& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

AECO

Global architecture firm Populous borrows concepts from industrialized construction and product manufacturing to build transformative, eco-friendly sports complexes—and deliver them faster, cheaper, and better.

AECO

An ancient ceramics factory has a new life as Taoxi Mingzhu, a modern mixed-use complex. Discover the challenges and innovations behind this architectural feat.

Emerging Tech

Designing Beijing’s new Sub Center Theater complex meant using smart construction technologies to perfect everything from architecture to acoustics.

Image courtesy of Royal BAM Group

“Autodesk construction solutions give us visibility on risk and a higher degree of focus. Insight is identifying the problems and constraints that now act as leading KPIs for BAM to identify hotspots, rather than relying on traditional construction intuition. We’re having less reactive conversations with more emphasis on KPIs that can drive continual improvement.”

— Michael Murphy, Digital Construction Operations Manager, BAM Ireland

PD&M

At Kia Global Design, generative AI is helping automotive designers ideate and innovate faster, accelerating the process of taking a design from initial concept to final form.

PD&M

Cosmic Robotics, an Autodesk Research Residency Program member, uses advanced robotics and cutting-edge hardware and software to develop robots that can take on the labor-intensive task of solar farm construction.

PD&M

With a unified cloud platform for collaboration among product designers, Native Instruments provides musicians with the hardware and software to find the perfect sounds.

Image courtesy of Hyundai Motor Group

“Generative design helps the human mind expand the range of possibilities. With the help of generative design, a single designer or engineer can go through perhaps dozens or hundreds of different design iterations, so it enables them to see things that they may not have otherwise considered, and in tandem tackle complex problems. Which is to say that people still have a very important role to play in shaping the design direction. There will always be need for the human eye, the heart, and the soul as vital parts of the design process.”

— John Suh, Founding Director of the New Horizons Studio, Hyundai Motor Group

M&E

For its recent game New Tales from the Borderlands, an automated pipeline helped Gearbox create 4x more cinematic gameplay in half the time–and enabled artists to spend 50% more time on creative work instead of logistics.

M&E

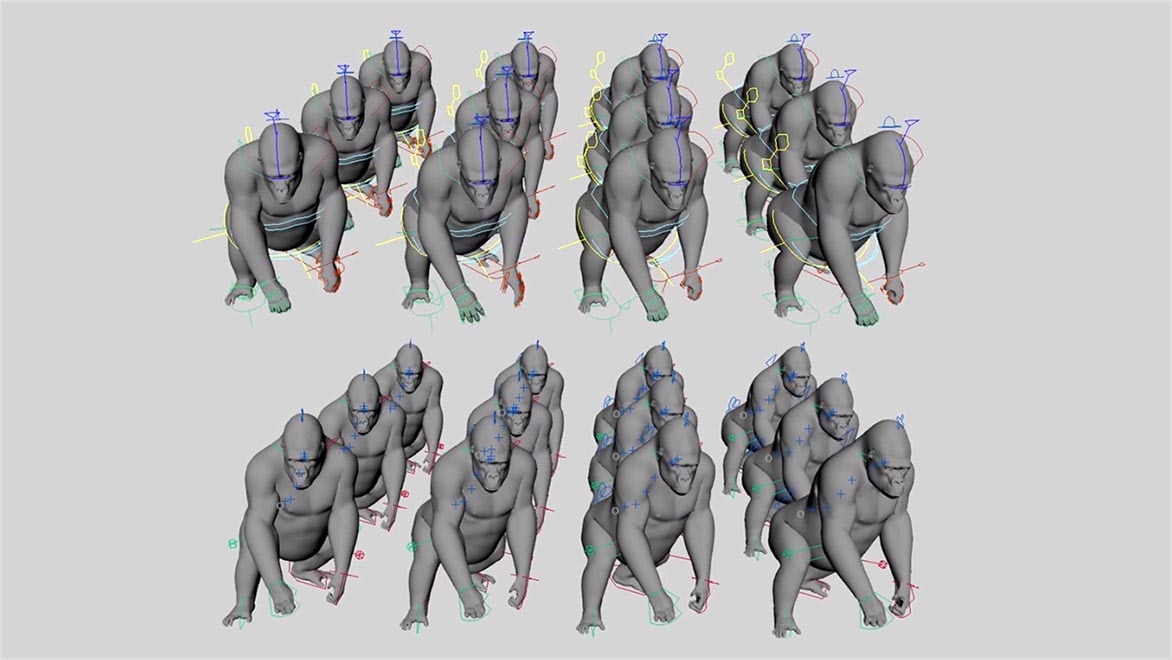

Find out how visual-effects company Wētā FX has driven performance-capture methods to new levels of realism in blockbuster franchises such as The Lord of the Rings, Planet of the Apes, and Avatar.

Emerging Tech

Disney innovation elevates storytelling and the creation of immersive experiences—processes that, in its theme parks, require extensive BIM coordination.

Image comparing Weta Koru (top) with Maya courtesy of Weta Digital

“(Weta Digital’s new Software-as-a-Service offering) WetaM will raise the bar for global creative production, redefining the industry in the process. At its core, this partnership with Autodesk will extend the reach of the Weta magic, making it more accessible for artists in pursuit of creating amazing characters and worlds across film and television.”

— Prem Akkaraju, CEO of Weta Digital.

Learn how people in a wide array of industries are using Autodesk products and solutions.

Meet the boundary-pushers who are transforming architecture, engineering, construction, product design, manufacturing, media, and entertainment.