Keyboard ALT + g to toggle grid overlay

Simulation software

Our comprehensive simulation portfolio offers software for mechanical simulation, computational fluid dynamics (CFD), plastic injection moulding, composite materials, structural and manufacturing simulations.

-

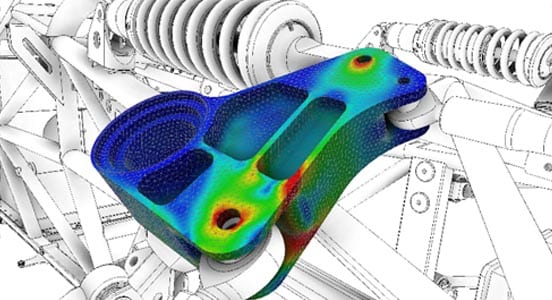

Finite element analysis

Use comprehensive finite element analysis (FEA) to predict product performance through linear, non-linear, thermal and dynamic analyses. Optimise designs and validate product behaviour before manufacturing.

Inventor Nastran

See Fusion 360 (US site) -

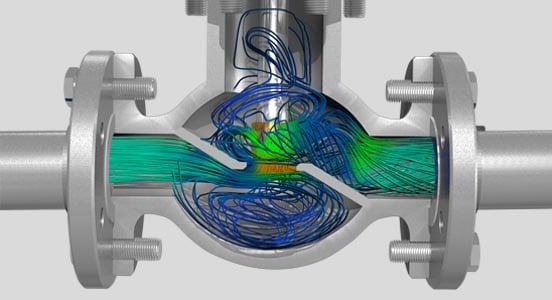

Computational fluid dynamics

Accurate and flexible software for fluid dynamics, thermal management and airflow analysis. Solve, analyse and make decisions earlier in the product development process.

-

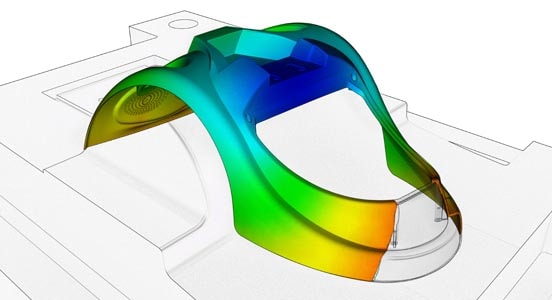

Plastic injection moulding

Simulate your complete plastic injection moulding process. Optimise your part design, mould design and manufacturing process. Create high-quality plastic products and avoid potential manufacturing defects.

-

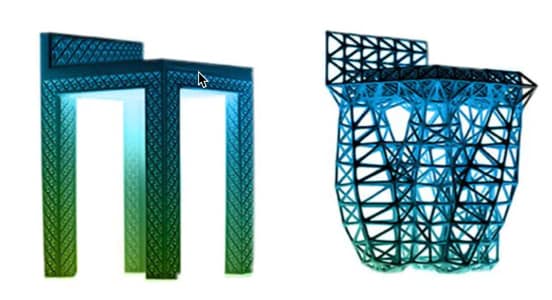

Generative design

Expand your ability to deliver innovative design and engineering solutions. Simultaneously generate multiple CAD-ready solutions based on manufacturing constraints and product performance requirements.

Solutions

-

Mould cycle time

Reducing seconds out of a cycle time can dramatically increase the profitability of a job and lower the piece part cost.

Learn more (US site) -

Electronics cooling

Electronics within products are constantly changing and improving. Proper cooling of these components remains key to producing a successful product.

Learn more -

Fluid flow

Predicting fluid flow rates, pressure drops and turbulence are just a few items that are challenging to measure during design.

Learn more (US site) -

Automotive lightweighting

Physical prototyping and testing are costly and time consuming. Simulation lets you explore automotive lightweighting opportunities.

Learn more -

Product performance

Using simulation-driven design throughout the design phase lets you make informed decisions while exploring the realm of the untested.

Learn more (US site) -

Building HVAC

Building codes and owner expectations are driving new ventilation challenges. Engineers can simulate HVAC performance to optimise designs. -

Generative design

Quickly generate high-performing design alternatives – many that you would never think of on your own – from a single idea.

Learn more (US Site) -

Plastic part quality

Manufacturing high-quality depends on interrelated factors that can affect the performance and aesthetic appeal of injection moulded plastic parts.

Learn more (US Site)

Resources

-

11 factors for efficient mould cooling

Small changes in cooling can have a big impact on cycle time. Get an overview of how you can maximise cooling efficiency to produce higher-quality parts more quickly.

Download eBook (US site)

-

4 ways every engineer should use simulation

Engineers make critical design decisions every day, while engineering the products of tomorrow. Learn 4 ways every engineer should use simulation to make more informed decisions.

Download eBook (US site)

-

The next wave of intelligent design automation

Imagine a world in which you can direct creative focus to what you build rather than how. Sound far-fetched? Take a look into this world.

Download eBook (US site)