AutoCAD

AutoCAD AutoCAD LT

AutoCAD LT Fusion

Fusion AutoCAD Revit LT Suite

AutoCAD Revit LT Suite Architecture, Engineering & Construction Collection

Architecture, Engineering & Construction Collection Revit

Revit Civil 3D

Civil 3D BIM Collaborate Pro

BIM Collaborate Pro Product Design & Manufacturing Collection

Product Design & Manufacturing Collection Maya

Maya Inventor

Inventor Navisworks

Navisworks 3DS Max

3DS Max Fusion Extensions

Fusion ExtensionsMaximize your capabilities

From printing, to milling, to molding. Across additive, subtractive, generative and simulation. Autodesk offers software to help OEMs and automotive suppliers design and manufacture component parts, and the molds, tools and dies that go into making them.

Manufacturing in the automotive industry is complex and continues to evolve. Driven by data, connectivity, and new modes of working, the need for advanced manufacturing is expanding.

Automotive manufacturing is the process of converting materials into components that are used to create vehicles. Digitization and automation have emerged as the leading technologies to raise efficiency and build competitive advantage.

Automotive manufacturing software is used to machine, print, inspect, simulate, and fabricate parts. The software will virtually simulate the manufacturing processes and then control the machines for the actual fabrication process.

Social, political, and environmental pressures are redefining the automotive sector. Electrification, mass customization, robotics, automation, and additive manufacturing are changing the cars we want and the processes that are used to make them.

Navigate to the interactive experience using the categories below to easily find the information that is most relevant to you.

Learn about the biggest trends affecting the automotive parts manufacturing supply chain.

See how successful manufacturers are embracing technology to overcome their biggest challenges.

Access personalized learning content designed for engineers, managers, and senior executives.

Learn more about streamlining manufacturing workflows to improve process efficiency, embrace automation, and reduce costs.

Learn how automation tools can help manufacturers shorten delivery times and enable parts to be delivered to the supply chain on time.

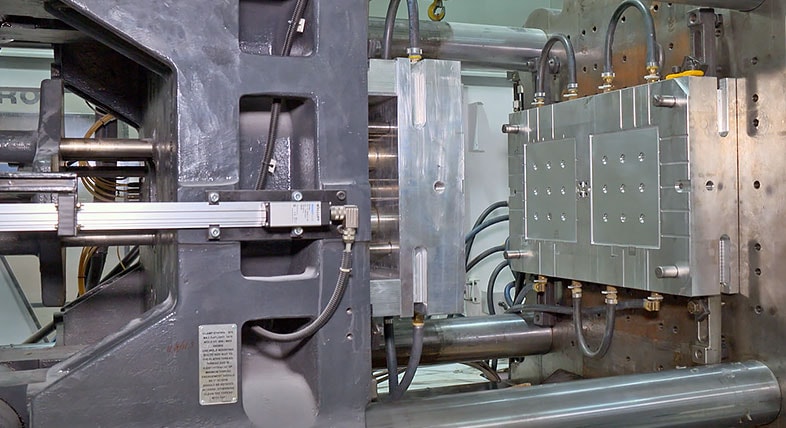

Simulation plays a central role in validating and optimizing mold designs to ensure they're fit for purpose and ready for CNC machining.

Combine high-rate additive and subtractive processes to enable the rapid production of lighter, more energy efficient components.

See how our digital manufacturing toolset can help lead you to an agile manufacturing process, enabling delivery on Industry 4.0.

Staying competitive is no longer just a matter of having the latest hardware in your shop, you need software and plant solutions to bring advanced manufacturing technology to its full potential and stay ahead of the curve.

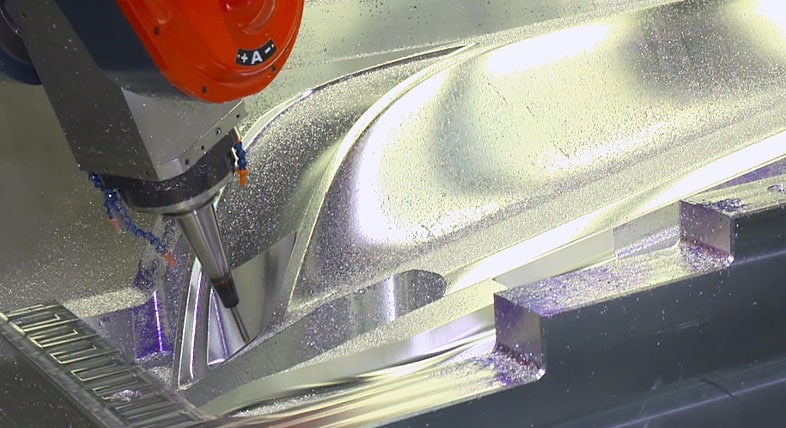

Use CAM software to rapidly produce safe and efficient 2-, 3-, and 5-axis machining NC code. Drive CNC machine tools, multitasking centers, and wire EDMs.

Combine the versatility of high-rate, additive manufacturing with the precision of CNC machining to produce new components or repair damaged molds and tools.

Rapidly convert digital concepts into physical prototypes. Use customizable templates to automate the inspection, marking out, and milling of entire vehicles or local sections.

Discover how industrial robots can automate manufacturing processes such as polishing and trimming of metals and composites, releasing workers to focus on higher value tasks.

Control quality and repeatability of manufacturing processes. Use in-cycle inspection to identify non-conformance, answer critical questions, and improve productivity.

Automate your workflow from design to NC code. Reduce programming time, and produce consistent results for CNC milling, turning, and wire applications.

Simulate manufacturing processes and plastic injection molding to improve plastic part and mold designs.

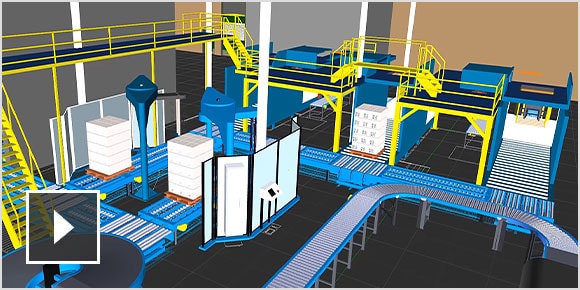

Visualize and optimize your factory designs for efficient equipment placement to improve production performance.

Simultaneously generate multiple CAD-ready solutions based on real-world manufacturing constraints and product performance requirements.

Optimize the manufacturing process of composites by designing, analyzing, and manufacturing with one integrated solution.

In this eBook, learn about the major challenges facing the automotive sector today and how emerging technologies such as hybrid manufacturing, simulation, and automation are helping to bring the next generation of vehicles to market faster.

General motors

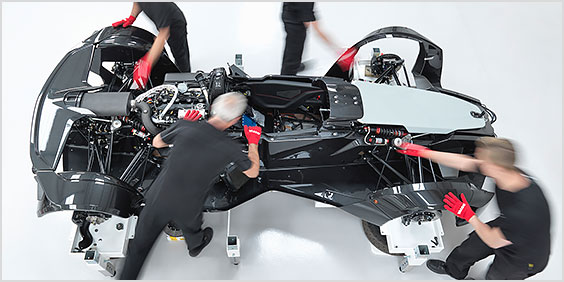

Global automaker takes a big leap forward in automotive design and manufacture to imagine a future of lighter, more efficient, and customizable cars. Using generative design, artificial intelligence and additive manufacturing, the company can affordably and efficiently make components that deliver better performance and more options to customers.

Image courtesy of General Motors

Paragon D&E

Large mold and die company invests in Autodesk CAM software to replace 5 different systems, improving part quality, and reducing turnaround times by 50%.

3-Dimensional services group

Rapid manufacturing services provider reduces errors by delivering consistent information across the company—from the design stage to the shop floor.

Call us toll-free or complete this form to speak with us about our full portfolio of automotive manufacturing solutions.

Call 1-855-612-9998 (toll-free in US)

Lines open Monday through Friday, 9am to 5pm.

Learn about the future of car design and how virtual reality (VR), generative design, and real-time clay modeling work together to enhance the design process.