Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

Design engineers create custom skull implants using digital fabrication and automotive-industry expertise

Carlos Monroy and Martín Carcaño of Granta applied their backgrounds in the aircraft and automotive industries to develop an innovative method of medical-implant design and fabrication. Their custom skull implants fit precisely during surgery and reduce the risk of patient rejection. Using the latest software and digital-fabrication tools, the Granta team is improving the quality of their patients’ lives—and changing their own lives in the process.

A background in engineering, a desire to help people

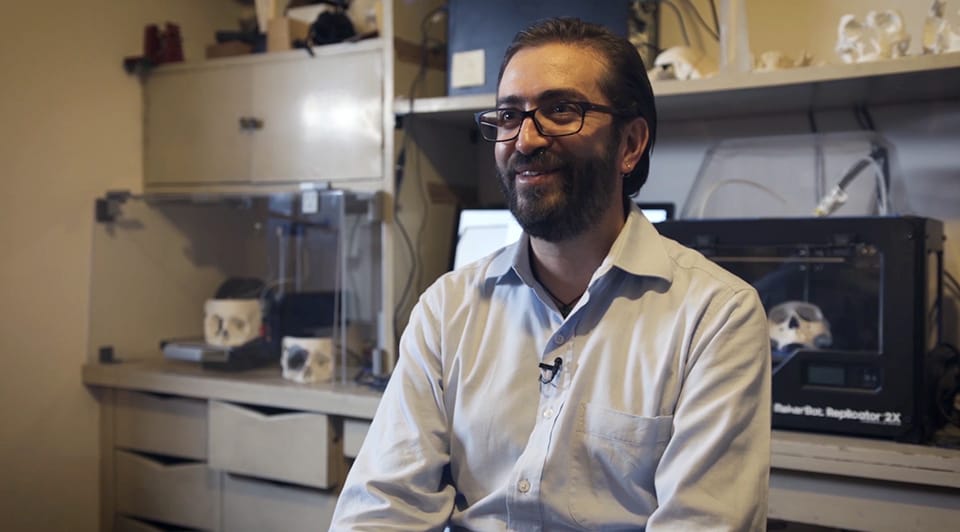

Carlos Monroy’s studies in engineering and design took him from his native Mexico to a PhD from the University of Cambridge in the UK. He’s worked in the aircraft industry, the automotive industry, and high-end sports. “But since I was little I wanted to help people,” he says. “I wanted to contribute something to society.”

As his studies advanced, Monroy’s interests began to converge in new ways. “When I was doing my second post-doctorate degree, we started to transfer the technology we were using for the automotive industry to other sectors,” he says. “We translated it to medical devices—we knew there were a lot of things that we could help with.”

Monroy returned to Mexico and started a business developing medical devices, following his childhood ideal of helping people. Named Granta, after a stretch of river near the University of Cambridge, it would blend his work with automotive materials with new advancements in digital fabrication. He was joined by Martín Carcaño, a mechanical engineer and industrial designer with more than 10 years of experience in the automotive industry—and an expert in CAD/CAM and digital manufacturing technology.

Improving lives with technology

The vision behind Granta is to improve people's lives by designing and fabricating customized bone implants for patients who desperately need them. Monroy decided the best place to begin was with skull implants. “It’s the easiest place for us to start because it’s so important to protect the brain, but you don’t have any other joints or articulations,” he explains. “It’s there to protect, and as long as you accomplish that, it works.”

Granta is one of only six or seven companies around the world that design custom skull implants. “We’re the first one to get all the approvals and permits needed by the Mexican government to do this type of implant,” Monroy says. “We design and manufacture everything in-house.”

There were many challenges along the way. “It’s difficult to start a company, and even more difficult to start a company in the health sector in Mexico,” he says. Granta had to pass multiple government inspections and complete piles of paperwork to get all the necessary permits. But after two years of waiting, the company received the approvals from the Mexican government. Soon after, a local doctor contacted Monroy—and Granta had its first patient.

Treating serious head trauma

Adriana had been living a normal life in Mexico City with her husband and family when she suffered a life-threatening brain aneurysm. After surgery to repair the injury failed, doctors had to perform a craniotomy, a procedure to remove part of her skull to relieve the pressure in her brain and save her life.

To replace the bone, she was initially given a skull implant made from PMMA (polymethyl melacrylate), an acrylic that’s molded to the patient’s cranium during surgery. However, this material is susceptible to bacterial growth and water absorption. Adriana suffered a secondary infection from the PMMA implant and required emergency surgery to remove it.

With her skull lacking the support and protection of an implant, Adriana’s health continued to decline. After a year, she had lost the ability to speak and control the left side of her body. Desperate for a solution, her worried family jumped at the chance to work with Granta.

A custom implant created with CAD

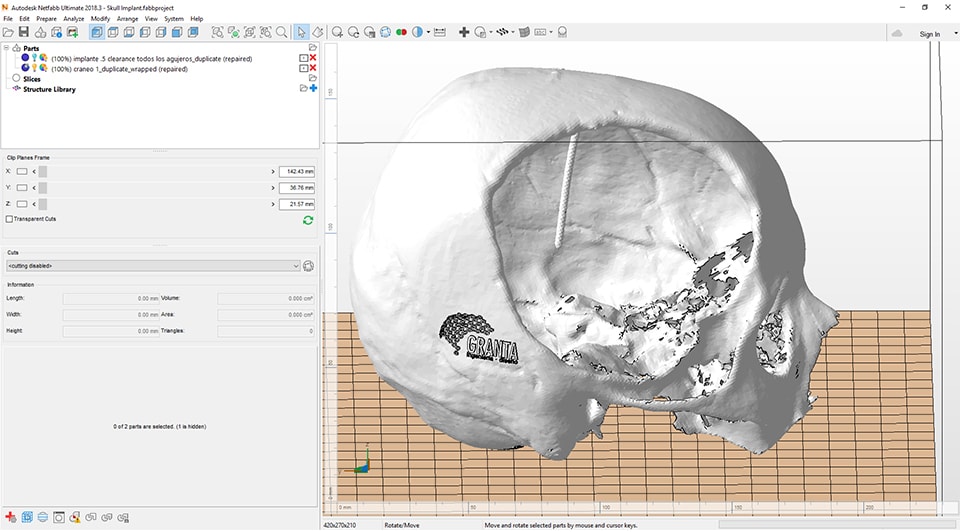

The implant that Adriana would need “was very, very tough because it’s not a small implant,” says Martín Carcaño, head of biomedical design at Granta. “It’s pretty much half of the skull, so that was challenging.” Monroy and Carcaño got to work on the implant after they received a CT scan from her doctor, which they converted to point-cloud data and used Netfabb to prepare the file for import into design software. Using Inventor and Fusion 360, a custom implant was designed to fit the exact size and shape of Adriana’s skull.

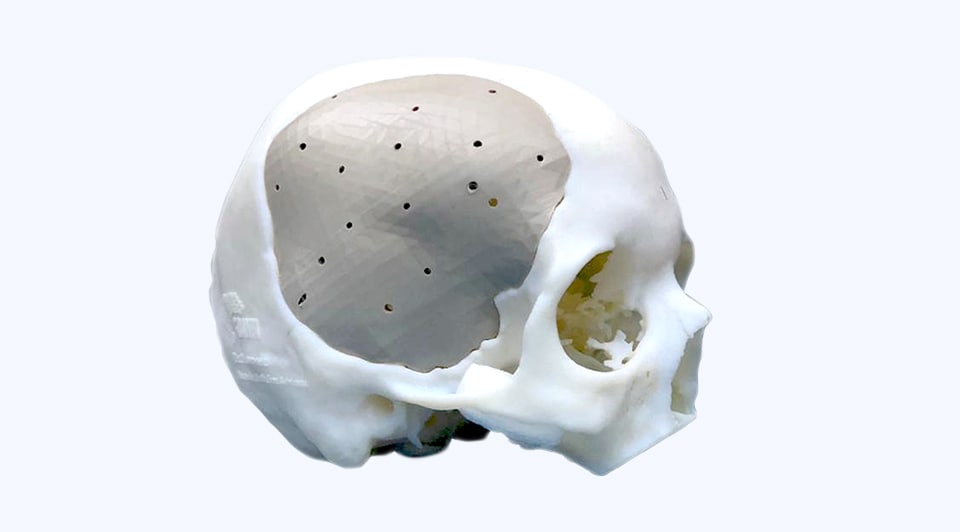

Next, they 3D printed a model of the skull and the implant, then they reviewed the prototype and digital file with the doctor to make modifications. “Imagine designing something with 0.05 mm tolerance in the fit, with no access to the part itself,” Carcaño says. “It’s the human skull—you can’t just cut the tissue and take measurements. We depend entirely on digital data. There is no room for error; one mistake, and it’s the end.”

Once the design was finalized, the next challenge was to fabricate the implant, with its complex organic shape. “We use a material that is completely biocompatible called PEEK—polyether ether ketone,” Monroy says. “One of its properties is that the body will not attack the material, and it will not produce an infection.”

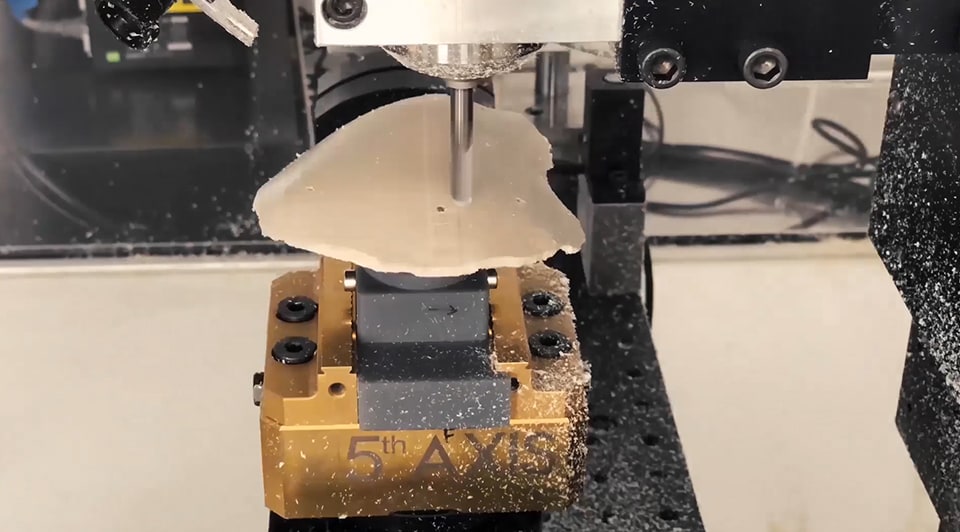

Using PowerMill, the Granta team milled the PEEK with a five-axis CNC machine to match the 3D model. To ensure the accuracy of the fit, the team 3D scanned the implant with ReCap, which creates a virtual model of the physical part to compare to the digital design file. Everything matched up, and the implant was sent to the hospital to sterilize and prepare for Adriana’s surgery.

From digital to reality

Adriana’s implant surgery, called a cranioplasty, took place on September 18, 2018 at Español Hospital in Mexico City. A cranioplasty usually takes six hours or more to perform with a traditionally designed and fabricated skull implant because it requires the neurosurgeon to spend a significant amount of time shaping it to fit.

With Granta’s implant, designed from the start for a perfect fit, the entire surgical process took less than three hours. “At that point everything became so real,” Monroy says. “Being able to see the implant being fixed to her skull in less than four minutes, and perfectly without any complications. I couldn’t believe it. Everything made sense.”

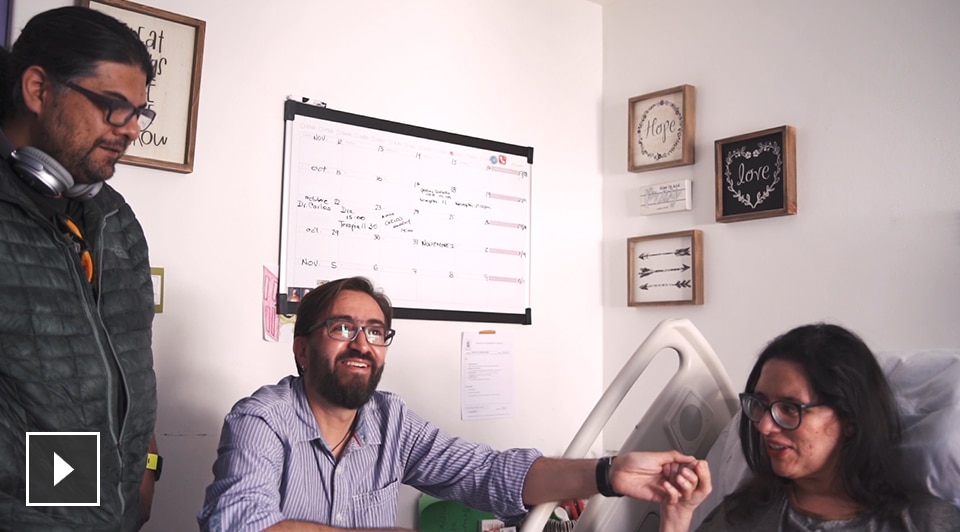

Following the surgery, Adriana’s condition began to improve. Monroy and Carcaño went to meet her in recovery the next day. “She received me with a huge smile, and said, ‘Thank you for what you have done for me, you have changed my life,’” Monroy says. “And in reality, it’s the other way around.”

“All my life I’ve been doing design engineering for commercial products: automotive, product design,” Carcaño says. “Yes, you feel that you have an impact in the world, that you’re designing stuff that people are using. But when you design something that is so critical for a human being—I mean a part that he or she relies on to live—that’s a life changer.”

Next for Granta

Since Adriana’s surgery, the Granta team has gone on to help more patients. Four more people have already received custom implants, and several other cases are in development. Monroy is also excited about exploring new technologies and materials, including 3D printing directly in PEEK and in titanium. “That's something that I have been discussing with a maxillofacial surgeon, for people that lose part of the jaw because of a tumor,” he says. “I just need to find the right combination of materials.”

As the company evolves, “I don't want to think of Granta as just an implant company,” Monroy says. “We’re looking at what’s next, what else can we do with this technology that will allow us to help other people. We want to change people’s lives and improve the quality of how they live.”