Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

Digital construction planning leads to improved project quality, reduced rework, and less material waste

China First Group executed the complex construction of the Jingdezhen Imperial Kiln Museum using BIM solutions and the tools provided in the AEC Collection. Their approach to preconstruction provided cost, schedule, and material efficiencies in the field—all while avoiding damage to surrounding historical buildings.

A vision tied in rich history

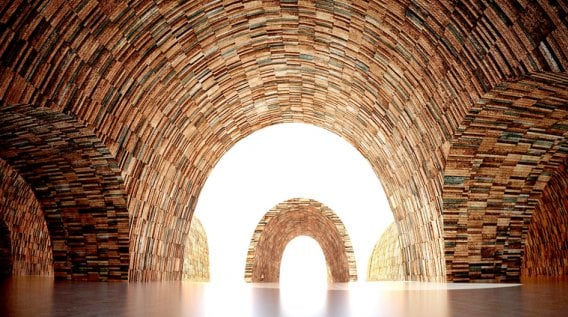

One of China's leading architects, Studio Zhu-Pei, developed a vision for the Jingdezhen Imperial Kiln Museum that borrows from the rich porcelain manufacturing heritage of Jingdezhen, the city in which it is housed. Jingdezhen, located in Jiangxi province, has manufactured fine porcelain for at least the last thousand years, and the region is rich in clay deposits. As a nod to this history, the museum's eight curved structures, lined with 300-year-old kiln bricks, replicate a Jingdezhen kiln.

China Construction First Group, a world-renowned residential and infrastructure construction management company, realized Zhu-Pei's vision, overcoming unique challenges throughout the process. The inclusion of these rare, nonrenewable materials and the need to treat a culturally valuable site with the utmost care heightened the need for quality throughout the project. The team, led by BIM manager RenWei Wan, used a range of Autodesk products and building information modeling (BIM) to successfully deliver a distinctive, high-quality project.

Solving unique preconstruction challenges with BIM

Before construction could start, the team had to address three primary challenges: protecting the site’s ancient heritage, controlling the quality of the curved structural design, and limiting quantities of the building material. The team used BIM and Autodesk's AEC Collection to alleviate and address each of these preconstruction challenges:

Protecting the site's heritage

Jingdezhen's ancient city wall, built during the Ming dynasty (1368-1644), surrounds the museum site. While some of the wall had to be excavated to construct the main transportation intersection, any further disruptions to the wall needed to be avoided. Complex traffic patterns downtown also necessitated a careful evaluation and modeling of the environment using BIM to develop and optimize alternative traffic flows.

The team used an unmanned aerial vehicle to collect oblique photographs of the construction site and plugged them into Autodesk ReCap. The result was a real-scene model of the construction site and the surrounding neighborhood. Using Autodesk tools in this manner allowed the team to see available roads and plan a transportation route for the city that minimized both the impact on residents and damage to precious cultural artifacts.

Quality control of curved structures

Constructing the curved structures that replicate ancient kilns was complicated because each of the eight units had varying curvature, changing every 50 cm (less than two feet). An approximately 400-meter-long (1,300-foot) arch had more than 800 sections and 14,000 surveying control points, presenting a daunting surveying and mapping task.

Autodesk Revit helped model the arch framework and analyze frame joints and stress conditions. The team used Revit to design the sliding-track-type adjustable curvature framework that was unique to this project. They then fine-tuned the model until it met the design parameters.

The team further exported Revit models to virtual and mixed-reality platforms for collaborative communication and simulation demonstrations with design and construction professionals. Designers used virtual reality (VR) to simulate the effects of weather on natural light feeding the museum and allowed them to configure lighting systems accordingly.

Limited quantities of the building material

The architect's vision involved constructing the museum using ancient kiln bricks. Given the limited availability of this valuable cultural resource, the team could not afford any waste during construction.

Autodesk Navisworks facilitated simulation of construction workflow processes, which prevented potential design errors and rework headaches. Revit helped to accurately gauge the design requirements for the ancient kiln brick curtain walls. This reduced brick loss from processing and installation by 10%—a critical amount of savings given the nature of the nonrenewable, ancient building material.

"Using the openness of Autodesk software, the team implemented a BIM-based quality control Plan-Do-Check-Action (PDCA) workflow," RenWei Wan said.

BIM helped in all aspects of preconstruction. Overall, it improved project quality by reducing rework in the field and digitally modeling construction workflows.

On a similar project, such a special structure would increase the labor workload of surveying and mapping by more than three times.

—RenWei Wan, BIM manager, China Construction First Group

Autodesk BIM solutions deliver tangible benefits

Using BIM in all aspects of preconstruction delivered efficiencies across the board. These include:

Improved multi-party communication efficiency.

Visual simulation of different types of models, including BIM modeling, reality capture, and 3D scanning point cloud, improved communication efficiency between designers, contractors, and construction field personnel by more than 50%, according to team estimates.

Reduced design errors

Preconstruction BIM simulations of the structures, curtain wall, and electromechanical specialties reduced design errors by 30% and saved the loss of nonrenewable materials, including ancient kiln bricks, by 20%.

More efficient field surveying and mapping

Using data collected by a surveying robot, setting-out work was conducted in a 3D space using BIM, which improved the efficiency of surveying engineers by 70%. Additionally, 3D scanning combined with BIM realized accurate checking and surveying of special-shaped arch structures and shortened the surveying duration by 50%.

Easier cost estimates

Due to the unique structures at play, the cost engineer initially could not accurately estimate material costs. After training as a professional BIM engineer, he used virtual takeoff and quantification capabilities in Navisworks to calculate the amount of concrete, formwork and mechanical and electrical pipelines needed for the multi-curved arches with variable curvature.

Improved quality control

Revit modeling delivered control over construction quality and accuracy, especially when analyzing arch formwork frame joints and stress conditions. The developed variable curvature adjustable formwork system received a patent license and is expected to create a return on investment of 2 million renminbi (RMB).

Project delivered on time

The AEC Collection's integrated BIM workflows facilitated innovative structural formwork engineering that contributed to a full 58 days of time savings.

A model for using technology to handle cultural needs

Because of the historical value of the buildings near the museum, the team had to be extra cautious in its approach to construction.

Project quality was even more critical than usual. Given that the architectural design fit in so well with the surroundings and emphasized the historical connection to the city, the construction had to as well.

This approach shows how teams can leverage modern technologies like BIM to execute complex construction without damaging historical buildings and gaining other efficiencies along the way.