Quickly import your designs with the largest set of CAD data translators for 50+ different file types. Directly edit existing features or model fixtures with a truly integrated CAD / CAM platform.

FUSION 360 FOR MACHINISTS

Manufacturing has changed.

So should your tools.

Make quality parts, faster. Reduce cycle times and increase your bottom line utilising a single unified platform.

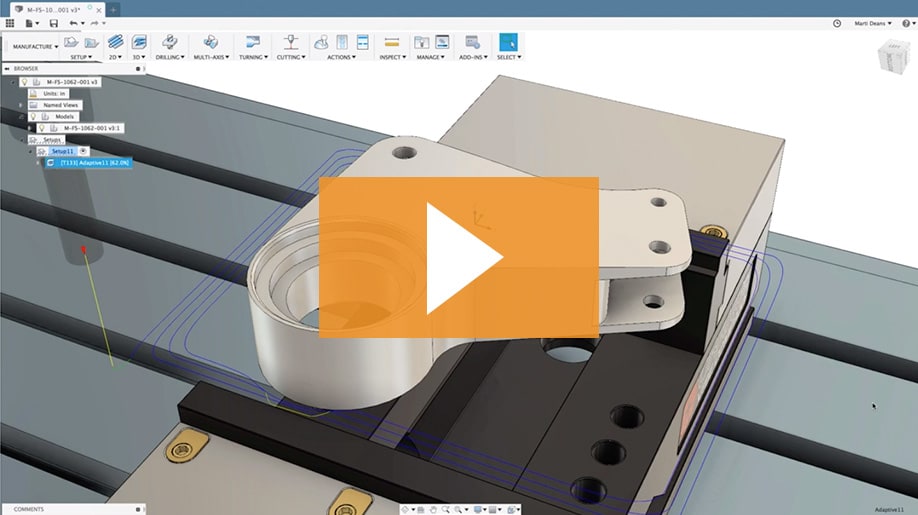

Go from design to machining faster

Generate toolpaths in minutes, not hours

Effortless setup and programing allows you to make parts faster. Post full NC programs with a post from our extensive library of free, open source, and fully editable processors.

Get CAD + CAM at a fraction of the cost

Stretch your budget further by eliminating costly, disparate CAD / CAM tools with one affordable integrated solution.

Start making today

Reduce your time to market by 60% with one CAD / CAM solution.

Cut costs in half by reducing cycle times and unnecessary man hours.

Create toolpaths twice as quickly and start machining faster

- Overview

- Machining Extension

- 2.5 & 3-axis Milling

- 3+2 Milling (5-axis Positional)

- 4-axis Milling

- 5-axis Simultaneous Milling

- Setup Probing

- Turning

- Mill-Turning

- Water Jet, Laser Cutter, Plasma Cutter

- Free Post Processor Library

Manufacturing

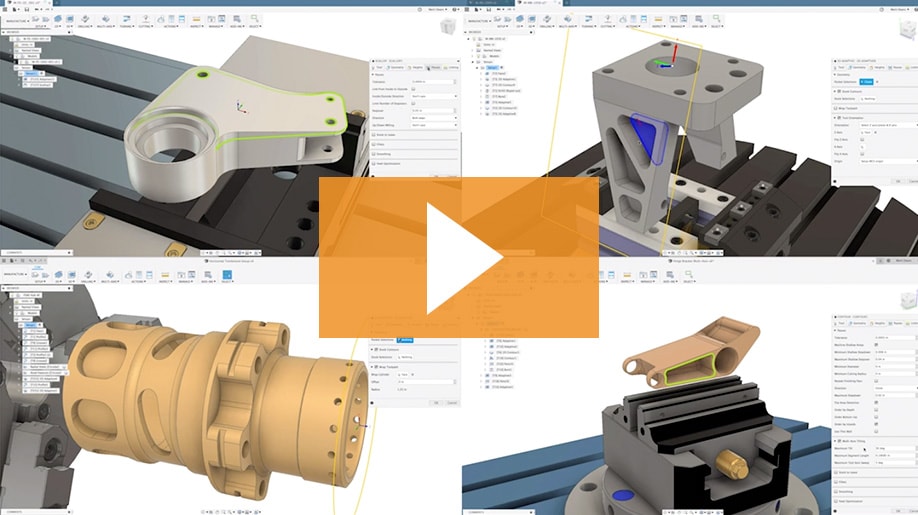

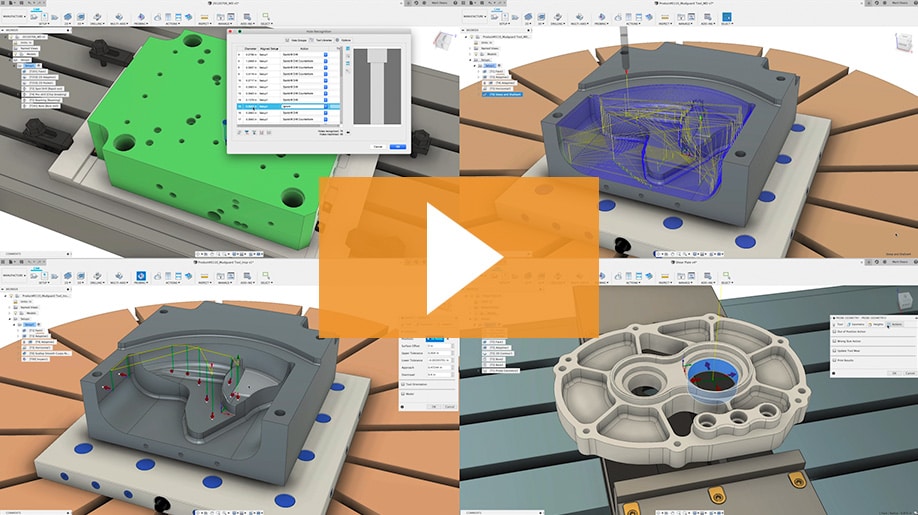

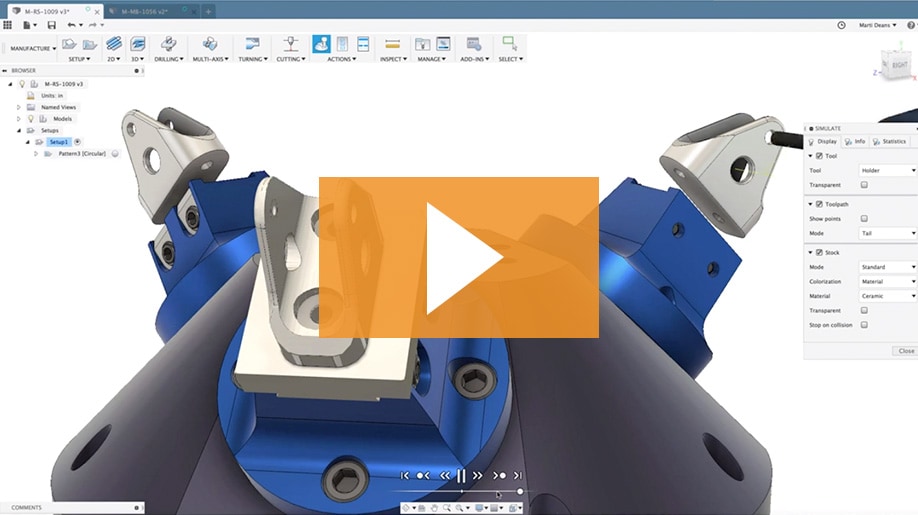

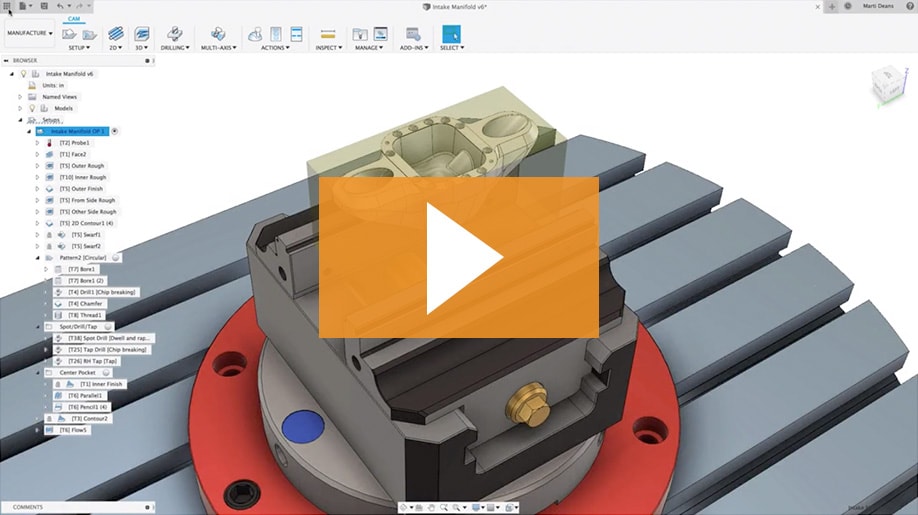

From high-efficiency roughing with Adaptive Clearing to simplified control of multi-axis machines with Tool Orientation, Fusion 360 makes it easy to program your CNC machine, fast. Manufacture with 2.5, 3, 4, and 5-axis milling, probing, turning, mill-turning, and profiling operations paired with a powerful post engine all included alongside professional design tools.

Machining Extension

Extend the CAM capabilities of Fusion 360 with more advanced manufacturing technologies, including 5-axis programming, toolpath optimization, process automation, on-machine verification, and more.

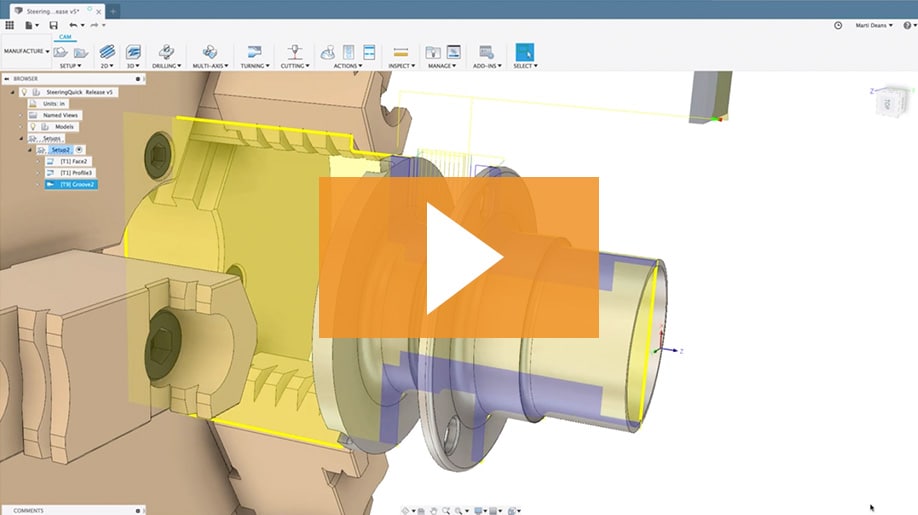

2.5 & 3-axis Milling

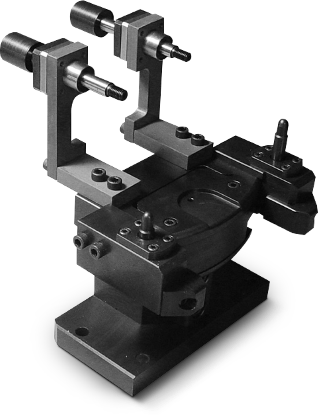

Quickly set up jobs and generate toolpaths to machine quality parts while reducing wear on your tools with fully integrated CAM, including 2.5 and 3-axis operations.

The quality of parts coming off our machines has improved due to more efficient programming strategies, as well as the integrated CAD environment.

- Jonathan Bancroft G2 Crowd

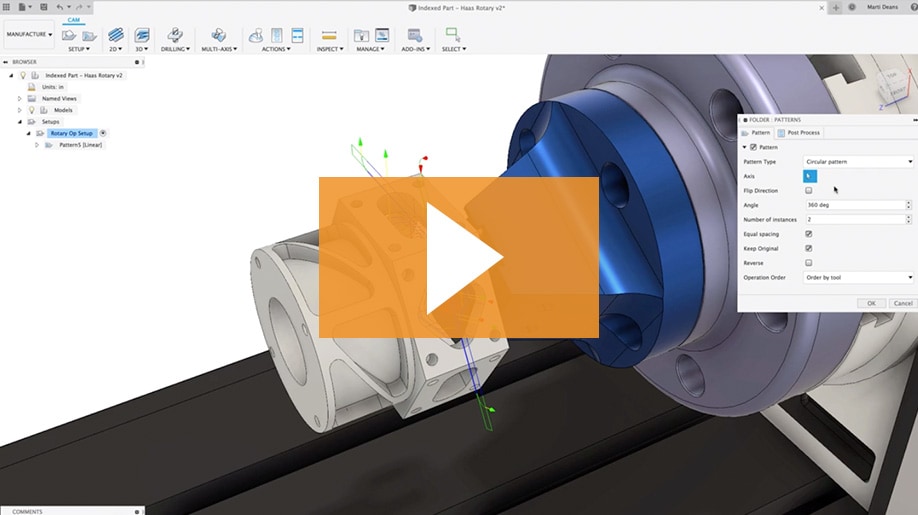

3+2 Milling (5-axis Positional)

Leverage your shop's multi-axis capabilities with straightforward positional 5-axis programming that will significantly reduce machine setup time between operations.

With our other program, it would take an hour to calculate toolpaths. With Fusion 360, just couple of minutes.

- Jeff Hooper Backhand Bikes

4-axis Milling

Create indexed or wrapped toolpaths using the rotary axis of your machine for complex geometry.

I needed the ability to cut path the base of the part to avoid tool charges. This has allowed me to reduce the production time by nearly 80%.

- Dave Killalea

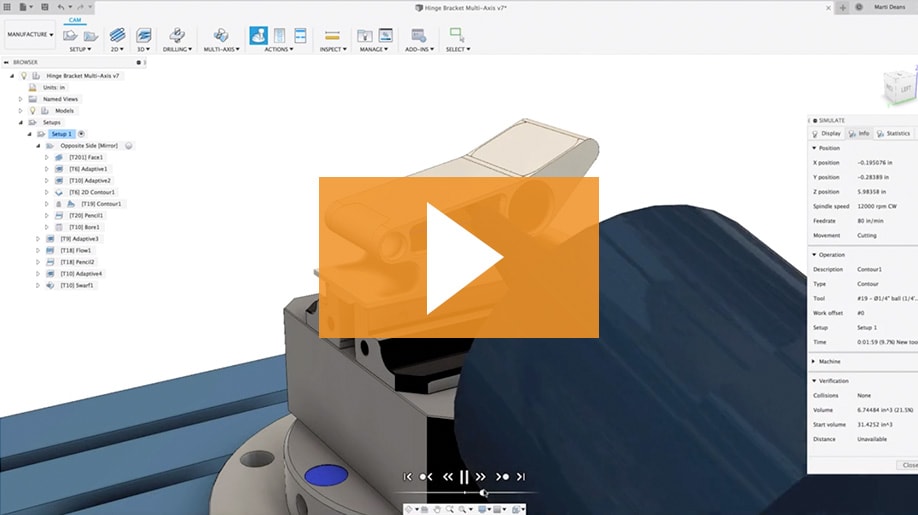

5-axis Simultaneous Milling

Mill complex geometry, avoid collisions, and reduce tool lengths for superior surface finished with simultaneous full 5-axis operations.

I can have something from design stage to off the machine in one hour.

- Phil Butterworth MJK Performance

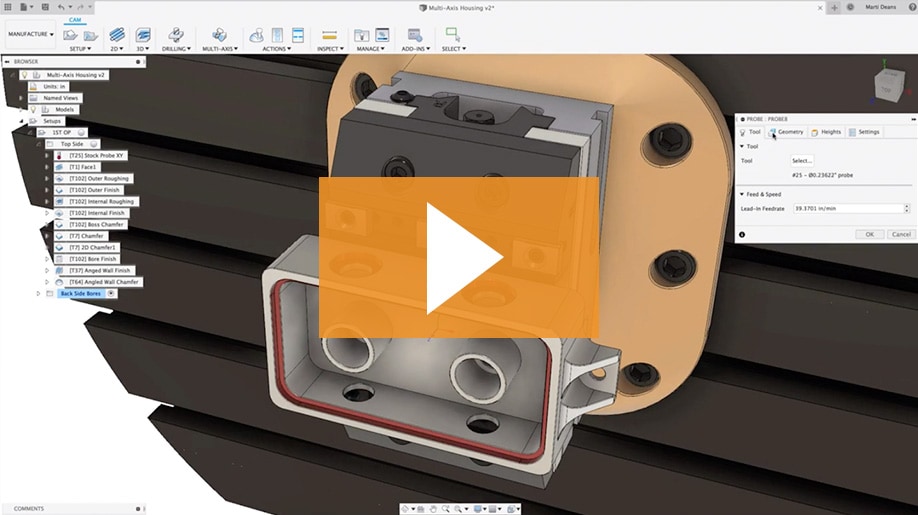

Setup Probing

Leverage in-machine touch probes to shift work offsets and simplify your setup process.

Fusion 360 is our CAM workhorse. It has be able to do everything we have needed so far.

- Administrator Machine Shop

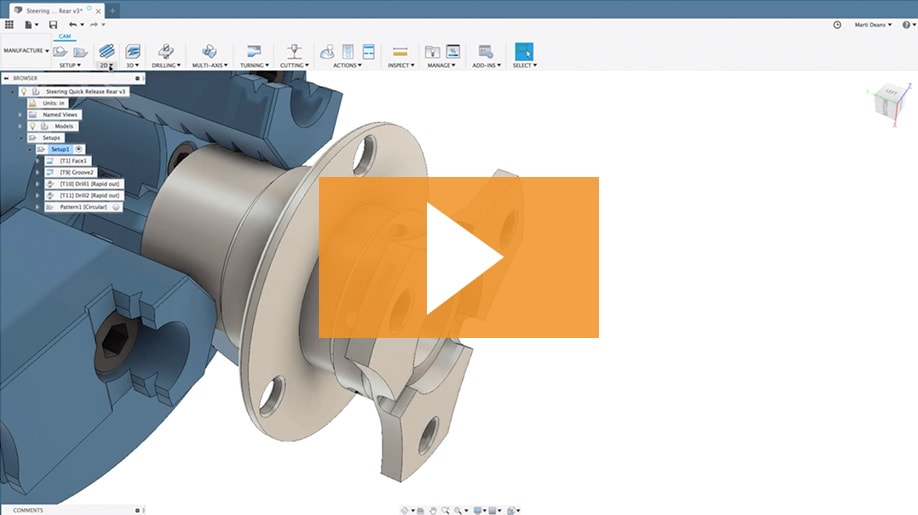

Turning

Program 2d turned parts and verify your turning toolpaths with stock simulation to identify errors or collisions with the model, stock, tools, and workholding.

Fusion 360 is our CAM workhorse. It has be able to do everything we have needed so far.

- Administrator Machine Shop

Mill-Turning

Combine milling and turning operations to create more complex parts without switching machines.

Fusion 360 has reduced our time to market by about 60%.

- KMP Motorsports

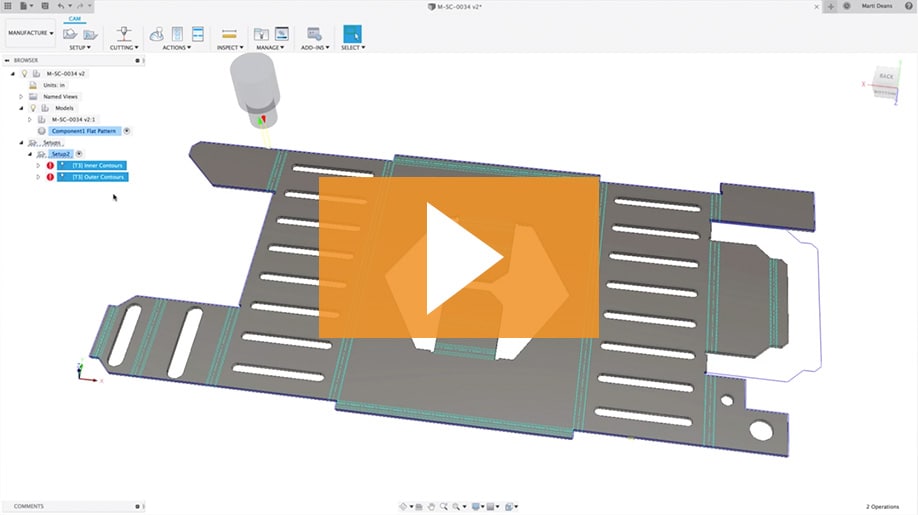

Water Jet, Laser Cutter, Plasma Cutter

Generate toolpaths from solid model features, including flattened sheet metal components, to operate water jet, laser, and plasma cutters.

Full-features CAM and CAD reduced time to make products by over 20%.

- Sean Miksys Great Lakes Machining

Free Post Processsor Library

Post full NC programs in seconds with a post from our extensive library of free, open source, and fully editable post processors.

On our very first project, we saved over $14,000 by reducing cycle time by 9 minutes with no additional tool wear.

- Daniel Colbert Colbert Manufacturing

Extend your capacity

Extend the CAM capabilities of Fusion 360 with more advanced manufacturing technologies, including 5-axis programming, toolpath optimization, process automation, on-machine verification, and more.

Reduce your programming time, make better use of your CNC machinery, and improve the quality and value of your machined parts.

See how MJK Performance is winning with Fusion 360

MJK Performance, a leader in aftermarket motorcycle parts, uses Fusion 360 to design and manufacture precision CNC parts. The integration of CAD and CAM and ease of use has allowed them to exponentially grow their business.

"On our very first project using Fusion 360, we saved over $14,000 by reducing cycle time by 9 minutes with no additional tool wear. That has a direct impact on our bottom line."

Daniel Colbert, Colbert Manufacturing