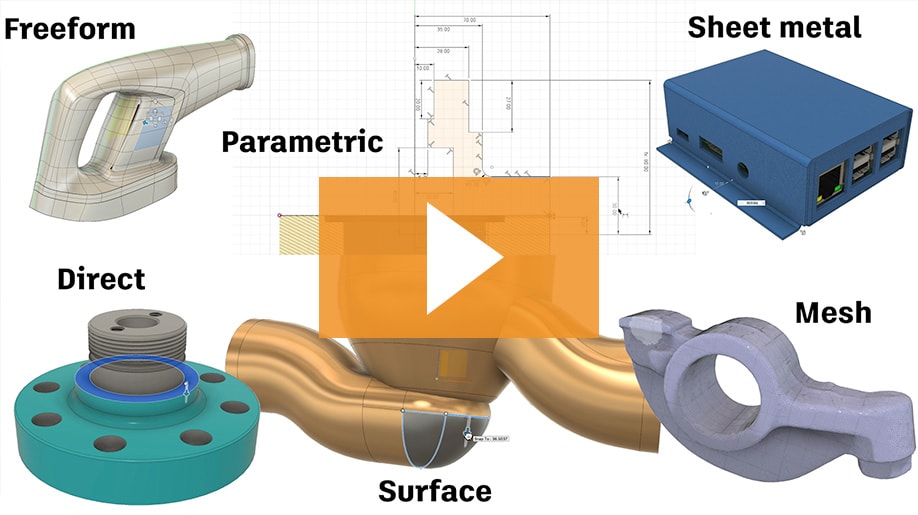

- Overview

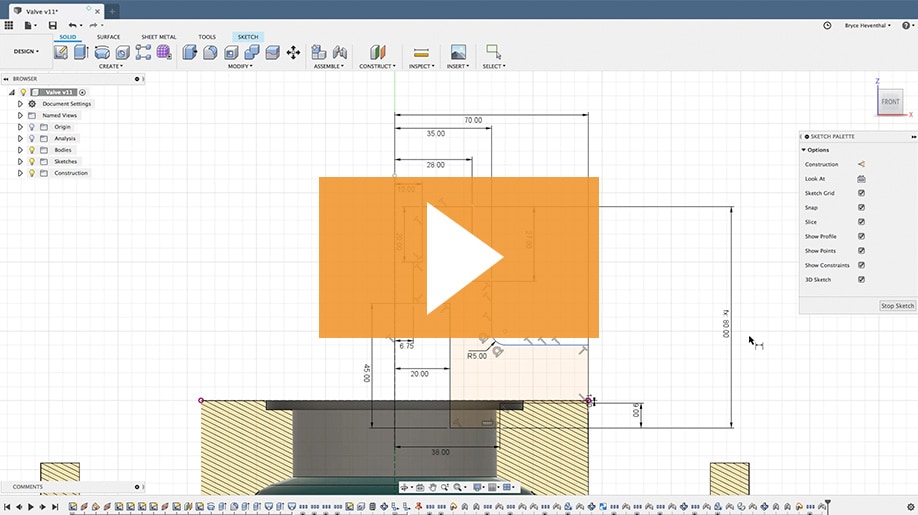

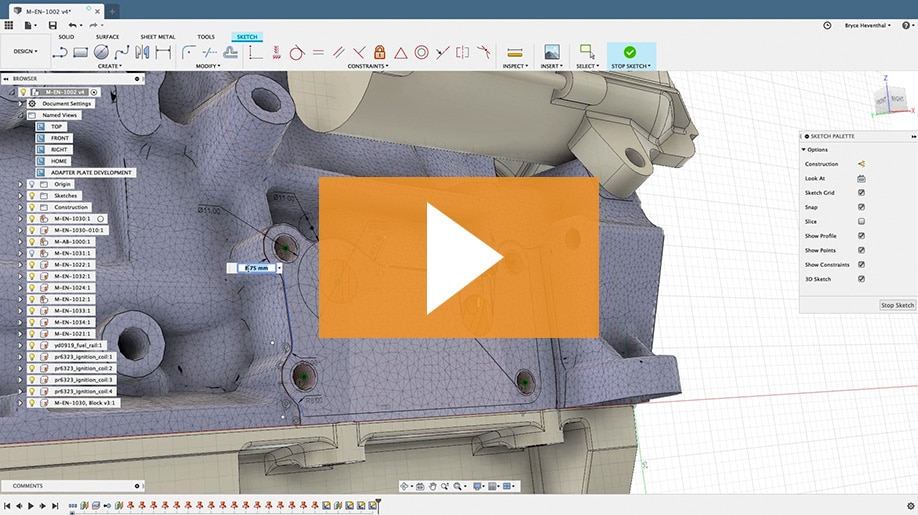

- Sketching

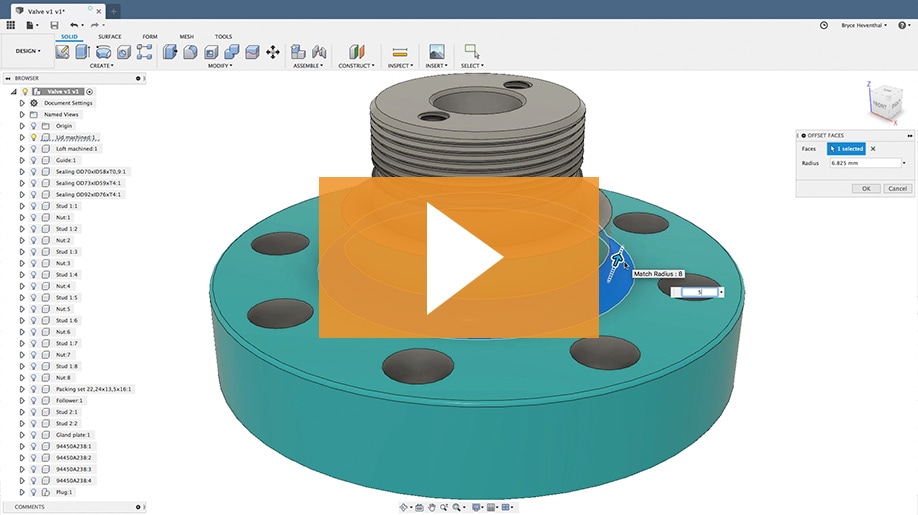

- Direct Modeling

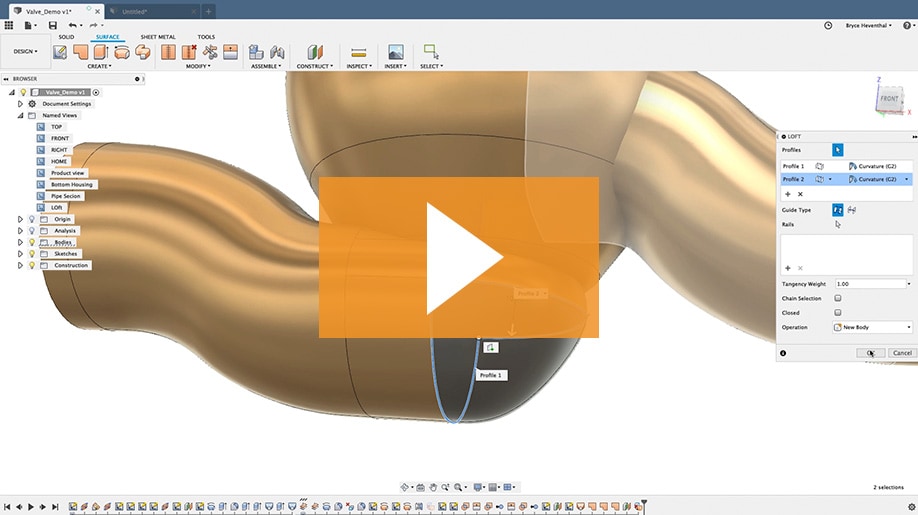

- Surface Modeling

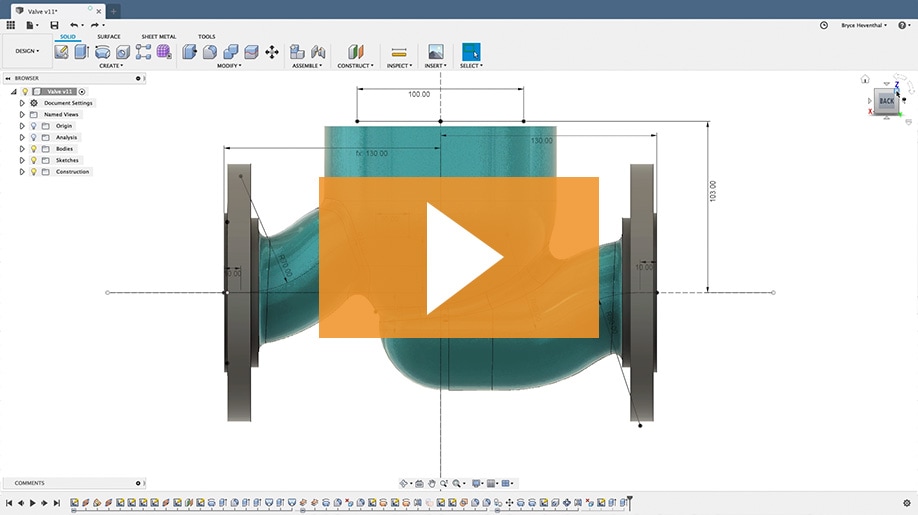

- Parametric Modeling

- Mesh Modeling

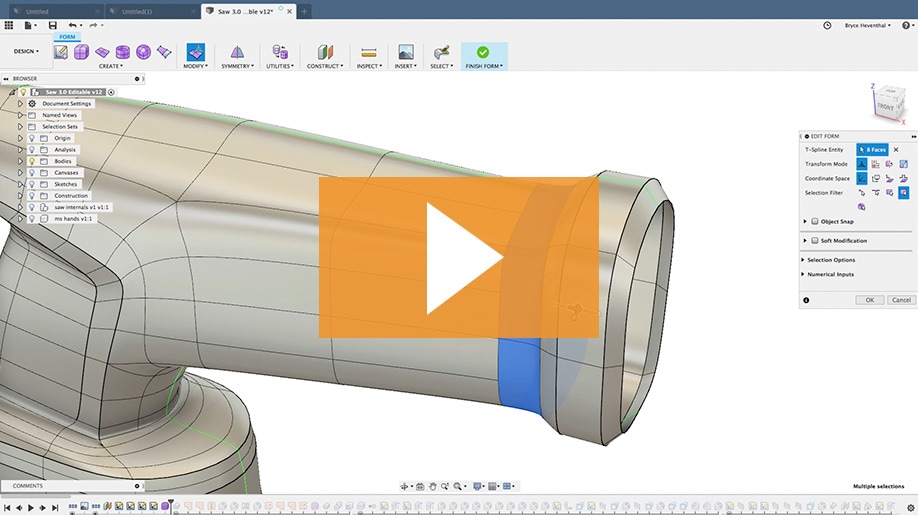

- Freeform Modeling

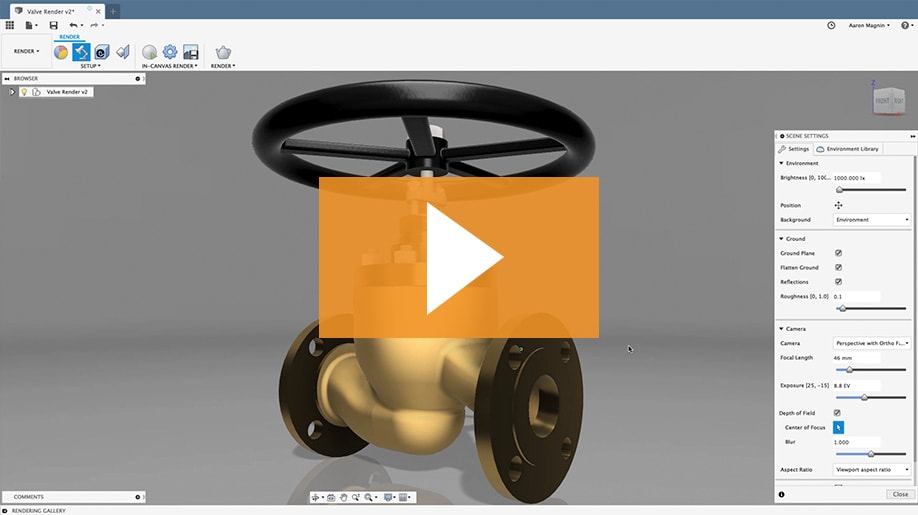

- Rendering

- PCB Design Integration

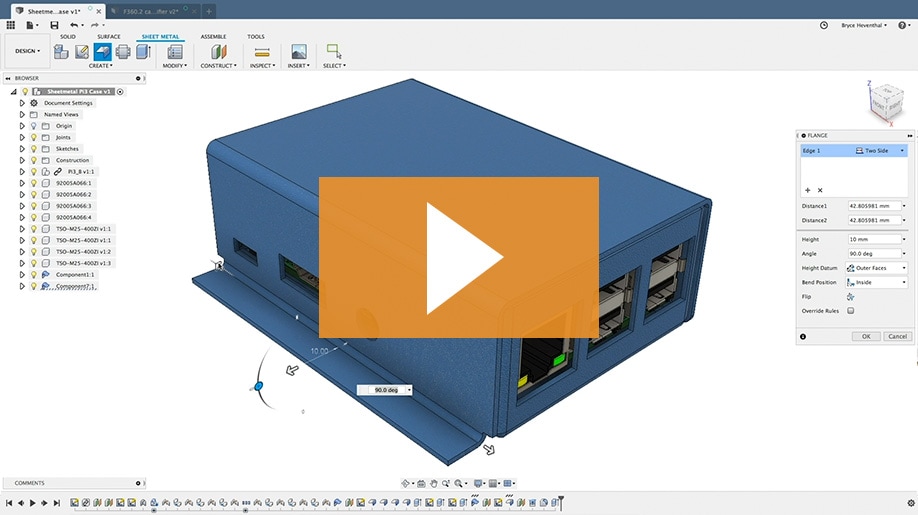

- Sheet Metal

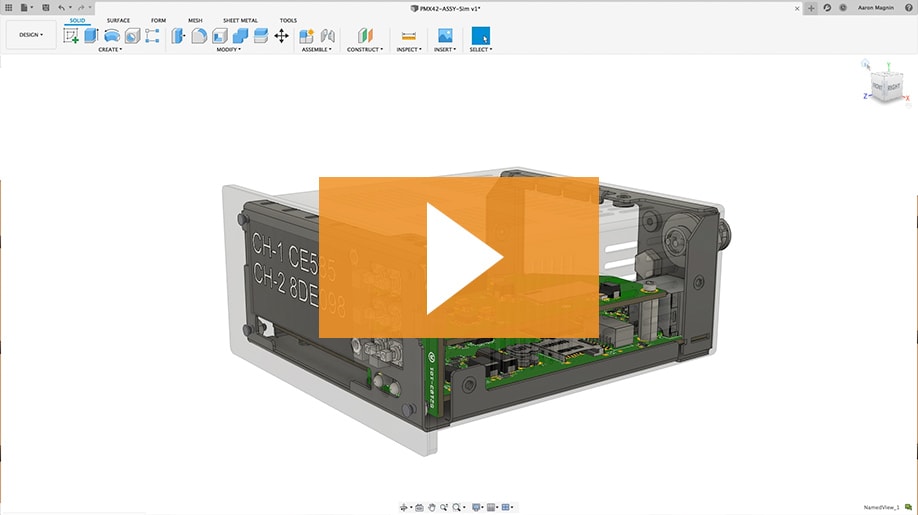

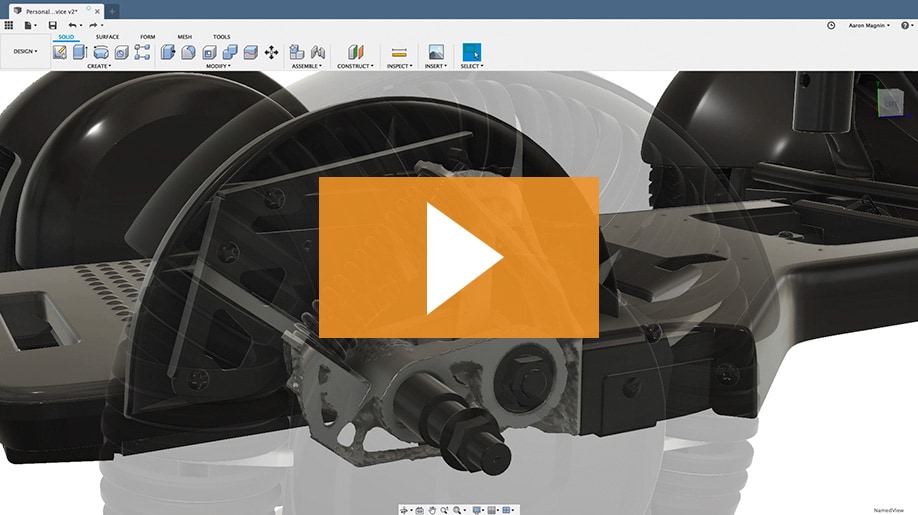

- Assemblies

FUSION 360 FEATURES

One product. Unlimited possibilities.

Bring products to market faster and impact your bottom line through a connected product development process.

- Overview

- Machining Extension

- 2.5 & 3-axis Milling

- 3+2 Milling (5-axis Positional)

- 4-axis Milling

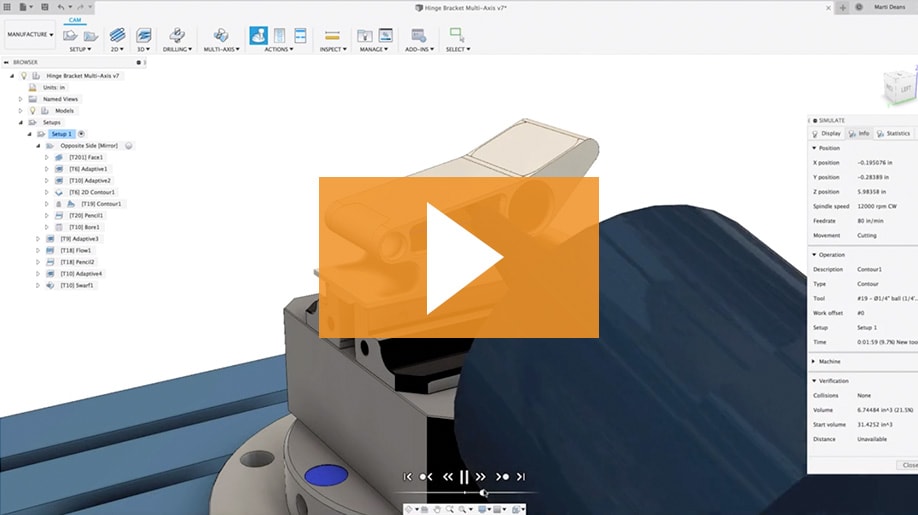

- 5-axis Simultaneous Milling

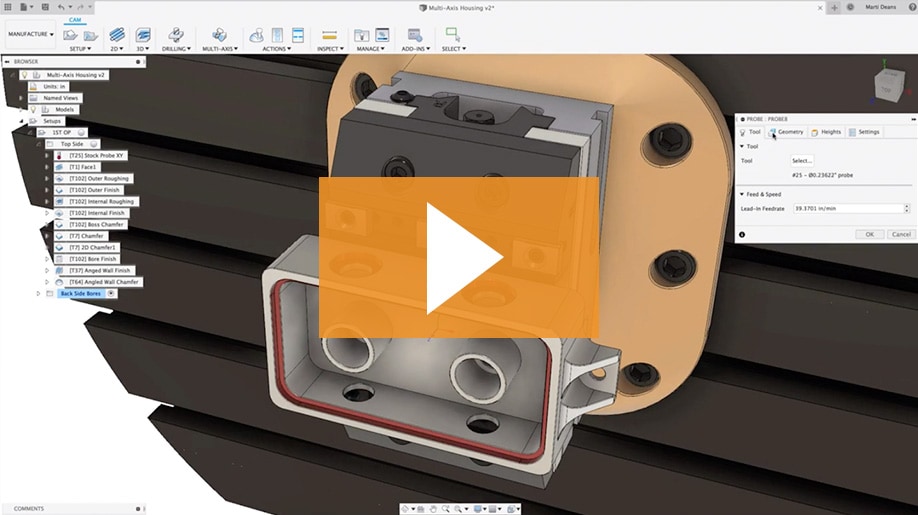

- Setup Probing

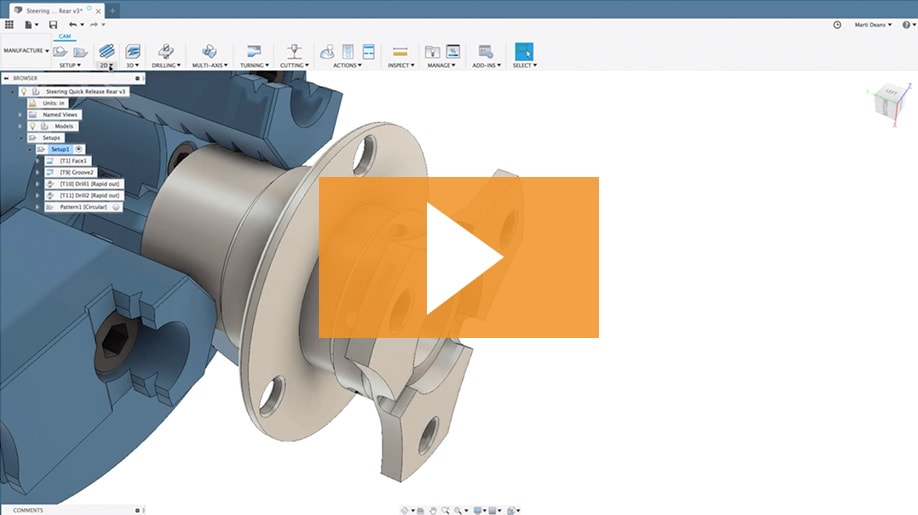

- Turning

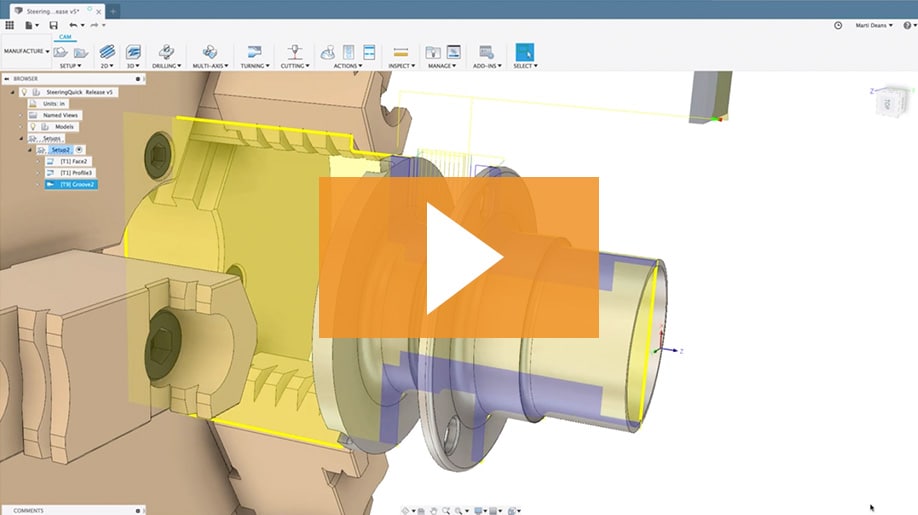

- Mill-Turning

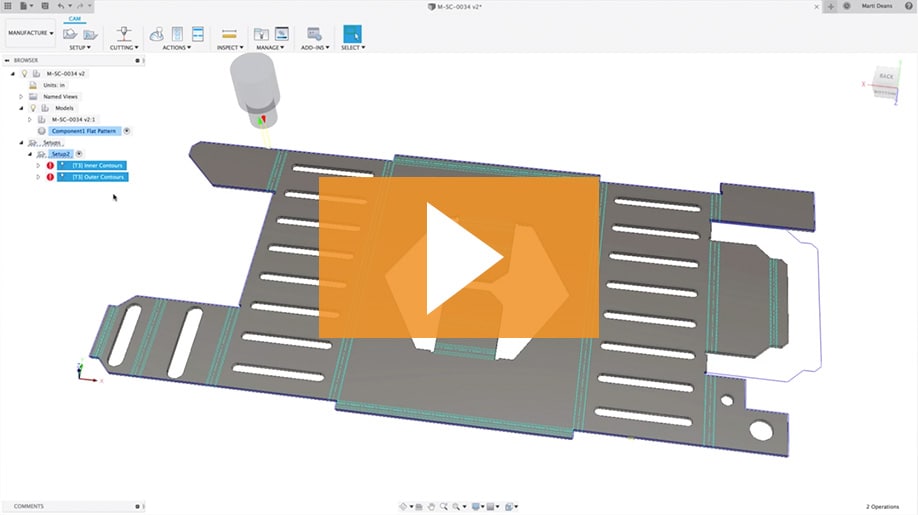

- Water Jet, Laser Cutter, Plasma Cutter

- Free Post Processor Library

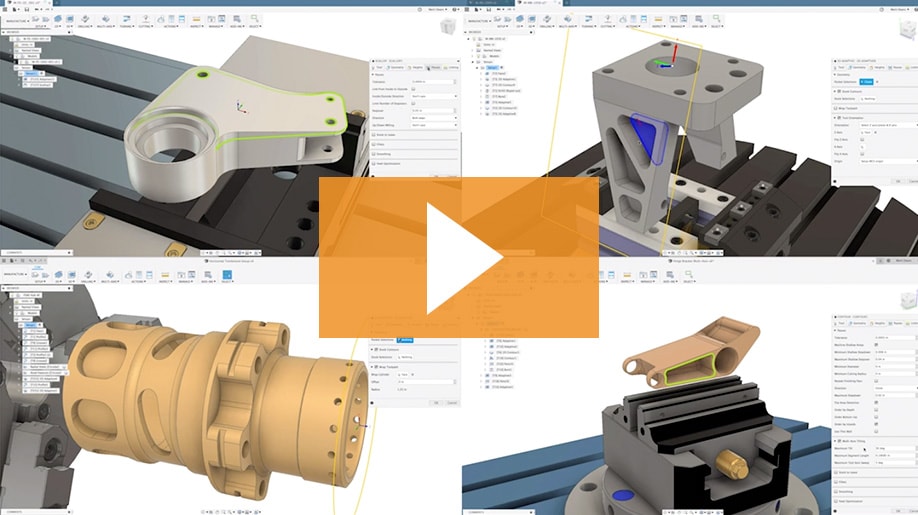

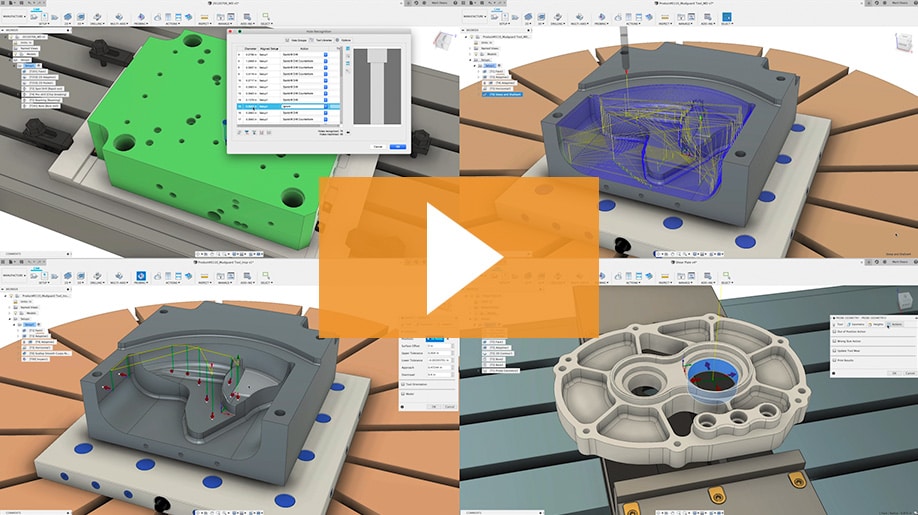

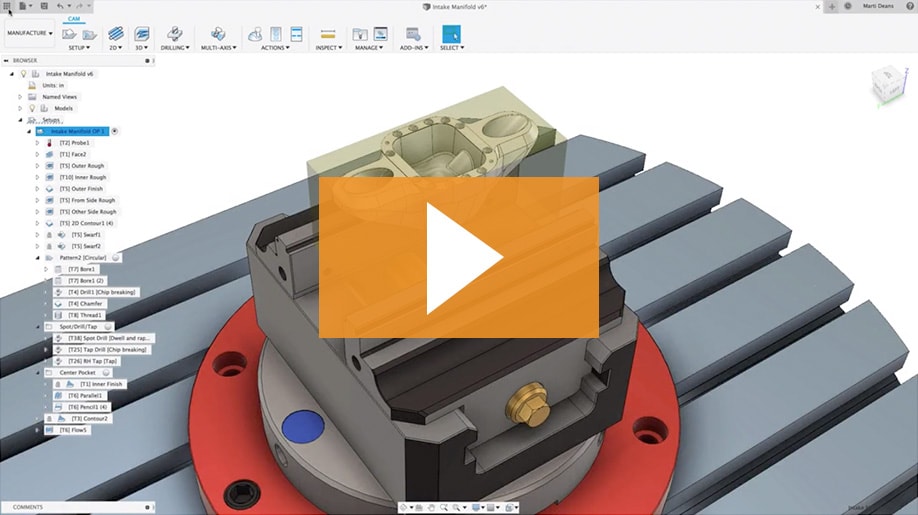

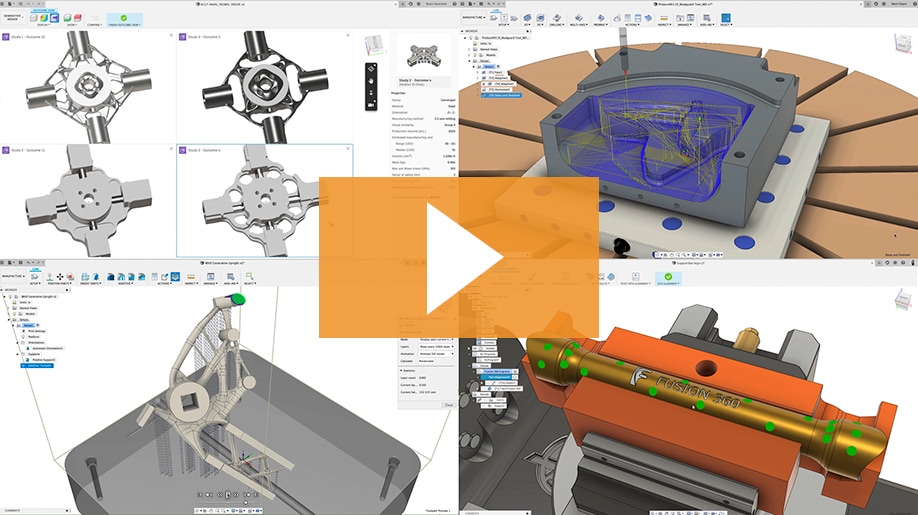

Manufacturing

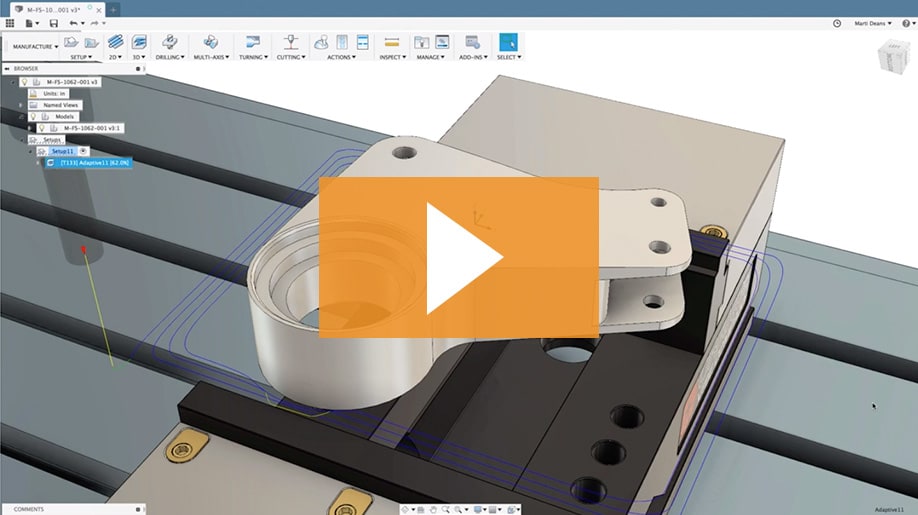

From high-efficiency roughing with Adaptive Clearing to simplified control of multi-axis machines with Tool Orientation, Fusion 360 makes it easy to program your CNC machine, fast. Manufacture with 2.5, 3, 4, and 5-axis milling, probing, turning, mill-turning, and profiling operations paired with a powerful post engine all included alongside professional design tools.

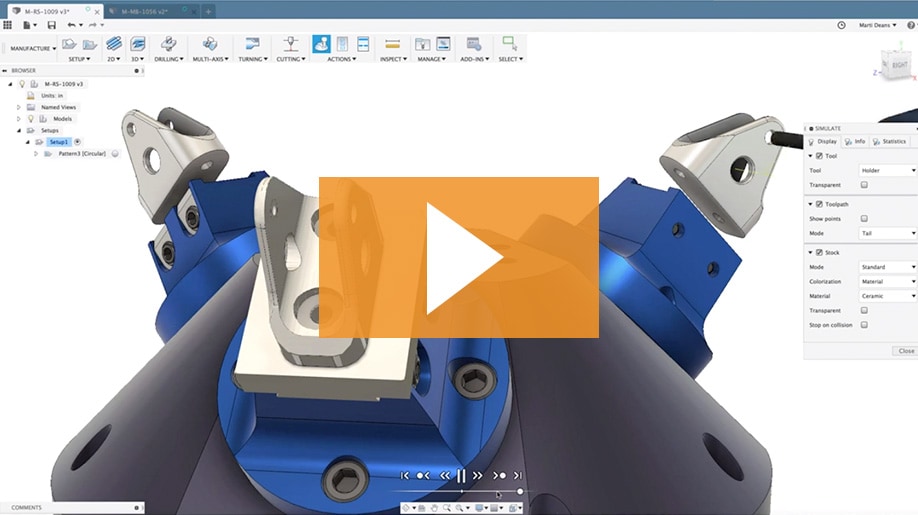

Machining Extension

Extend the CAM capabilities of Fusion 360 with more advanced manufacturing technologies, including 5-axis programming, toolpath optimization, process automation, on-machine verification, and more.

2.5 & 3-axis Milling

Quickly set up jobs and generate toolpaths to machine quality parts while reducing wear on your tools with fully integrated CAM, including 2.5 and 3-axis operations.

The quality of parts coming off our machines has improved due to more efficient programming strategies, as well as the integrated CAD environment.

- Jonathan Bancroft G2 Crowd

3+2 Milling (5-axis Positional)

Leverage your shop's multi-axis capabilities with straightforward positional 5-axis programming that will significantly reduce machine setup time between operations.

With our other program, it would take an hour to calculate toolpaths. With Fusion 360, just couple of minutes.

- Jeff Hooper Backhand Bikes

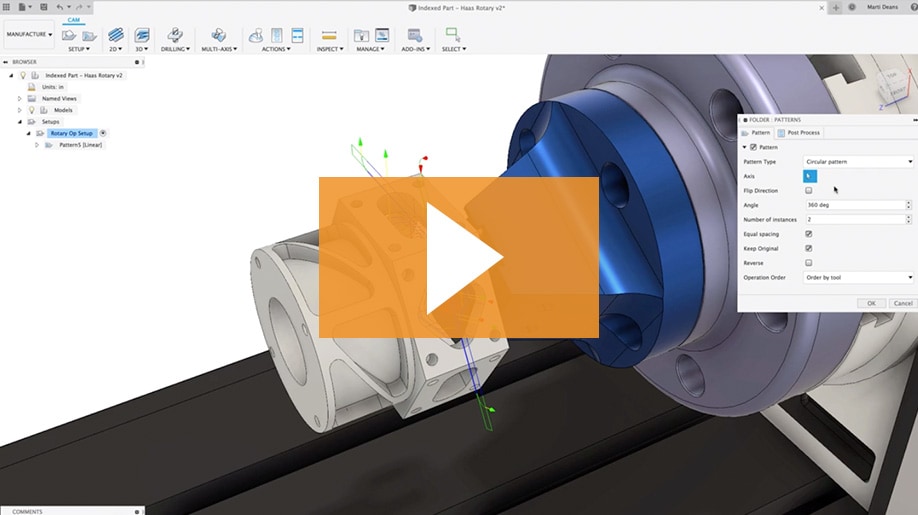

4-axis Milling

Create indexed or wrapped toolpaths using the rotary axis of your machine for complex geometry.

I needed the ability to cut path the base of the part to avoid tool charges. This has allowed me to reduce the production time by nearly 80%.

- Dave Killalea

5-axis Simultaneous Milling

Mill complex geometry, avoid collisions, and reduce tool lengths for superior surface finished with simultaneous full 5-axis operations.

I can have something from design stage to off the machine in one hour.

- Phil Butterworth MJK Performance

Setup Probing

Leverage in-machine touch probes to shift work offsets and simplify your setup process.

Fusion 360 is our CAM workhorse. It has be able to do everything we have needed so far.

- Administrator Machine Shop

Turning

Program 2d turned parts and verify your turning toolpaths with stock simulation to identify errors or collisions with the model, stock, tools, and workholding.

Fusion 360 is our CAM workhorse. It has be able to do everything we have needed so far.

- Administrator Machine Shop

Mill-Turning

Combine milling and turning operations to create more complex parts without switching machines.

Fusion 360 has reduced our time to market by about 60%.

- KMP Motorsports

Water Jet, Laser Cutter, Plasma Cutter

Generate toolpaths from solid model features, including flattened sheet metal components, to operate water jet, laser, and plasma cutters.

Full-features CAM and CAD reduced time to make products by over 20%.

- Sean Miksys Great Lakes Machining

Free Post Processsor Library

Post full NC programs in seconds with a post from our extensive library of free, open source, and fully editable post processors.

On our very first project, we saved over $14,000 by reducing cycle time by 9 minutes with no additional tool wear.

- Daniel Colbert Colbert Manufacturing

- Overview

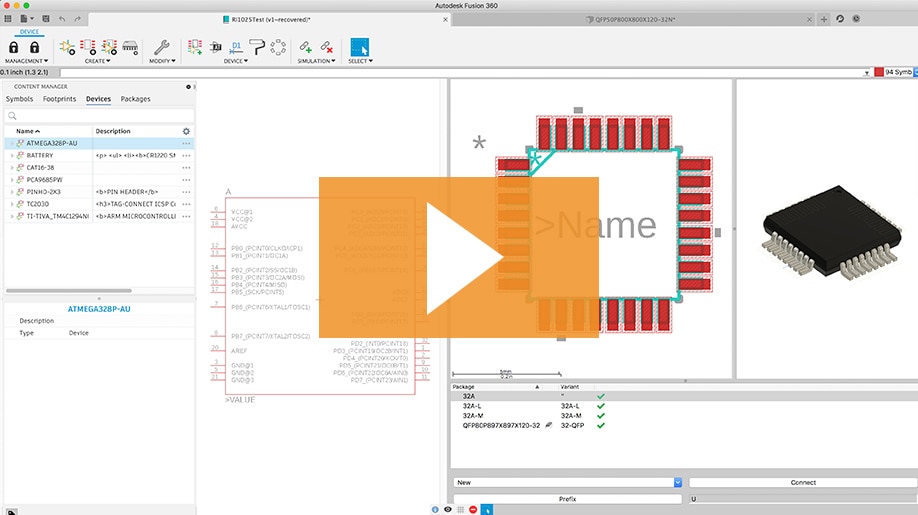

- Schematic Capture

- PCB Layout

- PCB Manufacturing (CAM)

- Design for Manufacturability/DRC

- MCAD-ECAD Unification

- Component Library Management

- SPICE Simulation

- Electronics Cooling

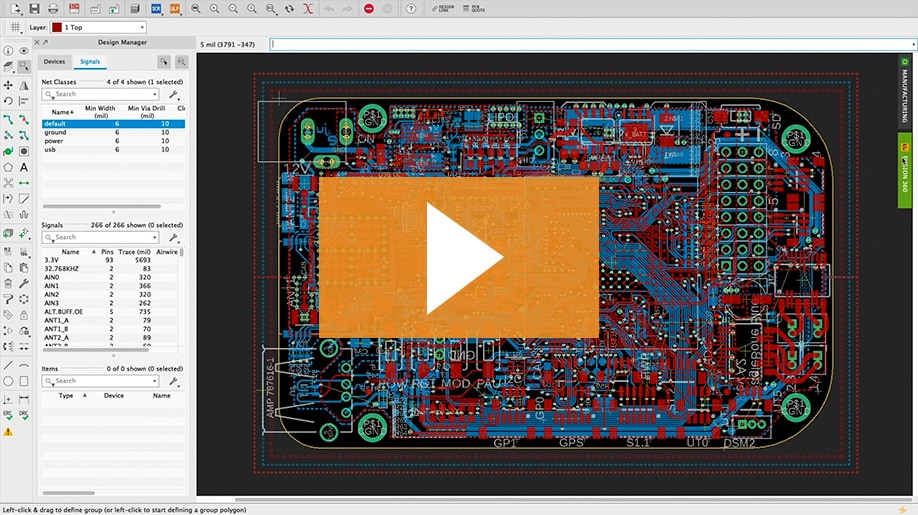

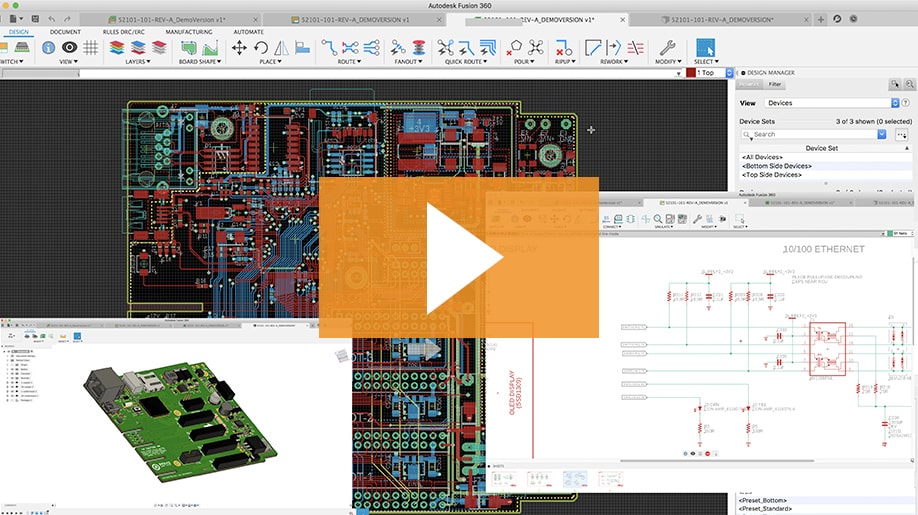

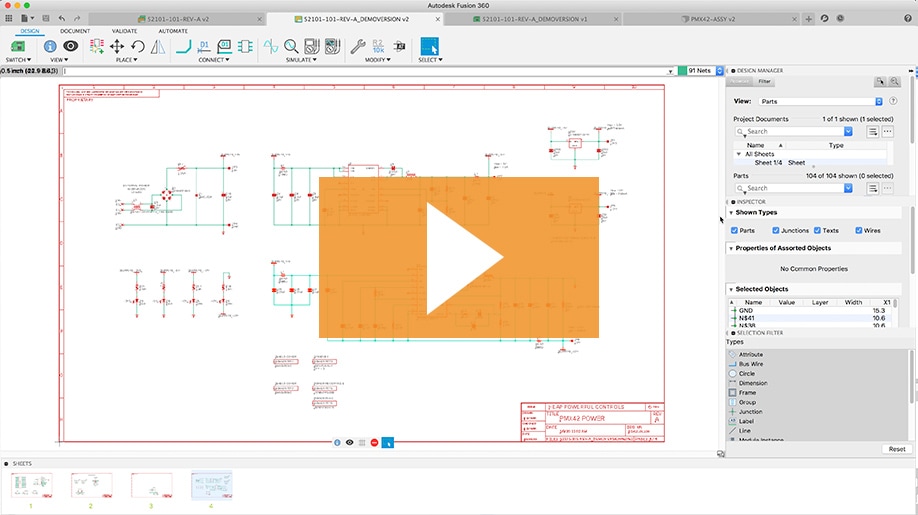

Electronics

Bring your designs to life by adding electronic intelligence using the Schematic design, PCB Layout and routing capabilities integrated in Fusion 360

Schematic Capture

Bring your spark of an idea to life with a complete set of schematic editing tools.

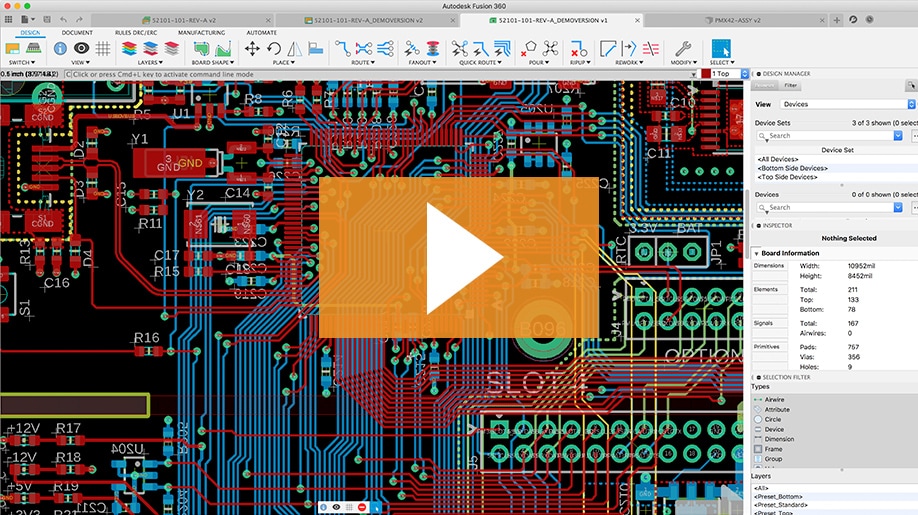

PCB Layout

Connect your ideas together in a complete design with complete PCB layout tools.

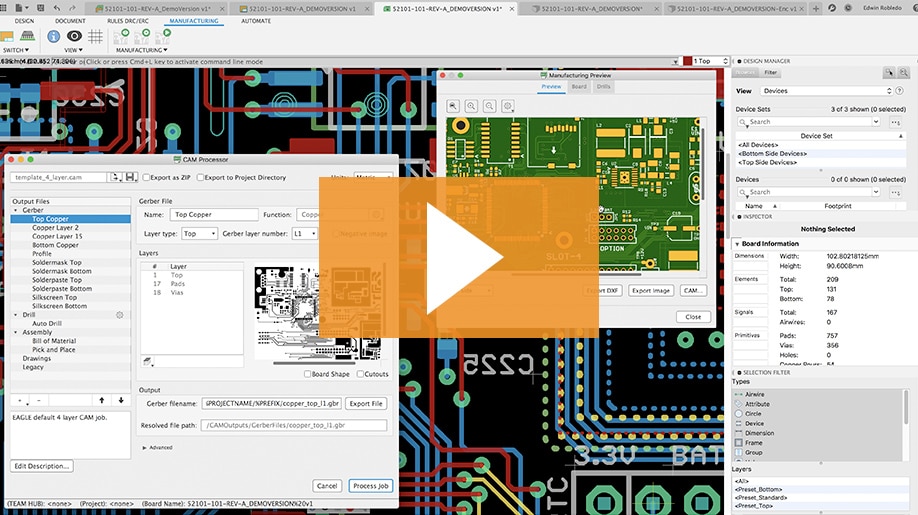

PCB Manufacturing (CAM)

Generate gerbers, drill files, and assembly files with a click of a button.

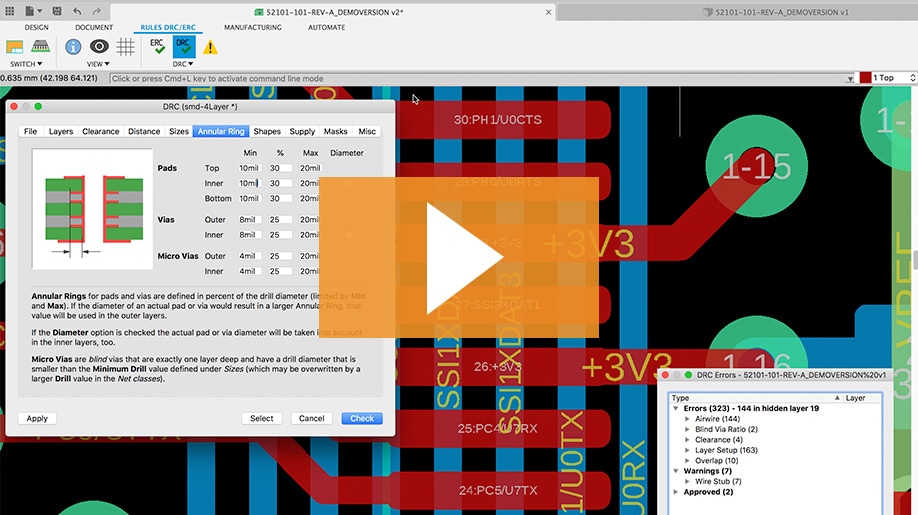

Design for Manufacturing/DRC

Stay true to your manufacturing requirements with customizable design rules.

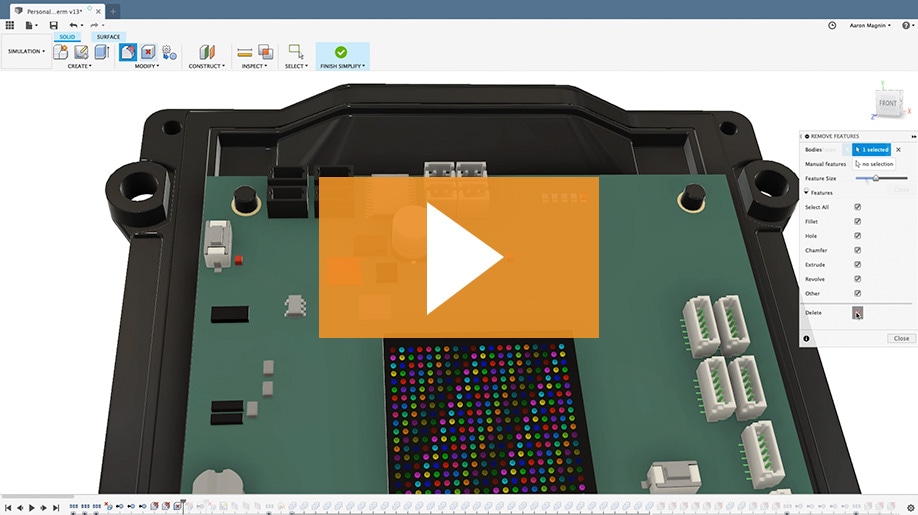

MCAD-ECAD Unification

Ensure your PCB fits the first time, every time with the only genuinely unified MCAD to ECAD software.

Component Library Management

Stay focused on your design instead of creating parts with ready to use PCB library content and component wizards.

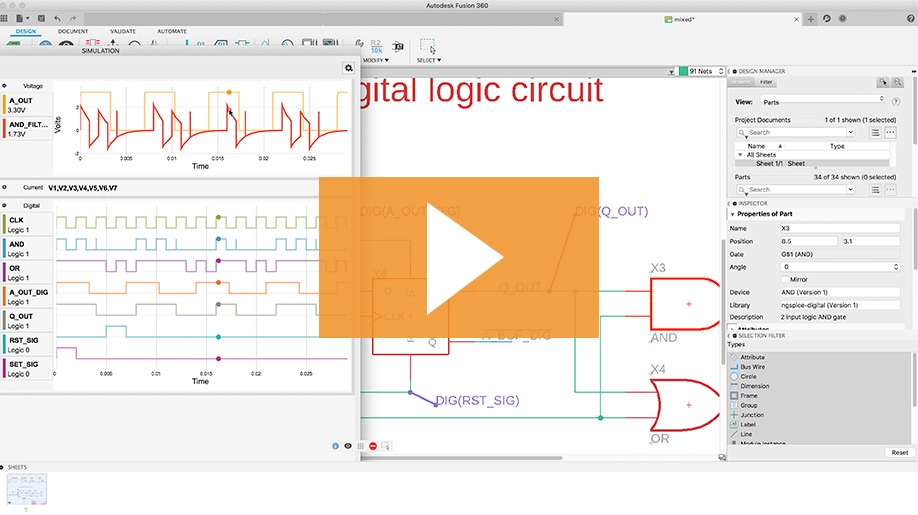

SPICE Simulation

Ensure accuracy and get your schematics right the first time with fully functional SPICE simulation.

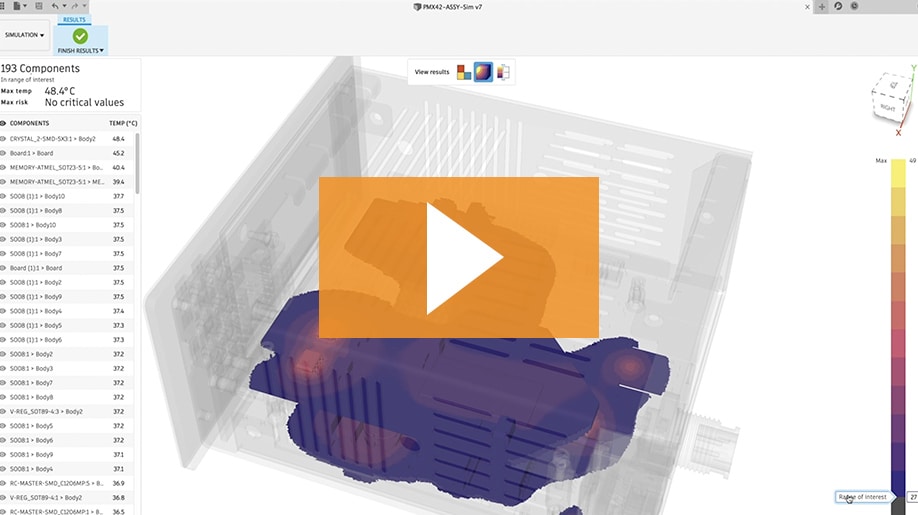

Electronics Cooling

Remove excess heat within the enclosure, so you do not damage the internal components.

- Overview

- Administrative Tools

- User Management

- File Export

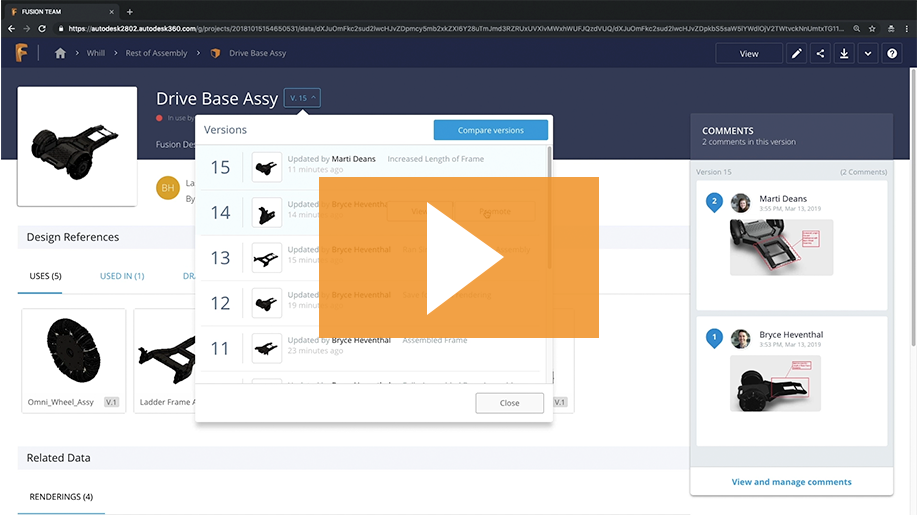

- Version Control

- Cloud Storage

- AnyCAD

- Team Participant

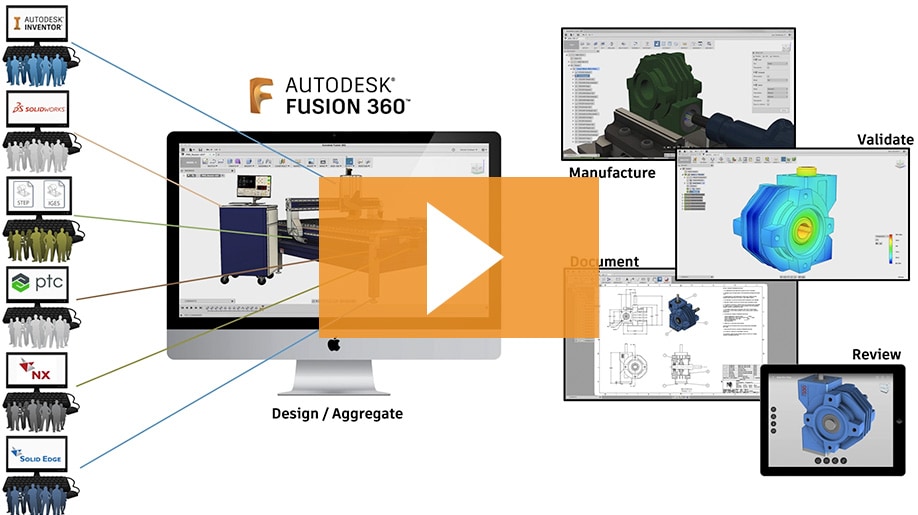

Data Management

Data management is the center of your unified development process. Gain more control by leveraging managed user permissions, version control, and cloud storage.

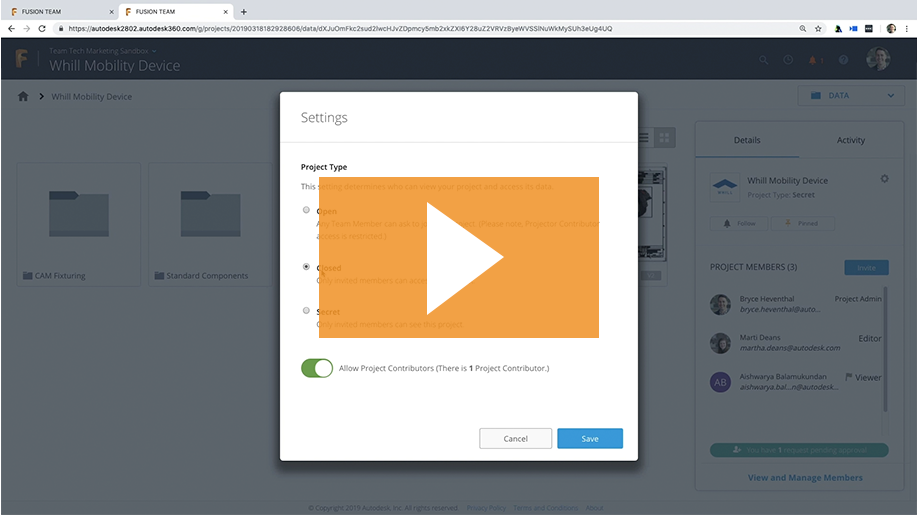

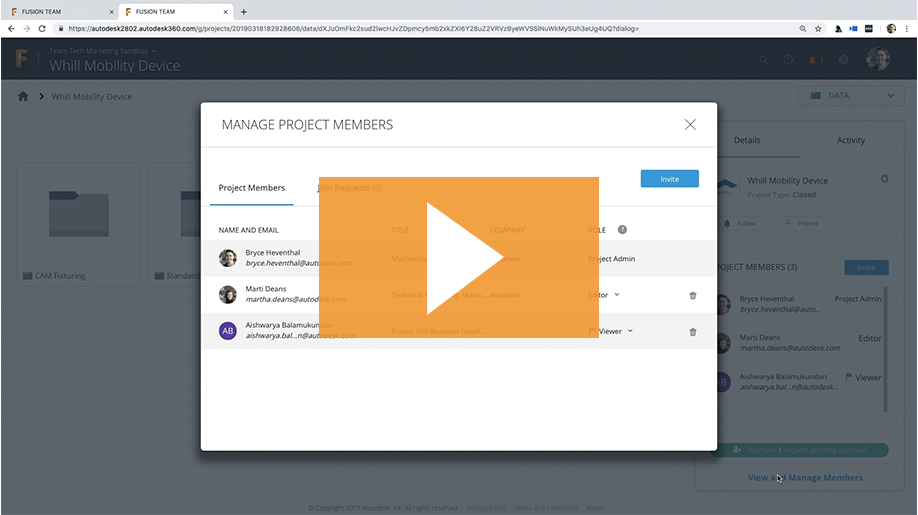

Administrative Tools

Assign permissions and grant righs to stakeholders inside or outside of your organization with a collection of advanced administrative tools.

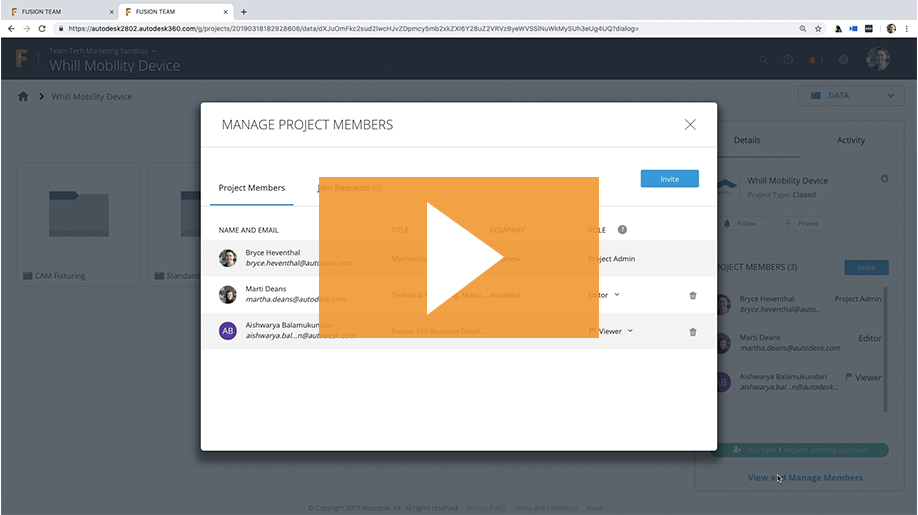

User Management

Include internal and external stakeholders in your development process. Manage how users interact with data through project administration.

We always found it challenging when we tried to share files, that is why are standardizing on Fusion 360.

- John Hamilton Design Studio Director, Coalesse

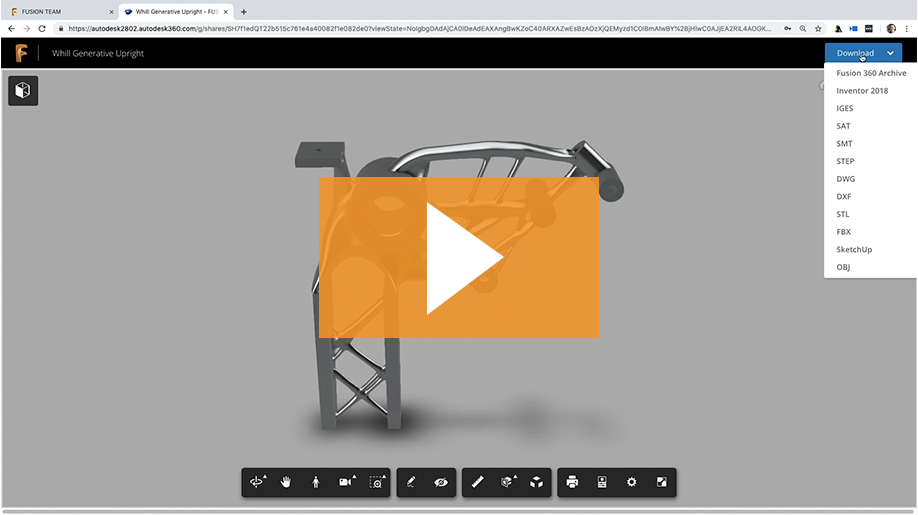

File Export

Export a variety of industry standard file formats making for easier shareability and external colleboration. Including STEP, DWG, DXF, OBJ, STL, IGES and more.

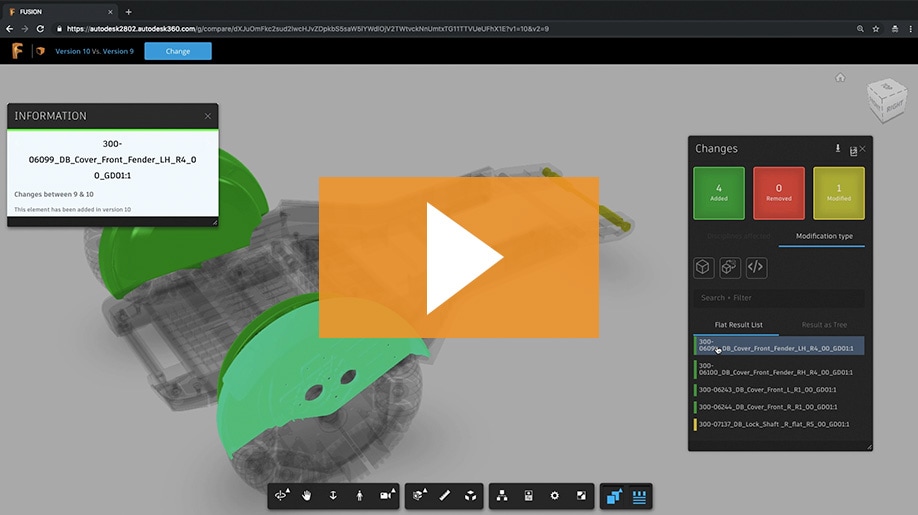

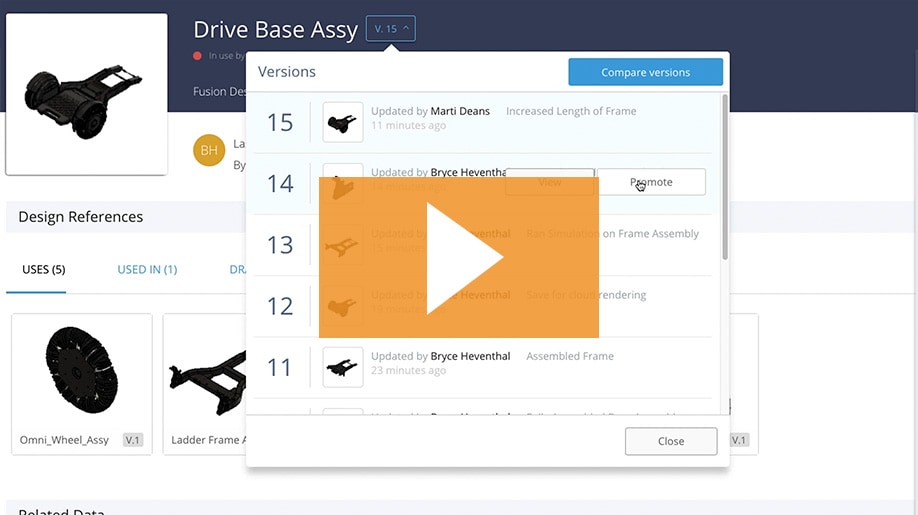

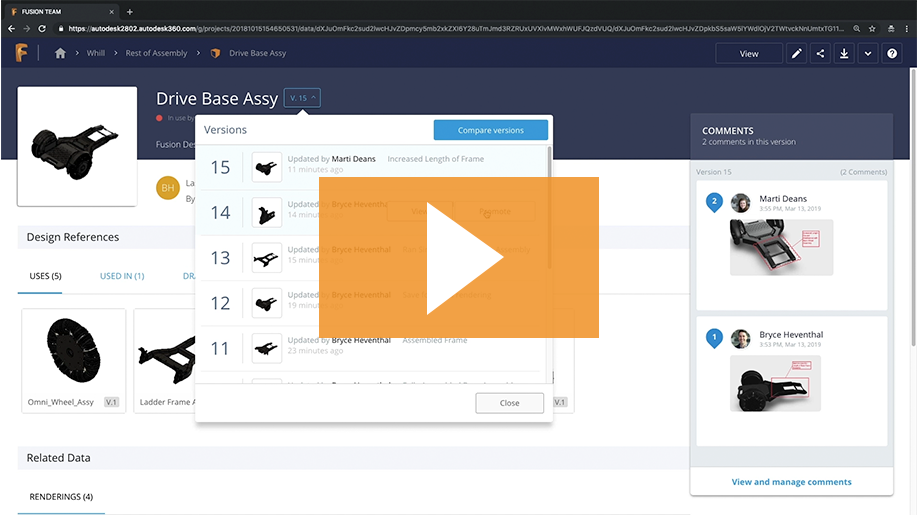

Version Control

Reduce design cycle errors and workflow inefficiencies. Track every change and prevent conflicts with automated, built-in version management.

THe ability to work at home night when the kids are asleep is second to none. You have all the files available at a mouse click.

- Johan Sandflo Founder, Sandflo Gold Co.

Cloud Storage

Access your data anywhere and everywhere, on any device. Continue working when not connected to the internet using offline mode.

It's a pretty amazing testamnet to Fusion 360 that we've done this entire design & manufacturing process from different cities.

- SweetSense

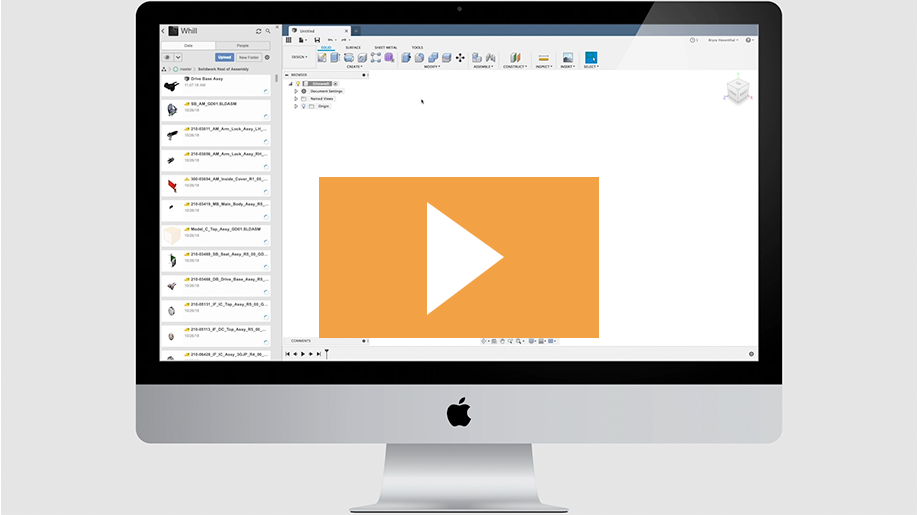

AnyCAD

Eliminate the need for translation. Use models and data from any tool directly in your Fusion 360 design.

I'm able to seamlessly import a ton of file formats. Creating tool paths in Fusion 360 is easily 50% faster than Visual Mill.

- Ryan Boyd The Wise Company

Team Participant

All data management features are included with every Fusion 360 subscription or can be purchased separately. Add users to your environment for data management and collaboration purposes only.

- Overview

- User Management

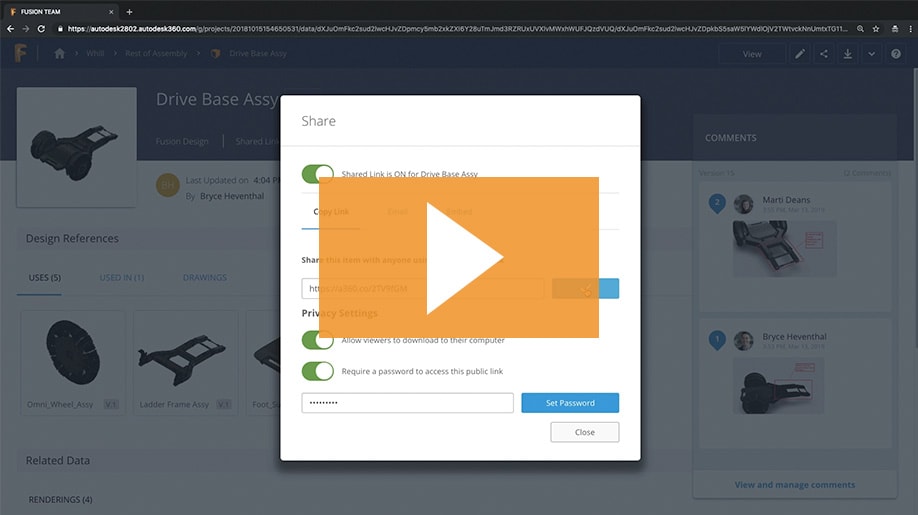

- Global Share

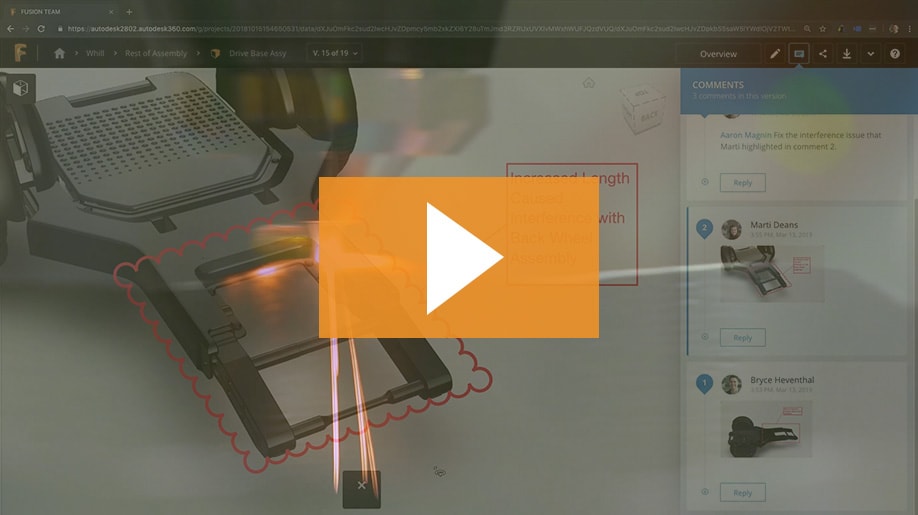

- Commenting & Redlining

- Unlimited Access

- Public/Private Design Sharing

- Team Participant

Collaboration

Remove the silos from your traditional design process and utilize a modern collaboration environment regardless of your role. Connect your teams and external stakeholders, communicate in real-time, and centralize project activity.

User Management

Include internal and external stakeholders in your development process. Manage how users interact with data through project administration.

We always found it challenging when we tried to share files, that is why are standardizing on Fusion 360.

- John Hamilton Design Studio Director, Coalesse

Global Share

Connect teams across various departments and locations, both internally and externally, using a single platform.

As a team, we are able to collaboratively use the cloud to review the current design & discuss even when not physically in the same location.

- Annika Klüpfel Breeze

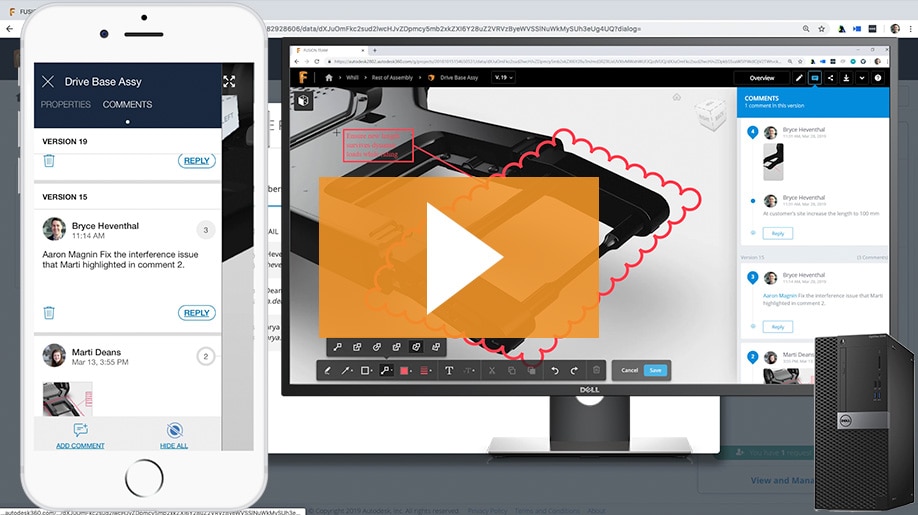

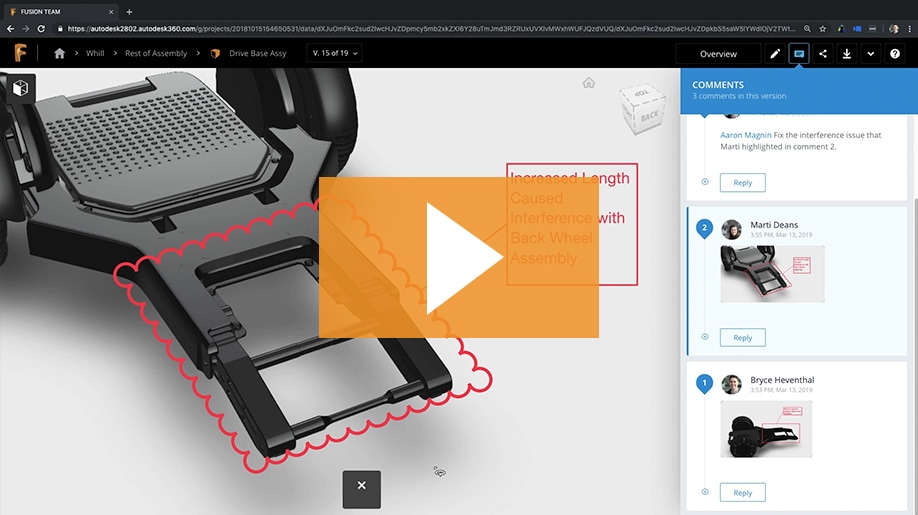

Commenting & Redlining

Capture and share feedback from any device, directly on the design using comments, redlines, and markups.

We can share projects real easy in real time with customers and partners.

- Manufacturing Shop

Cloud Storage

Access your data anywhere and everywhere, on any device. Continue working when not connected to the internet using offline mode.

It's a pretty amazing testamnet to Fusion 360 that we've done this entire design & manufacturing process from different cities.

- SweetSense

Unlimited Access

Access your data anywhere and everywhere, on any device. Continue working when not connected to the internet using offline mode.

I love that this software is cloud-based. You can access your work and your teams work anywhere!

- Kate Jovanovic G2 Crowd

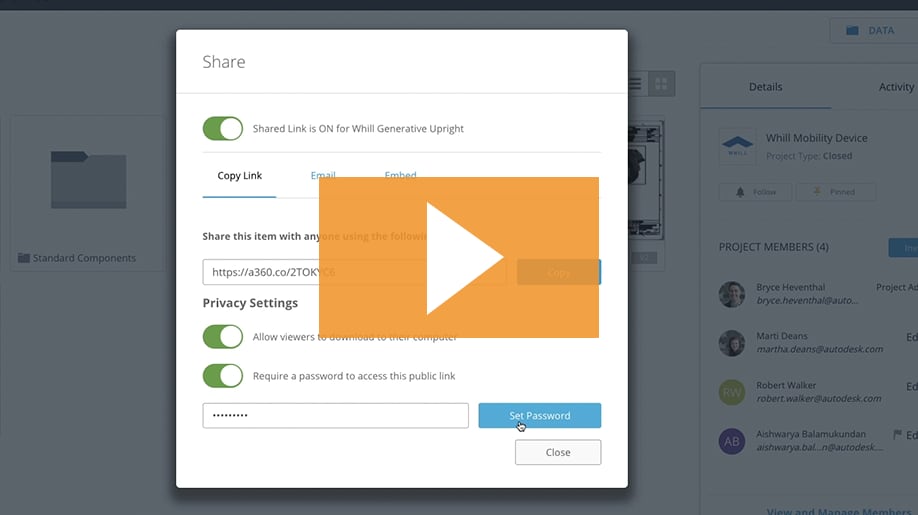

Public/Private Design Sharing

Shared links preview in a web browser, so any third parties can interact with a 3D model, even if they don't have access to a modeling program.

Previously, I had to install eDrawings, then you can’t install or read it... send an .exe... email blocks it. With Fusion 360, just send the link.

- Christian Welch Swissomation

Team Participant

All data management features are included with every Fusion 360 subscription or can be purchased separately. Add users to your environment for data management and collaboration purposes only.

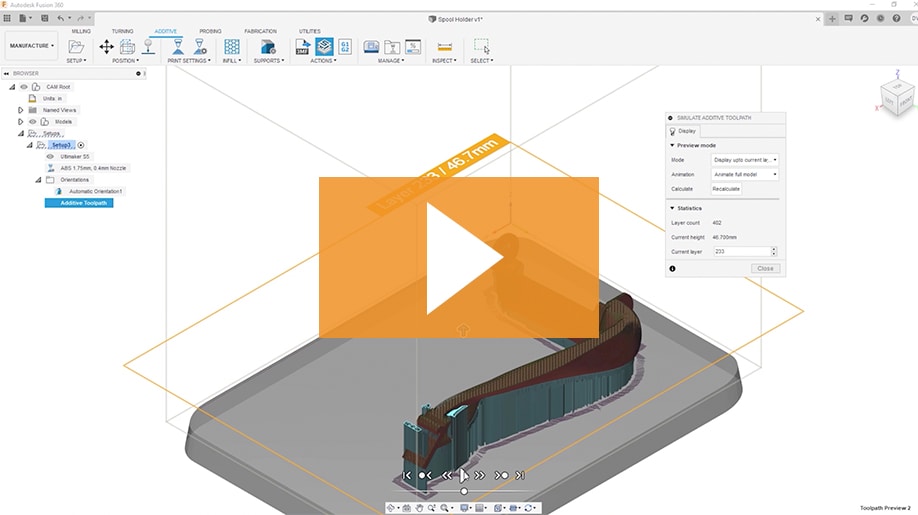

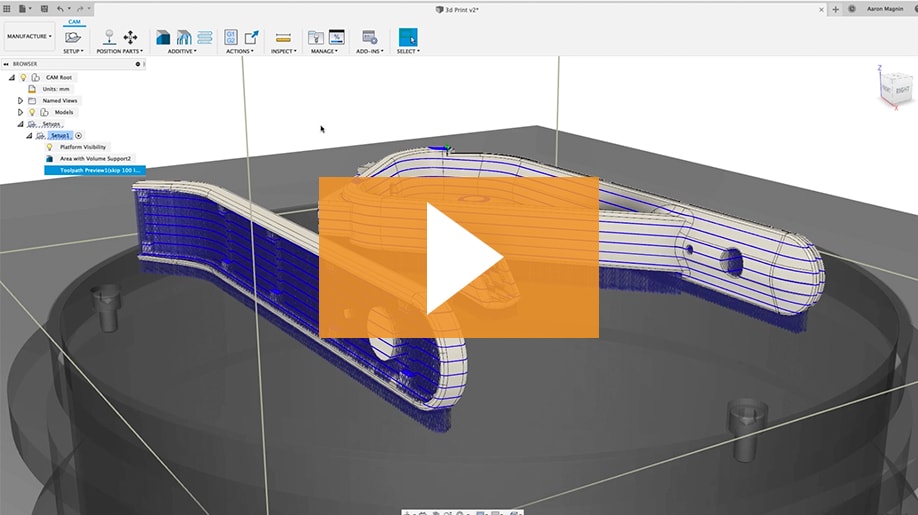

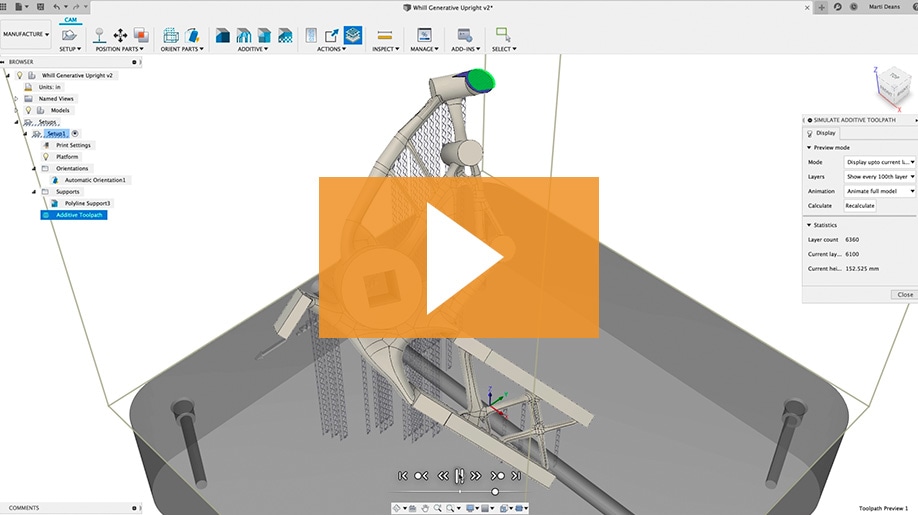

- Overview

- Fused Filament Fabrication

- Associative Programming

- Metal Additive Manufacturing

Additive Manufacturing

Quickly create physical prototypes to validate prior to manufacturing and build 3D printed parts using additive manufacturing in Fusion 360. Connect to a library of 3D printing machines including Ultimaker, EOS and Renishaw.

"Within 10 minutes, we see something in 3D and then send it to the 3D printer..

- Ian Redern Fabric

Fused Filament Fabrication

Additively manufacture parts using FFF with a seamless approach from design to print preparation. Reduce 3D printing time and save material costs with infill pattern options and automatic part orientation. Simulate slices prior to printing FFF builds across a range of additive manufacturing machines.

Associative Programming

Your toolpaths update with every design change through our fully integrated manufacturing tools, making it quick and easy to machine prototypes.

This has allowed me to reduce the production time by nearly 80%.

- Consumer Product Company

Metal Additive Manufacturing

Additively manufacture metal parts using powder bed fusion to reduce material wastage and cost. Select 3D print parameters, automatically orient parts and generate fully associative support structures.

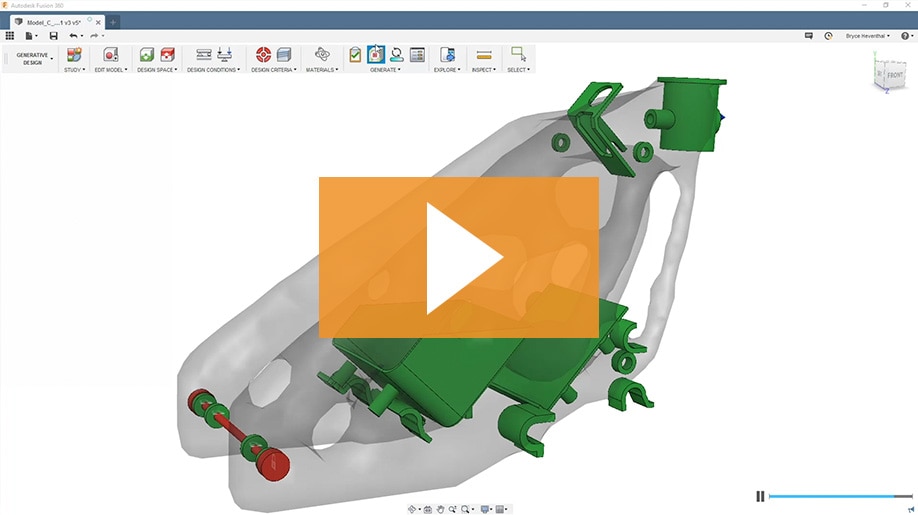

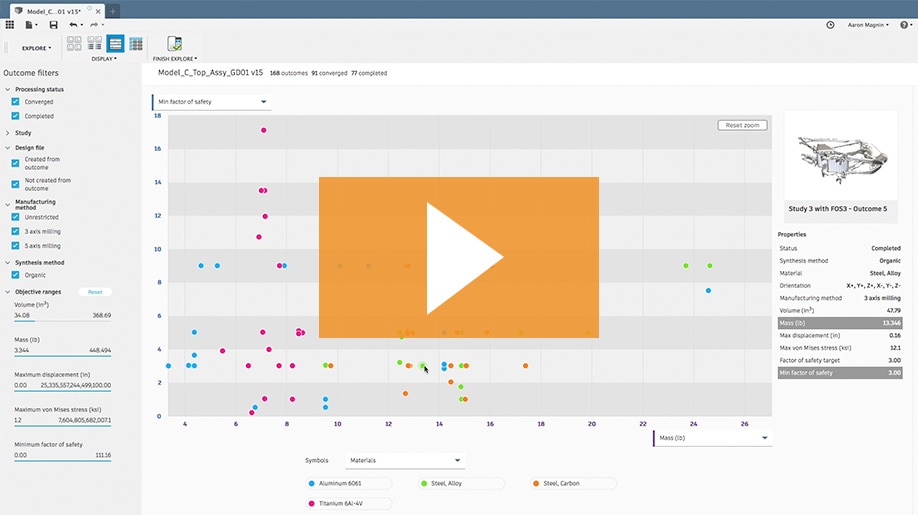

- Overview

- Manufacturing Methods & Constraints

- Machine learning & AI

- Native, Editable Results

- Cloud Solve

- Costing

Generative Design

Explore multiple manufacturing-ready outcomes that meet your design specifications while reducing weight, improving performance, and consolidating parts.

Manufacturing Methods & Constraints

Identify your design requirements, constraints, materials, and manufacturing options to generate manufacturing-ready designs.

Additive manufacturing and generative design are helping improve product performance for our customers, optimizing strength, weight, and cost.

- Steven Syzmeczek Co-founder, Penumbra

Machine Learning & AI

Review cloud-generated design outcomes based on visual similarities, plots, and filters powered by machine learning.

Generative design is so unique. It allows us to explore many different design options we wouldn't have been able to with traditional methods.

- Kevin Quinn Director, General Motors

Native, Editiable Results

Avoid lengthy, manual import-export processes. Choose your outcome and start editing in your modeling environment immediately.

Things like generative design allow us to implement, execute, and manufacture in a completely different fashion than we're thinking today.

- Frank DeSantis VP, Black & Decker

Cloud Solve

Simultaneously solve for various design outcomes, freeing up your time to focus on other tasks.

We don't have to spend months & years guessing & simulating what we think the right solution is, we look at a whole range of solutions, telling us if our idea is feasible right from the beginning.

- Matt Otto R & D Engineer, Crown Equipment

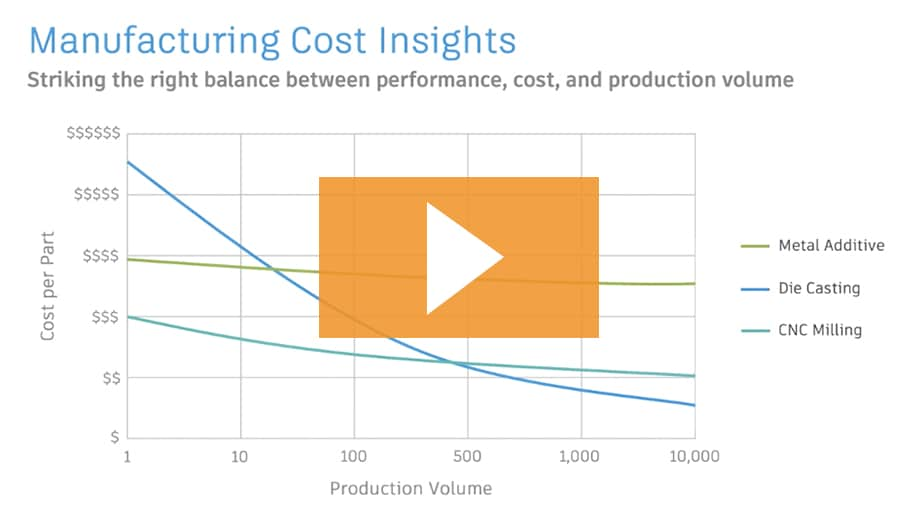

Costing

MAke the right decisions early in the design process by striking the right balance between performance and cost. Estimate your manufacturing cost, powered by aPriori, for each of the generated design outcomes, based upon production volume requirements.

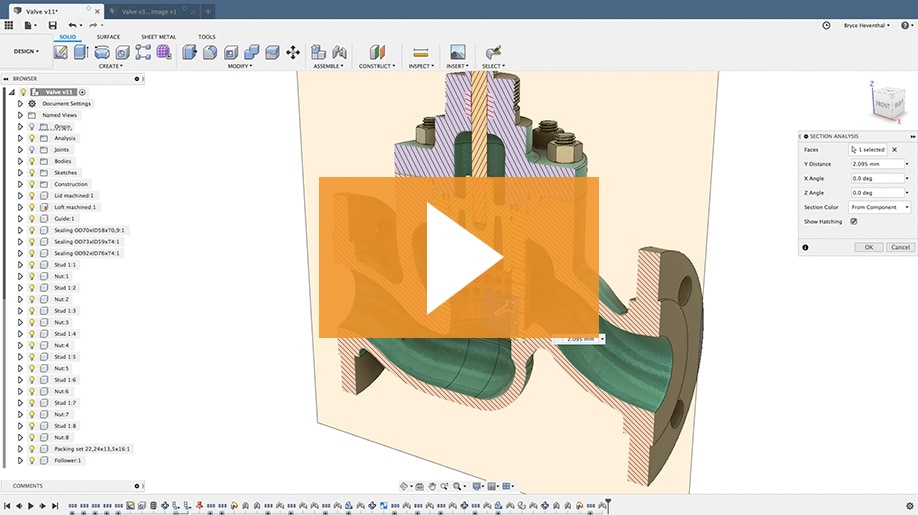

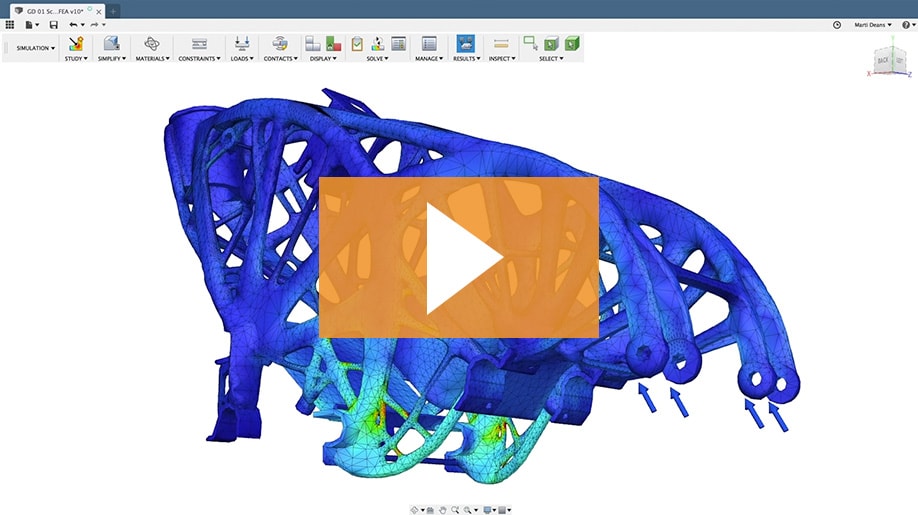

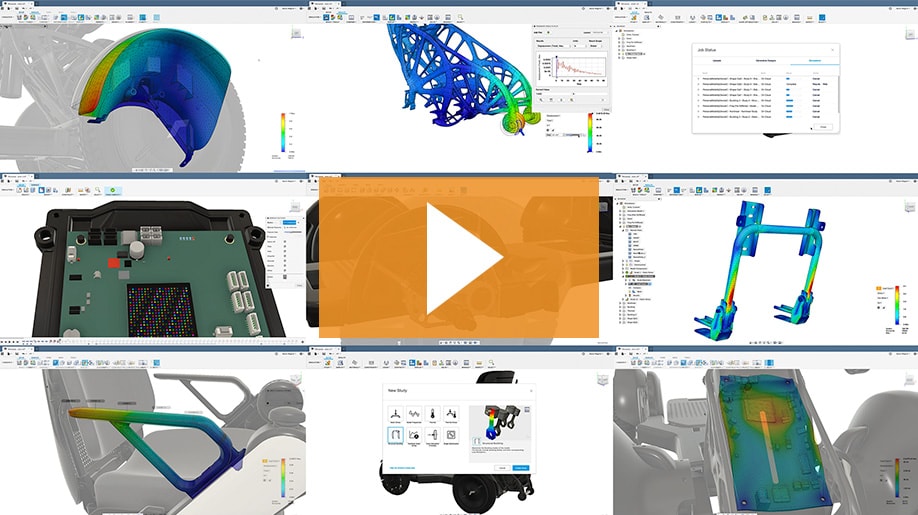

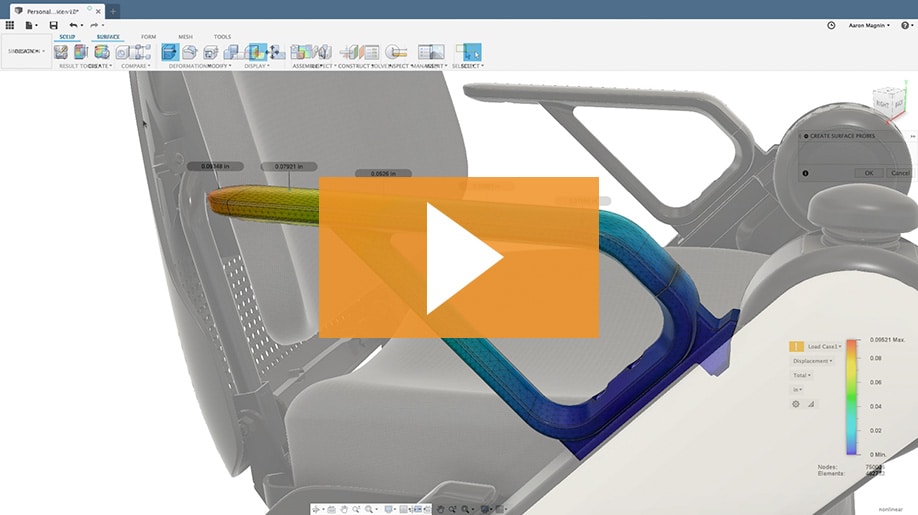

- Overview

- Cloud Simulation

- Study Breadth

- Simplify

- Compare Results

- Static Stress

- Modal Frequency

- Thermal & Thermal Stress

- Buckling

- Non-linear Stress

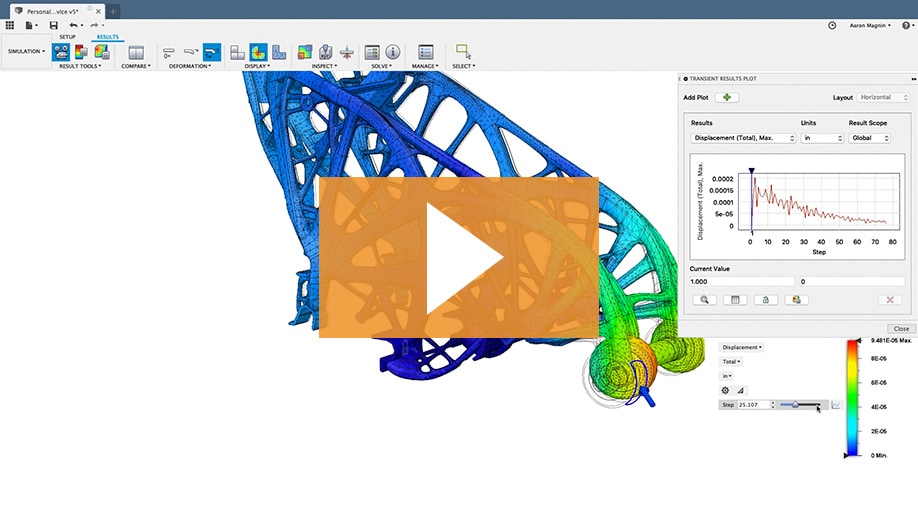

- Event Simulation

- Shape Optimization

Simulation

Test your designs to ensure they will survive real world conditions. Simulate your products digitally, reducing the cost of prototyping by using fully-validated solvers.

Cloud Simulation

Using cloud credits, setup and analyze multiple tests quickly while eliminating the need for expensive hardware.

Study Breadth

Test for up to eight different failure criterion, including nonlinear, event, and more.

Freeform modeling T-splines, parametric modeling,...[and] rendering (cloud-based), CAM and simulation, all in one product.

- Bonne Wilce

Simplify

Cut solve time or explore design changes specific to the simulation workspace.

Fusion 360 is superior in terms of its low price & the possibility of using it for the entire workflow, from modeling to analysis to rendering.

- Tatsuhiko Sekiya Photosynthp

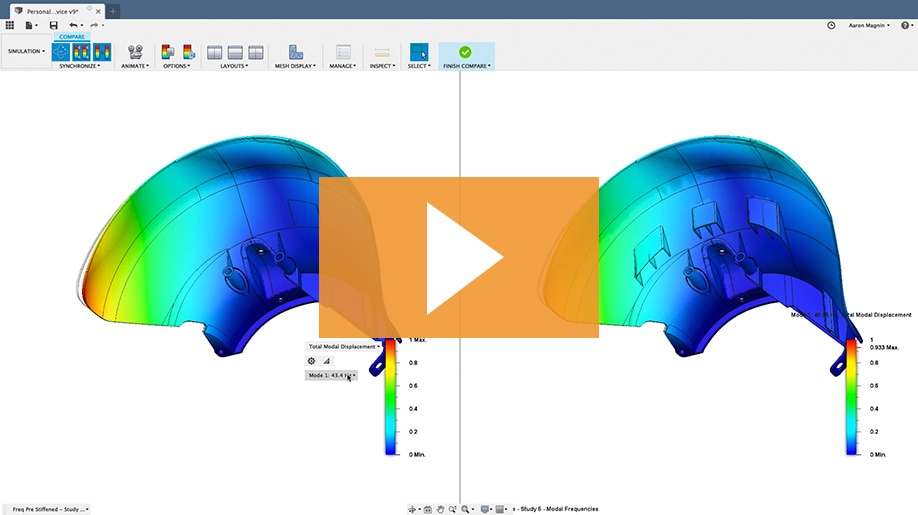

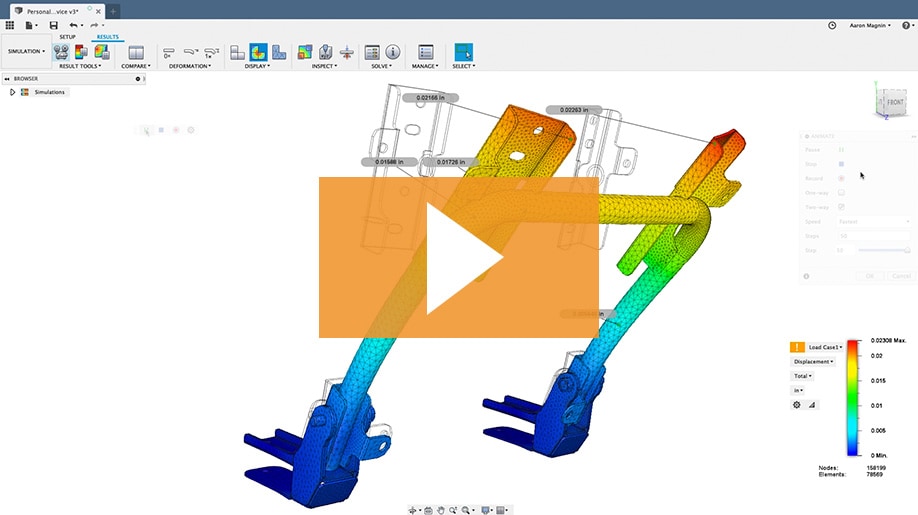

Compare Results

Easily visualize the benefits of design changes across 4 different iterations in a single, synchronized view.

We had all different kind of software packages, right now everything is integrated into the same software, and it’s so easy to use.

- Timon Alferink Engineer, KMP Motorsport Products

Static Stress

Determine displacements, stresses, and other effects resulting from static loads on parts or assemblies.

I also love the versatility of being able to model and stress test all in the same platform. Perfection!

- Chris Johnson Customer Success Representative

Modal Frequency

Avoid destructive vibration by understanding the natural frequencies of your systems.

We require scalable, flexible, cost-effective tools, focused on innovation and value, rather than squeezing max revenue from dated software.

- Mechanical Engineer Small Engineering Firm

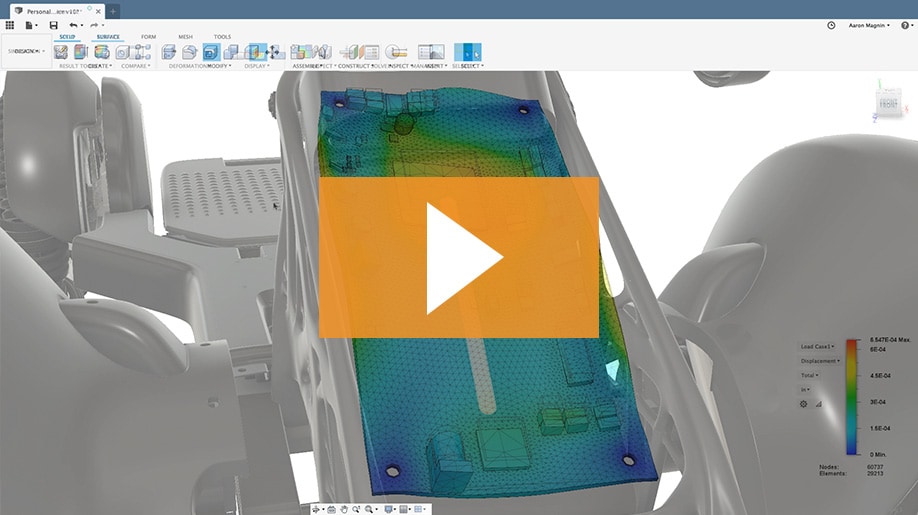

Thermal & Thermal Stress

Understand thermal distributions and how they interact with physical forces.

It's amazing how CAD programs just keep getting harder to use. Except for this one.

- Luciana Montivero

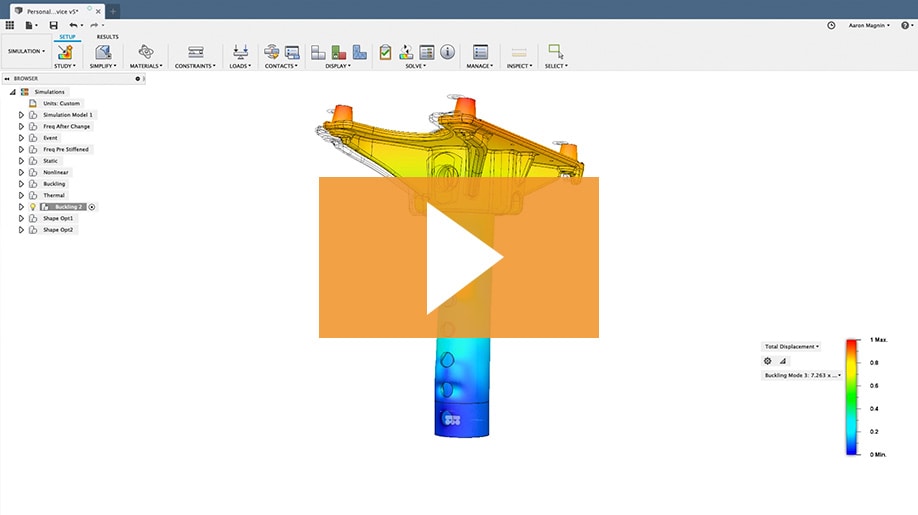

Buckling

Predict unexpected failure modes for slender members under compression using simulation.

I also love the versatility of being able to model and stress test all in the same platform. Perfection!

- Chris Johnson Customer Success Representative

Non-linear Stress

Analyze permanent deformations and nonlinear materials of your design.

With Fusion 360, we can quickly flip between modeling, rendering, and FEA.

- Adam Ellison Co-founder, Modbot

Event Simulation

Ensure your design will withstand various impact scenarios.

I fell in love with how easy it is to use.

- Johan Sandflo Founder, SandFlo Golf Co.

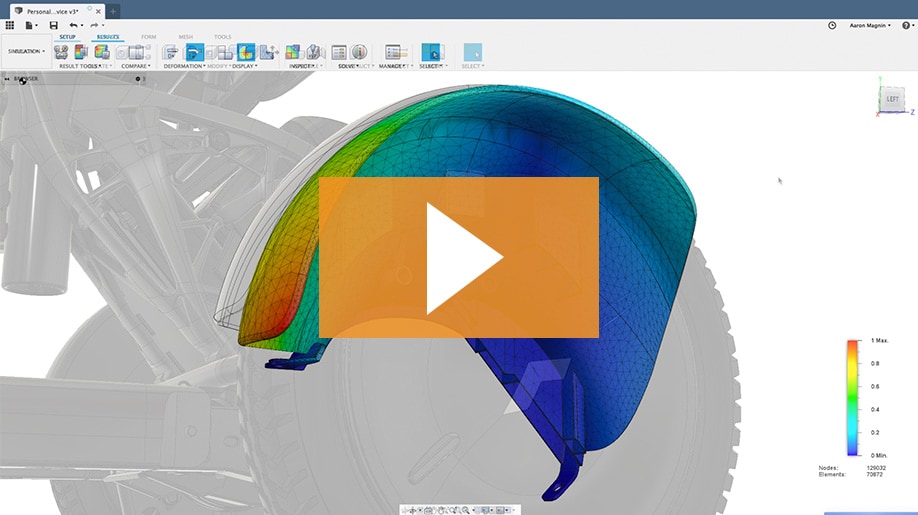

Shape Optimization

Identify unnecessary regions in your design for light-weighting, utilizing integrated simulation.

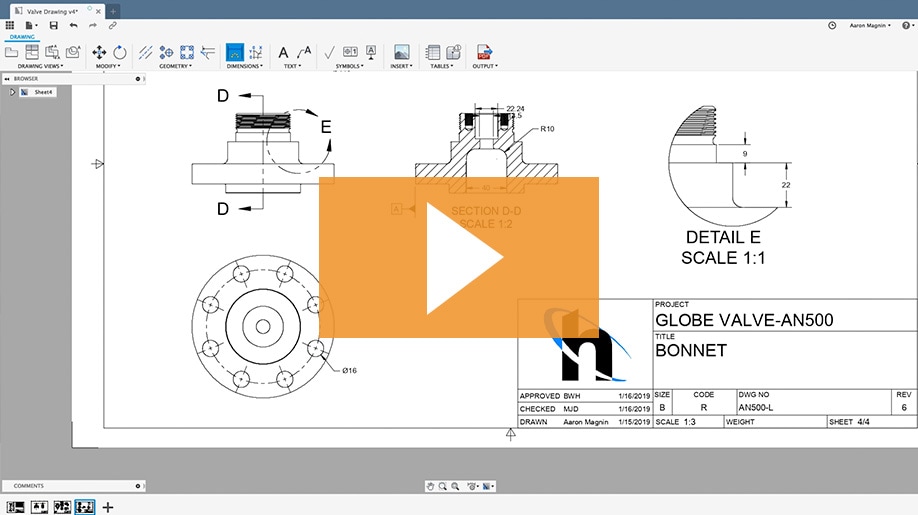

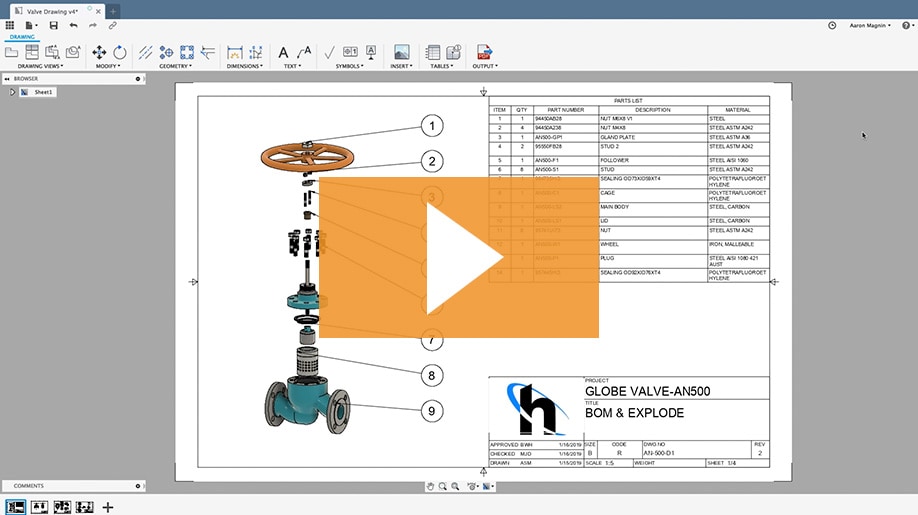

- Overview

- 2D Manufacturing Drawings

- Rendering

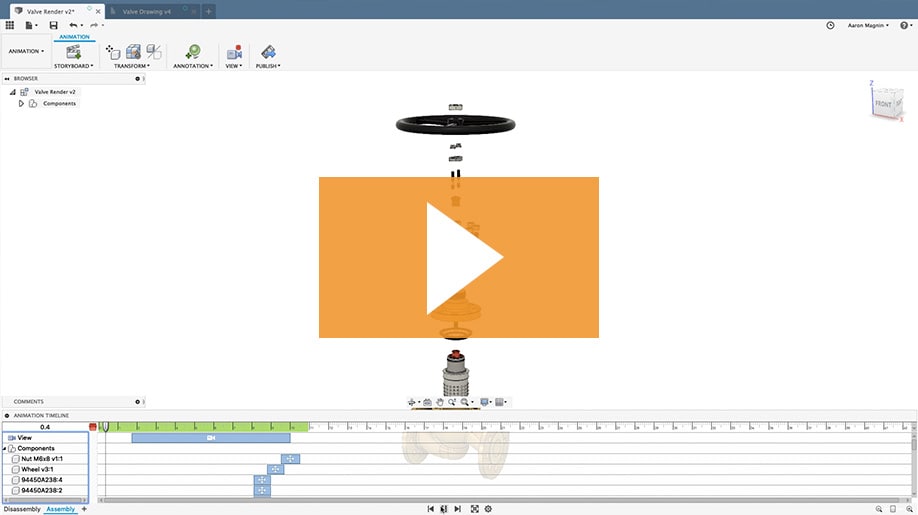

- Animation

Documentation

Communicate your designs to internal or external stakeholders with 2D manufacturing drawings, renderings, and animations.

2D Manufacturing Drawings

Document manufacturing specifications using integrated, associative drawings for parts and assemblies

Fusion 360 has helped us get concepts designed quicker and with more iterations. What used to take days now is done in hours.

- Jim McWherter Brand Motion

Rendering

Create photo-realistic images of your model, leveraging lcoal or cloud rendering.

It allows me to resolve the form in 3D and create renderings for presentations 50% faster than existing tools.

- Deborah Laun Brownlie Design

Animation

Communicate your designs with 3D exploded views and animations to show design assembly.

A prototype can be designed, animated, and shaded, all within the course of a few hours, rather than tens of hours.

- Christopher Acevedo G2Crowd

- Overview

- Machining

- Generative Design

- Additive Build

Fusion 360 Extensions

Access our most advanced design and manufacturing technology with Fusion 360 extensions to get even more from your Fusion 360 subscription. Flexible purchasing options help you access the tools your business needs today and support your growth in the future.

Machining

Extend the CAM capabilities of Fusion 360 with more advanced manufacturing technologies, including 5-axis programming, toolpath optimization, process automation, on-machine verification, and more.

Generative Design

Discover ideas beyond the reach of human capacity. Explore unlimited ideas and optimize designs for specific materials and manufacturing techniques with the Generative Design Extension.

Additive Build

Additively manufacture metal parts using powder bed fusion to reduce material wastage and cost. Select 3D print parameters, automatically orient parts, and generate fully associative support structures for efficient programming. Quickly create substractive finishing operations within your same Fusion 360 environment for high quality surface finish.