Mechanical

Study finite element analysis (FEA) and mechanical event simulation.

CFD, CFD Viewer

Use computational fluid dynamics models to compare design alternatives.

Moldflow

Optimise and validate your injection moulding process.

Inventor Professional

Develop, manage and deliver great products with digital prototyping abilities.

Subscribe or try for free

Product Design & Manufacturing Collection

Get an essential set of product design, simulation and engineering tools at a great price.

Subscribe or learn more

Robot Structural Analysis Professional

Calculate and analyse large, complex structural models.

Finite element analysis & simulation software for students

Students can push the boundaries of finite element analysis and simulation with Autodesk software. Download the same, full version software that more than 9 million designers, engineers and digital artists are using, including Autodesk Inventor Professional, Autodesk CFD, Autodesk Moldflow Advisor Ultimate and Autodesk Robot Structural Analysis Professional software.

Download free software (US site)

Lorem ipsum dolor sit amet

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua.

-

What is finite element analysis (FEA)? Finite element analysis uses computer software to predict in a digital space how objects will react to real world factors such as heat, vibration and motion.

-

What is finite element analysis used for? Finite element analysis can be used to check whether a product works as expected, and to inspect wear or breakage patterns.

-

What factors can FEA consider? A wide variety of factors can be modelled using finite element analysis, including mechanical stress and vibration, heat transfer, fatigue, motion, fluid flow and electrostatics.

-

Are there any cost-effective FEA solutions for students? Yes – students can download a full suite of Autodesk products for FEA for free, including AutoDesk Inventor Professional and Autodesk Moldflow Advisor.