Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

Manufacturer of heavy-duty electric vehicles for mining streamlines design and manufacturing with Autodesk Inventor and Vault

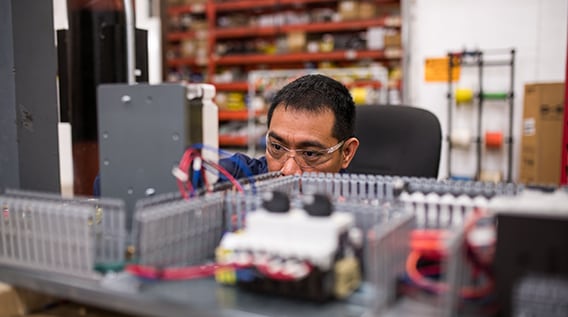

Rokion designs and manufactures battery electric vehicles (BEVs) for the mining industry–but they aren’t your ordinary BEVs. These specialty vehicles are unique in the market because from inception they are designed from the ground up as battery electric, while most competitors focus on retrofitting diesel vehicles with batteries. Designing “from the ground up” gives Rokion vehicles distinct advantages in terms of performance, reliability, and safety.

To manage the process smoothly and bring products to market as efficiently as possible, the company relies on the Autodesk Product Design & Manufacturing Collection, including Inventor, AutoCAD, and Vault for data management across the enterprise.

Carving out a niche through innovative design

Rokion, headquartered in Saskatoon, Saskatchewan, Canada, makes some of the most advanced battery-powered electric vehicles in the world for heavy industrial and mining applications. These utility and crew trucks are designed to handle the harshest mining conditions, climb the steepest ramps, and provide safe travel through every part of the mine, all while producing zero emissions.

What makes Rokion vehicles stand apart from the competition is the company’s approach to design and engineering. Most electric vehicle OEMs work backwards, starting with a diesel vehicle and stripping out the engine and transmission and then retrofitting an electric motor and batteries. This causes a lot of challenges with respect to battery capacity, because the original architecture of the vehicle was not designed to accommodate batteries.

“At Rokion, we design the vehicle from the ground up to be electric,” says Dave Cote, Applications Engineering Supervisor within Rokion R&D. “The frame, the drive train, the rollover protective structure, all of it. Instead of trying to convert a diesel, we began with a blank sheet of paper. That has allowed us to reserve more space for battery capacity and deliver the power necessary to get in and out of mines with very steep ramp access.”

Getting up and down these ramps takes enormous power, which Rokion delivers by adjusting the size of battery packs as well as selecting the appropriate battery chemistry for the application. Competitors can’t do this as easily because they are space-constricted, so they are often forced to use the highest energy density cells available—similar to the lithium, nickel, manganese cells used in on-road vehicles and consumer electronics.

“We design the space for the battery module so we can take advantage of lithium iron phosphate battery (LiFePO4) chemistry. LiFePO4 has relatively low energy density, however it is the safest chemistry commercially available, for Rokion, Safety is our first priority,” Cote says. “Safety is critical in underground environments, where a battery fire could be catastrophic. Designing from the ground up lets us deliver the highest level of safety which is what customers are looking for.”

Rokion vehicles are also unique in that they use dual motors. Standard four-wheel-drive trucks only have one, with a transfer case that diverts power front to back. As a result, when they run in four-wheel drive mode they tend to bind, skip, and hop when turning around sharp corners. With two motors, Rokion vehicles allow a slip between the front and rear axles to smooth out the ride.

Streamlining workflow from sketches to service

Rokion’s approach to product design relies on a combination of Autodesk Inventor for 3D modeling and 2D documentation and Autodesk Vault to manage the data and be the basis of collaboration between design and fabrication. The process starts when Cote’s R&D team begins rough modeling in Inventor, whether the concept is a new vehicle or an expansion of an existing platform. At this point, the team creates general arrangement drawings that show what the product will look like and how it will perform, including preliminary simulations of how steep a grade it can navigate or how many people it can carry.

“The pillar of our company is and has always been our engineering division, where we take a customer’s problem and we engineer a solution for it,” says Kipp Sakundiak, General Manager at Prairie Machine, Rokion’s parent company. “That's really where the Autodesk tools come into play.”

When the concept is approved to proceed, the Rokion team uses the 3D model created in Inventor to add more detail and determine where each part belongs in the assembly. From here, Cote’s team begins working with fabricators to create a prototype that can be further tested and evaluated. This starts a process of revisions, which are tracked in Vault. Eventually, the final details, such as harness routing, hoses, and fasteners, are finalized along with assembly instructions.

On the shop floor, Vault helps Rokion ensure that the design intent is translated faithfully for metal fabrication and welding.

The pillar of our company is and has always been our engineering division, where we take a customer’s problem and we engineer a solution for it. That's really where the Autodesk tools come into play.

—Kipp Sakundiak, General Manager, Prairie Machine, Rokion parent company

“We collaborate quite a bit with Research & Development because when that handover happens, it’s important to retain the intent of the design as we make revisions that will make the vehicle more efficient to build,” says Ryan Kolenosky, production engineering supervisor. “We used to work on 2D shop drawings, but now we’re getting into more 3D model sharing with Inventor. That’s working quite well, and we’re even working out how to get into 3D assembly prints.”

The product engineering team discovered the embedded tools within Inventor to create a variety of views alongside 3D annotations for assembly—which could be a part number, a dimension, or even the torque specification on a bolt—and it is much easier to deal with than a black-and-white 2D print.

Finally, every time Rokion engineers a part, it’s released in Vault and automatically transmitted to the company’s ERP system. Later, if changes occur or problems arise, the team can put that part on hold in the ERP system, triggering a change order. Simultaneously, Vault enables the design and production teams to carefully track revisions to existing designs.

“We make leading-edge technology, so we are developing and revising our products at a fairly high rate,” Kolenosky says. “It is critical to know which vehicles have what revision, as well as which revision of each part is on our shelf, and which revision we want to manufacture. We have to manage this on a daily basis, and Vault helps us do that accurately.”

Vault has also given Rokion a viable way to get rid of paper entirely throughout the design, engineering, and production workflow, because the software makes it easy to control which teams are viewing which data. “Vault is just as important to us as Inventor,” Sakundiak says. “Being able to manage our items and all the files related to each item is extremely valuable.”

Extracting more value from versatile tools

With a solid design and engineering workflow in place, Rokion plans to continue separating itself from the competition and making the most of its Autodesk tools—starting with automating the drawing process.

“We want to automate elements of the process, so engineers and technicians spend less time creating the drawings necessary for fabrication,” says Mike Thomas, technical services manager for machines at Rokion. “It ties into what we’re doing with Vault for managing revisions. The idea is a part catalog that allows our customers to identify what replacement parts they want to order.”

Making life easier for customers may also involve more customer-facing reporting based on the data that the vehicles record while charging or operating. Ideally, Rokion would be able to use the data to help customers do more vehicle self-service with pinpoint accuracy—down to knowing which bolts need to be tightened. All of this depends on keeping reliable data about all of the parts on every vehicle in service.

Finally, the Rokion team is exploring how to leverage finite element analysis (FEA) tools within Inventor to do stress analysis on various vehicle parts. This includes analyzing fatigue loads on fabricated metal components like suspension or frame pieces.

“I started using the stress analysis environment in Inventor for one of the components we’re developing,” Cote says. “FEA used to be a very manual process, but the tools in Inventor did a good job dealing with welded surfaces and contact elements. We’re going to do a lot more of that.”

Get started with the collection

The Product Design & Manufacturing Collection is an integrated set of professional-grade applications that connect everyone, from concept through production, with shared tools to streamline your product development process. The collection enables you to create your most ambitious ideas, collaborate efficiently, automate busywork, and explore more design options than ever before.