Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

Drastically saving time by generating custom stair systems with iLogic automation technology

Viewrail, a leading manufacturer of quality stair parts and custom staircase systems, is rapidly adapting their engineering processes to fulfill custom orders and meet an increase in demand. iLogic in Inventor helped them modernize their process and expedite production of their stair systems for clients looking for custom building products.

By incorporating design automation into their engineering process, Viewrail went from completing an average of 3 engineer-to-order stair systems a week to 150 projects a month.

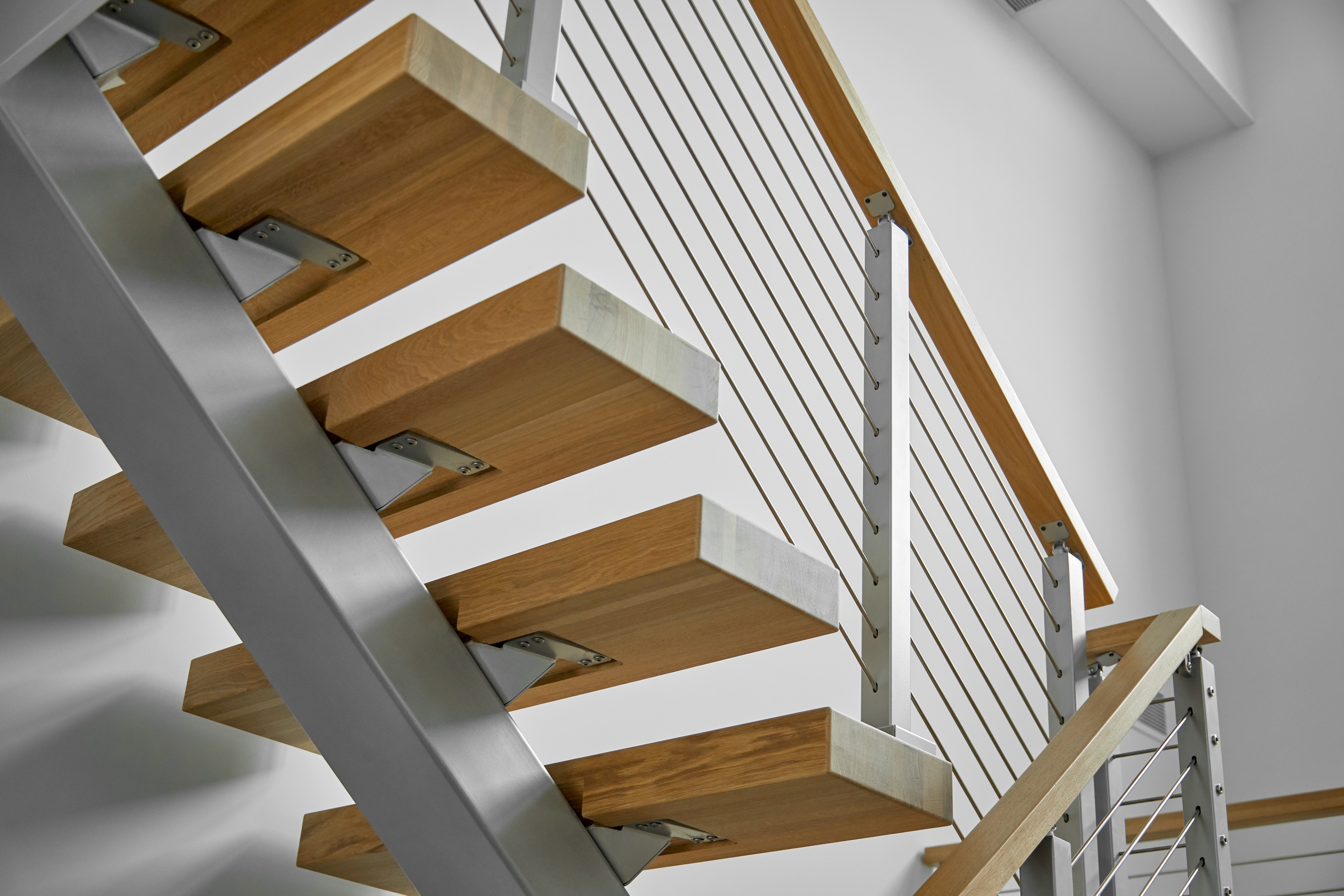

Enriching buildings with thoughtful stair creations

Based in Goshen, Indiana, Viewrail began as a traditional producer of wood stair and railing products. As demand in their industry shifted over time, they extended their production into metal and glass. Currently, their operation has the manufacturing capability to produce thousands of stairway designs and styles for customers around the globe.

But expanding an already impressive portfolio is no easy feat, and doing so at a pace that keeps you well ahead of competitors proves even more difficult–and requires a qualified team to lead. For Viewrail, that team began with JJ Johnson (Chief Operating Officer) and Ryan Rittenhouse (Engineering - Automation Specialist).

The team behind the stair generator: JJ Johnson and Ryan Rittenhouse. Courtesy of Viewrail.

Joining Viewrail from the same company that designed 3D printers, Johnson and Rittenhouse started new roles in Research & Development on the same day, two years ago. Johnson, with a background in engineering education, and Rittenhouse, with a background in programming, were well-positioned to be the dream team that could help Viewrail modernize their custom order process.

Little did they know, three weeks into their start they would begin a project that, over the course of just two years, has helped to manage an estimated 50% increased growth of the business, year over year.

Overcoming challenges in meeting demand

When it comes to designing stair systems for a building, there are always details that vary from one set of stairs to the next. A miscalculation of one measurement can jeopardize the integrity of the entire system. Because of this, one hundred percent of Viewrail’ floating stair system business is engineered to order, with custom measurements, every time.

Before Johnson and Rittenhouse joined, every order that came in was carefully–and manually–drawn by a one-person engineering team. This process of making calculations and drawing in 2D was helped along with basic scripts, but it still took three to four hours to complete a single, simple stair system. Frequently, systems with switchbacks or other added complexity would take multiple days to produce.

Viewrail differs from their industry peers in that they engineer to order remotely, opposed to spending weeks on a job site building a unique system. A particular challenge with this method is ensuring the data they receive from customers is accurate. Even if a model is drawn perfectly the first time, there is still the possibility that a customer will provide updated measurements and they need to start from the beginning again.

Viewrail quickly realized that their floating stairs were gaining in popularity, and demand was projected to outpace the engineering services available to produce them. In order to meet this demand, they either needed to hire a lot more engineers (which would greatly impact their bottom line) or they needed to speed up the engineering process. Fueled by their combined expertise in CAD and code, Johnson and Rittenhouse chose the latter.

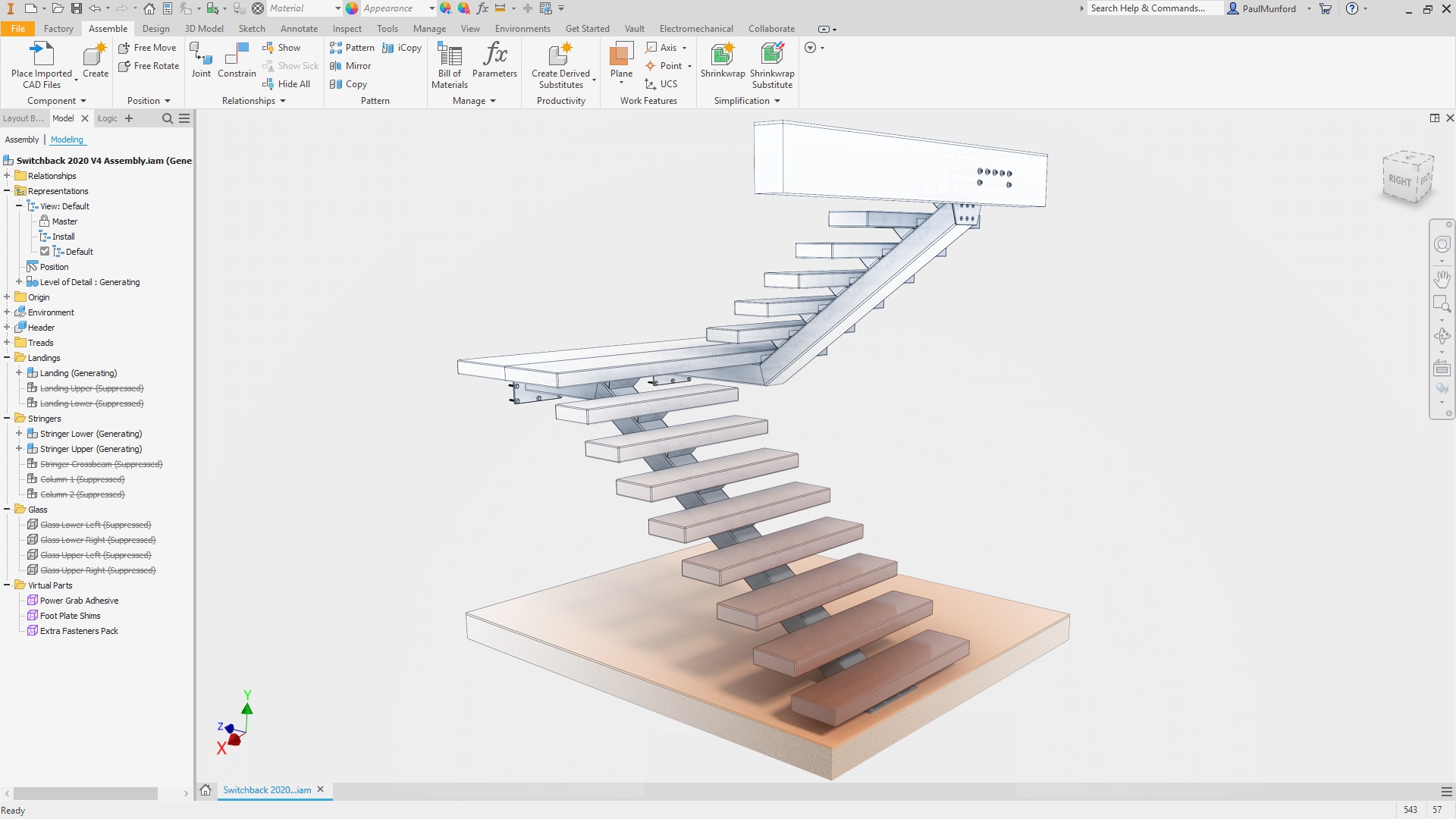

Using iLogic to power a custom stair generator

Johnson and Rittenhouse knew they needed to build something that could automate the process for modeling their stair systems (what would soon become their stair generator), and they immediately began researching the tools available to them. Although Rittenhouse had limited experience in CAD software, he soon discovered what appeared to be a viable option–iLogic technology in Inventor.

“Len Morris, (company owner) provided the vision for where we needed our engineering department to evolve to, we were just kind of the movers and shakers of ‘build this prototype and let's stress it out and see what happens,’” says Johnson.

Under a strict deadline, they set to work building their first stair generator, with Johnson doing the CAD modeling and Rittenhouse writing code in iLogic. “We got it to more or less work for a really simple stairway. Like, ‘Hey, we’re going to go up here, we don’t need to tie into anything. Simple,” says Rittenhouse. “And then almost immediately it’s ‘Oh, we needed to do this, and we need to check for code compliance, and we need to do that. Oh, and that and this,’” he continues.

Johnson and Rittenhouse continued to iterate in iLogic, expanding on its capabilities as they encountered new considerations in their models. “So we started pushing on that and now we're at the point where, in a couple of minutes, you can put in the numbers, hit the button, and the stair generator will pull all of our parts, switch them over to whatever it needs to be based on the types of system the customer has requested, which way the stairs go and any additional design considerations, if it's stainless steel, if it's exterior, etc.,” says Rittenhouse.

“It will figure all of this stuff out and throw it together complete with production drawings, customer prints and lately, our machine code for generating some of the stuff for physically manufacturing it,” he continues.

When we stumbled upon iLogic for this project, the capabilities and the functionality there, there's so much power behind that and we just really fell in love with the abilities that it provides. And now every time we start something, the first thought is, ‘how am I going to make this a smart design so that I can apply iLogic to it later on if I need to?

—JJ Johnson, Chief Operating Officer, Viewrail

Moving from 2D to 3D

Rittenhouse and Johnson chose iLogic technology over other automation options available to them because of the additional benefits that come with modeling in 3D. When designed in Inventor, they can physically double-check their models, and this gives them the reassurance they need to confidently move swiftly from ordering to production.

“Now we're pushing everything into 3D. The guy drawing glass can open one of these generators and draw the glass right on the stair system...It gives our engineers a framework to play with. And since it's drawn right on top of what we're manufacturing out of, it will be perfect. It will line up when it gets to the customer's house,” shares Rittenhouse.

Skyrocketing business with a modern approach

By powering their stair generator with automation capabilities in Inventor, Viewrail reached impressive milestones.

- iLogic automation cut stair system design time from 4 hours to 2 minutes (a decrease of 12,000%)

- Stair generator increased number of completed monthly orders from 12 to 150 (an increase of 1,250%)

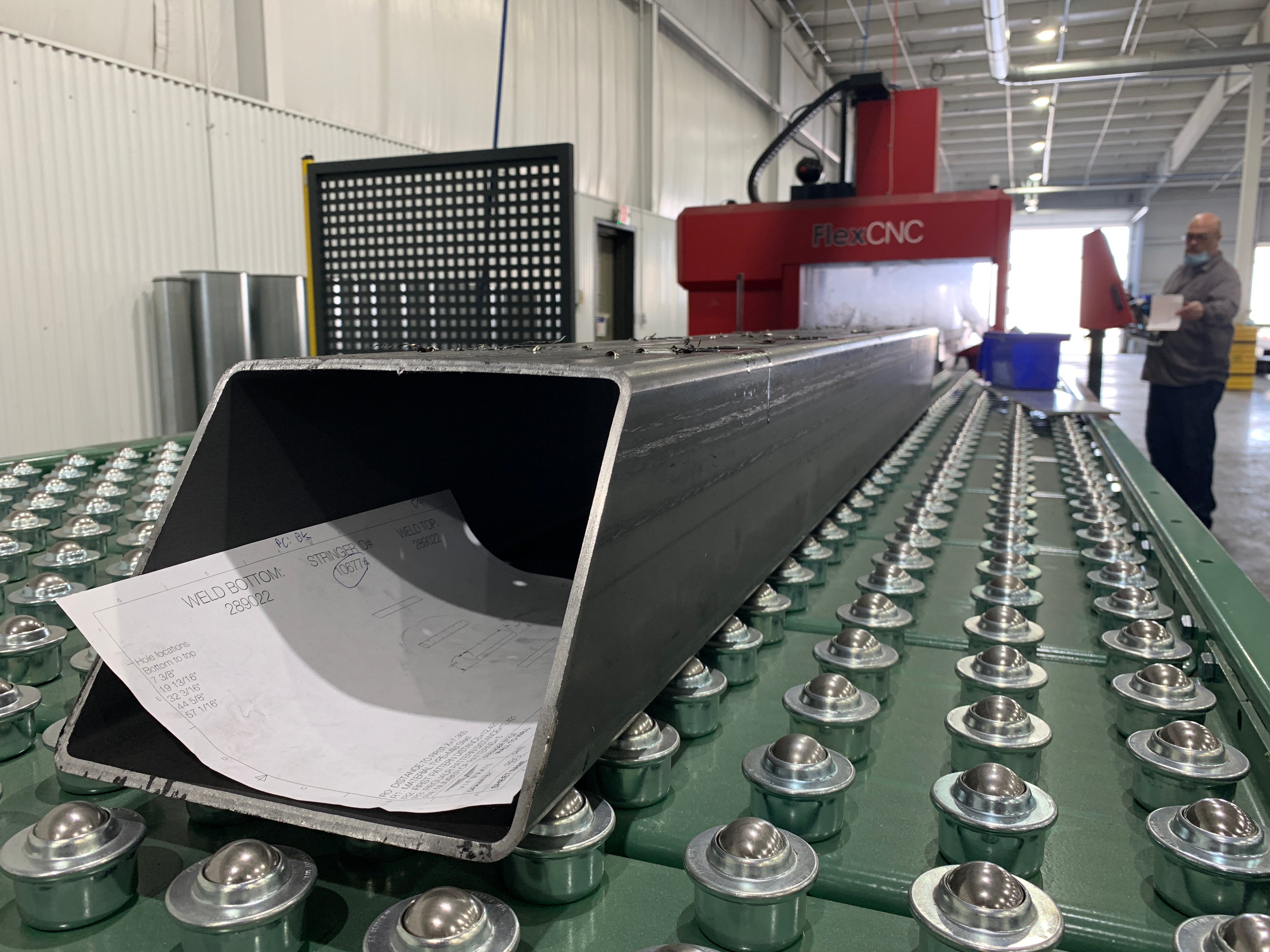

A complete assembly of central beam, wooden components, and sheet metal brackets. Courtesy of Viewrail.

What started as a small task force has expanded into a team that is 21 strong, and now Johnson manages a group that encompasses research and development, engineering, automation, and product development. The stair generator has completely transformed their process and has made room for them to innovate on their product offerings.

“Our goal is always to have the constraint be on our sales team. Because if we can turn them up and everything else can handle it down the line, that's great...It seems like every time we get really solid on a generator, they want to stretch the rules in sales, and the customer wants to stretch the rules. And they want to do something really exotic. Just yesterday, we processed two jobs that they want 12-foot-wide landings. And for a stair system, that's really, really wide,” says Johnson.

“We’re such a fast-growing company, we have to be quick in response; agility and response to our market's desires are very important," he concludes.

Get started with automation

Automation tools offered in the Product Design & Manufacturing Collection are designed to be a scalable solution that matures as you reach your goals. Products in the collection can help to define rules that drive custom product configurators, drawing creation, toolpaths, simulation setup, and more.