Keyboard ALT + g to toggle grid overlay

How digitalisation helps your industrial equipment business

-

Be a full-service solutions provider

Extend and customise your offerings around the business goals of your customers. Meet or exceed the requirements of every project and help customers achieve better results.

-

Increase operational efficiency

Optimise manufacturing productivity without compromising quality. Reduce downtime, improve lead times, maximise your resources and deliver high-quality products on time.

-

Make better products

Making highly complex products is not easy. Equip your team with the latest advancements in design and manufacturing technology to save time, reduce costs and get better products to market.

Transform your product development process

Digitalisation is reshaping your industry right now, which means the time to adapt your business is today. You need to be able to:

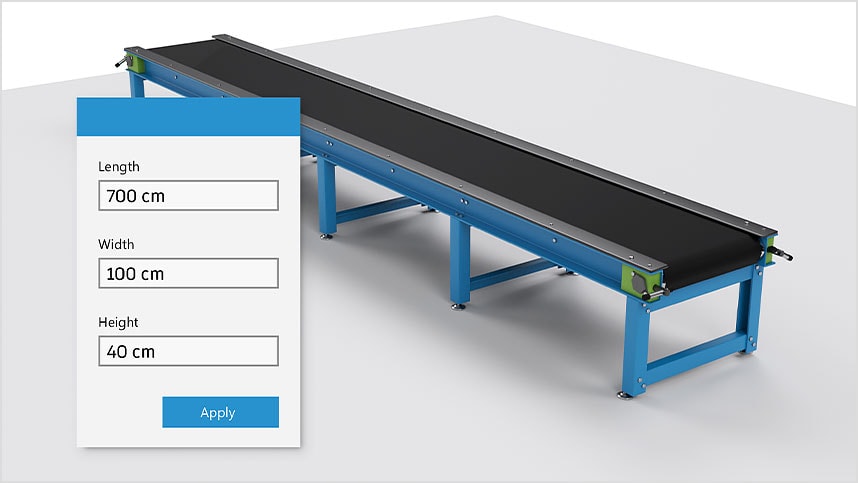

Meet the demand for customisation

Customers are no longer looking for mass-produced products. They want complete solutions customised to their specific production objectives. Manufacturers can use automation to configure products faster while keeping the cost of customisation down.

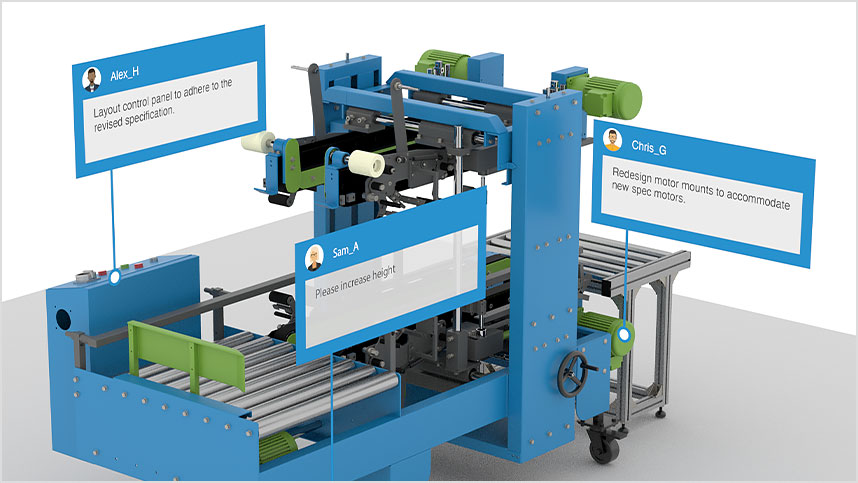

Collaborate more efficiently with internal teams, suppliers and customers

Product development includes a lot of stakeholders who need to be able to collaborate earlier and more often. Digitalisation can bring together all the data, people and processes involved – without putting intellectual property or time to market at risk.

Quickly adapt your manufacturing processes

New materials and production methods are creating more possibilities for manufacturers. At the same time, the pace of manufacturing is only getting faster. Advanced manufacturing technology can help you be agile and innovative in this quickly changing environment.

Offer more value to your customers through your products and services

Your customers are looking to you for complete production solutions. To understand their business and deliver on their vision, manufacturers will need to free up capacity to customise products, create more innovative solutions, extend service offerings and connect to their digital ecosystems.

Let’s talk strategy

How mature is your product development process? Autodesk can help you strategise for digital transformation and develop the capabilities needed to achieve your goals. Keep in touch today to schedule your business consultation.

Thanks for keeping in touch. Someone from our team of technical and business experts will be in touch soon.