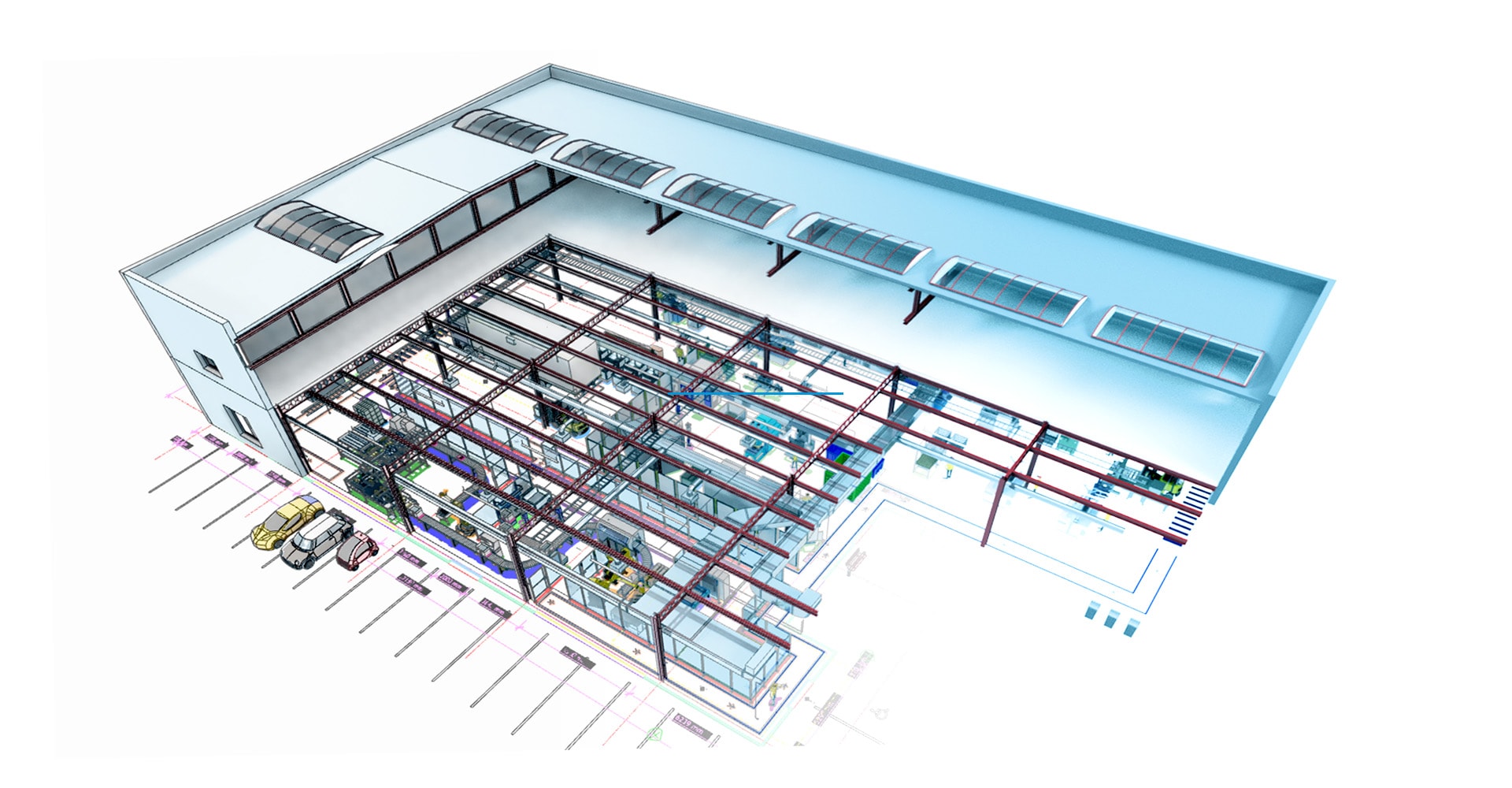

& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

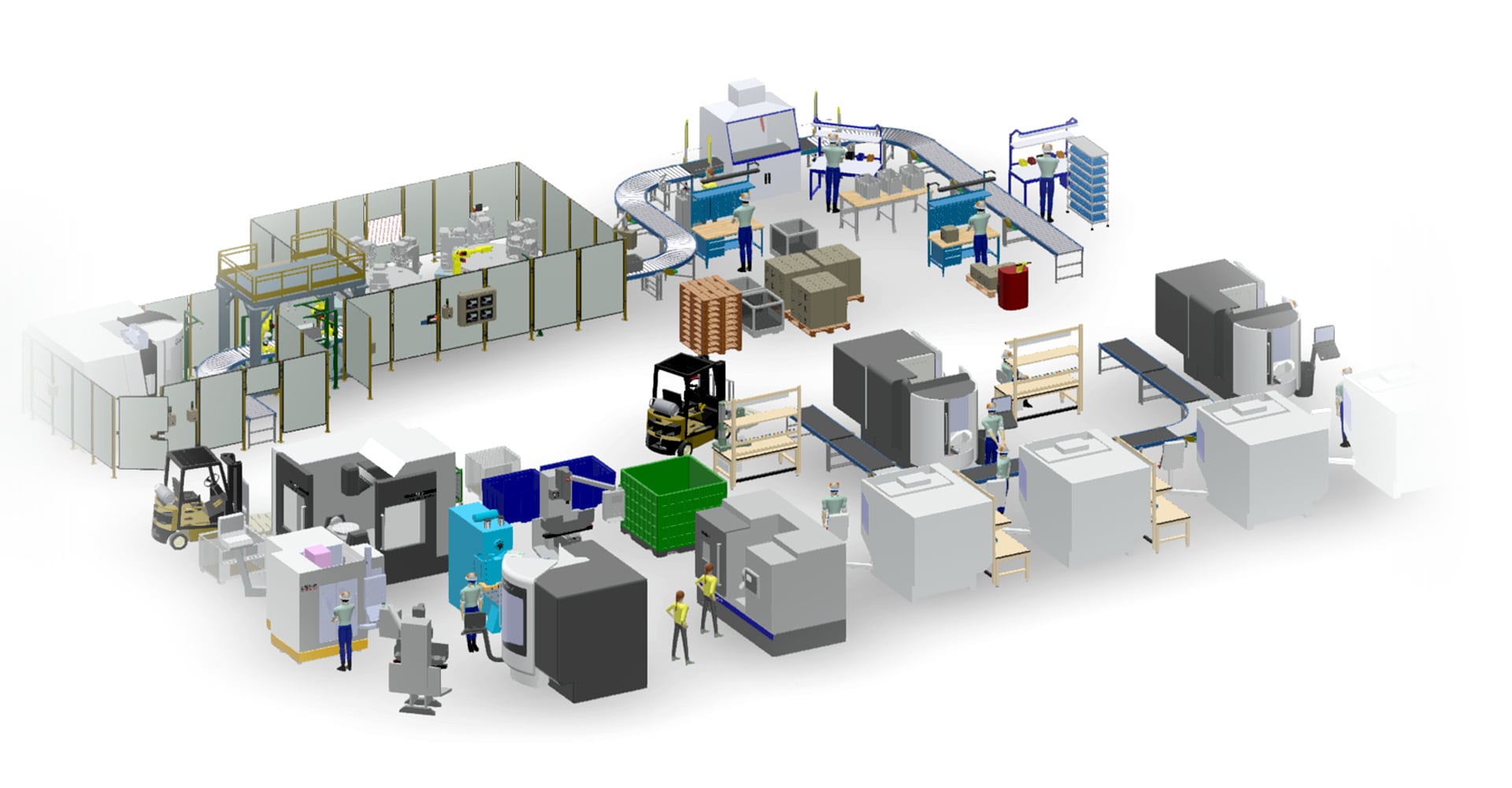

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

Worldwide Sites

You have been detected as being from . Where applicable, you can see country-specific product information, offers, and pricing.

Keyboard ALT + g to toggle grid overlay

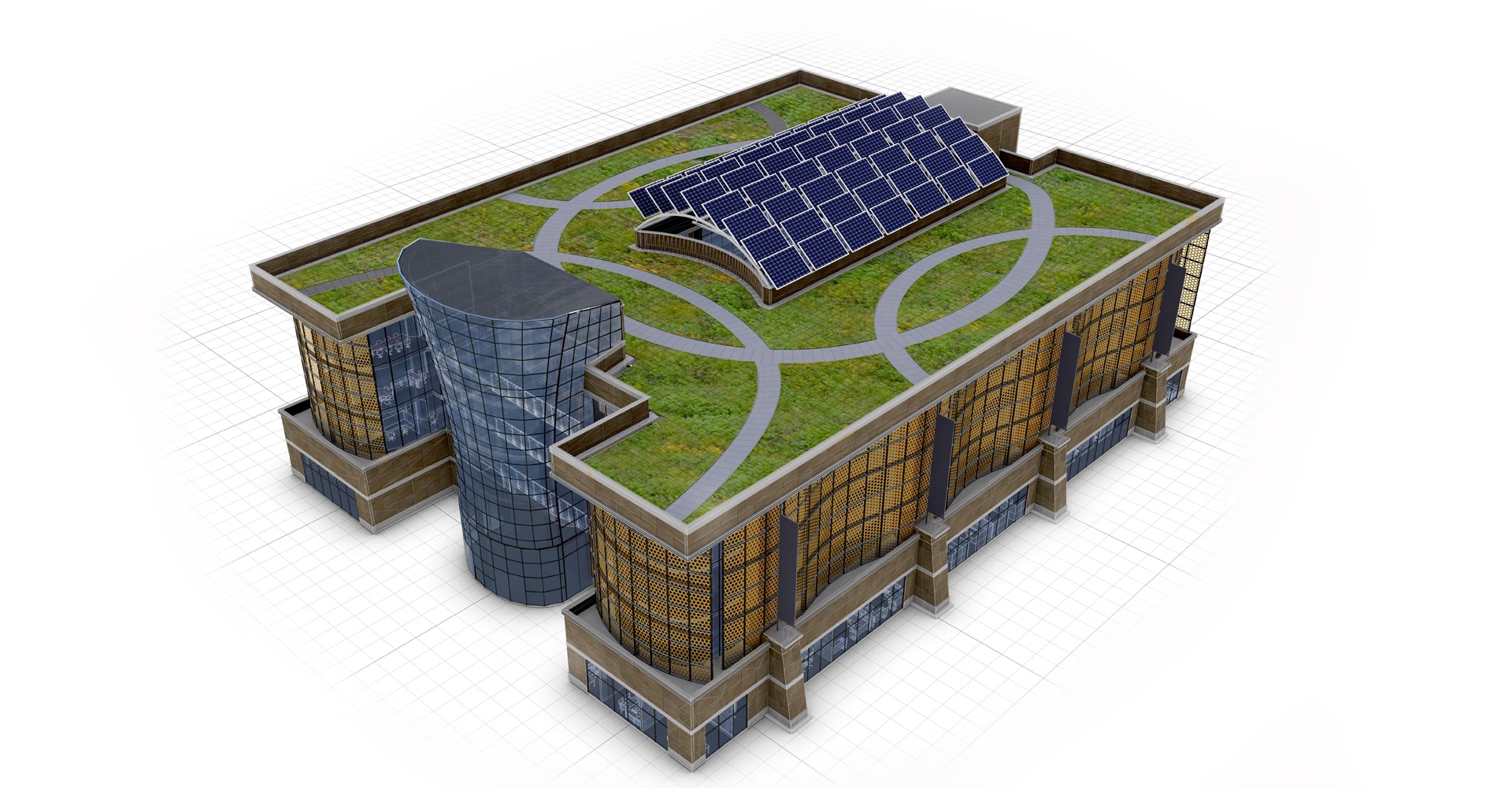

Take full advantage of your complete, unified factory model for training, ergonomic evaluations, facility management, or as a representation of your factory’s digital twin.

Leverage digital workflows and simulation tools to help reach your energy and waste reduction targets, minimizing the impact of your factory on the environment.

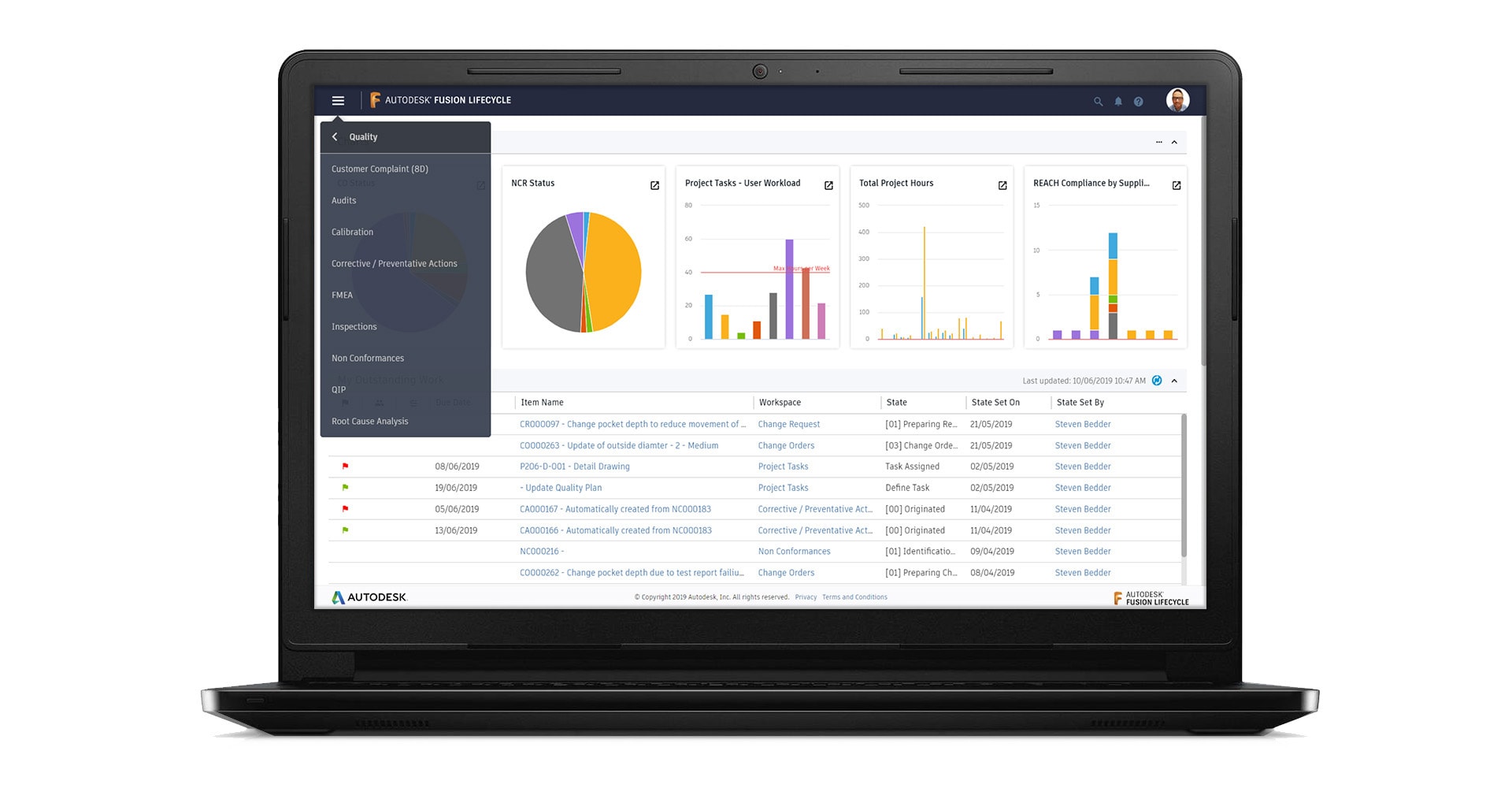

Manage your equipment assets in a centralized location — and attach calibration procedures, preventive maintenance schedules, and service documentation for easy access.

Establish a closed-loop process for managing product quality with nonconformance reporting, defined CAPA workflows, and full traceability of previous issues.

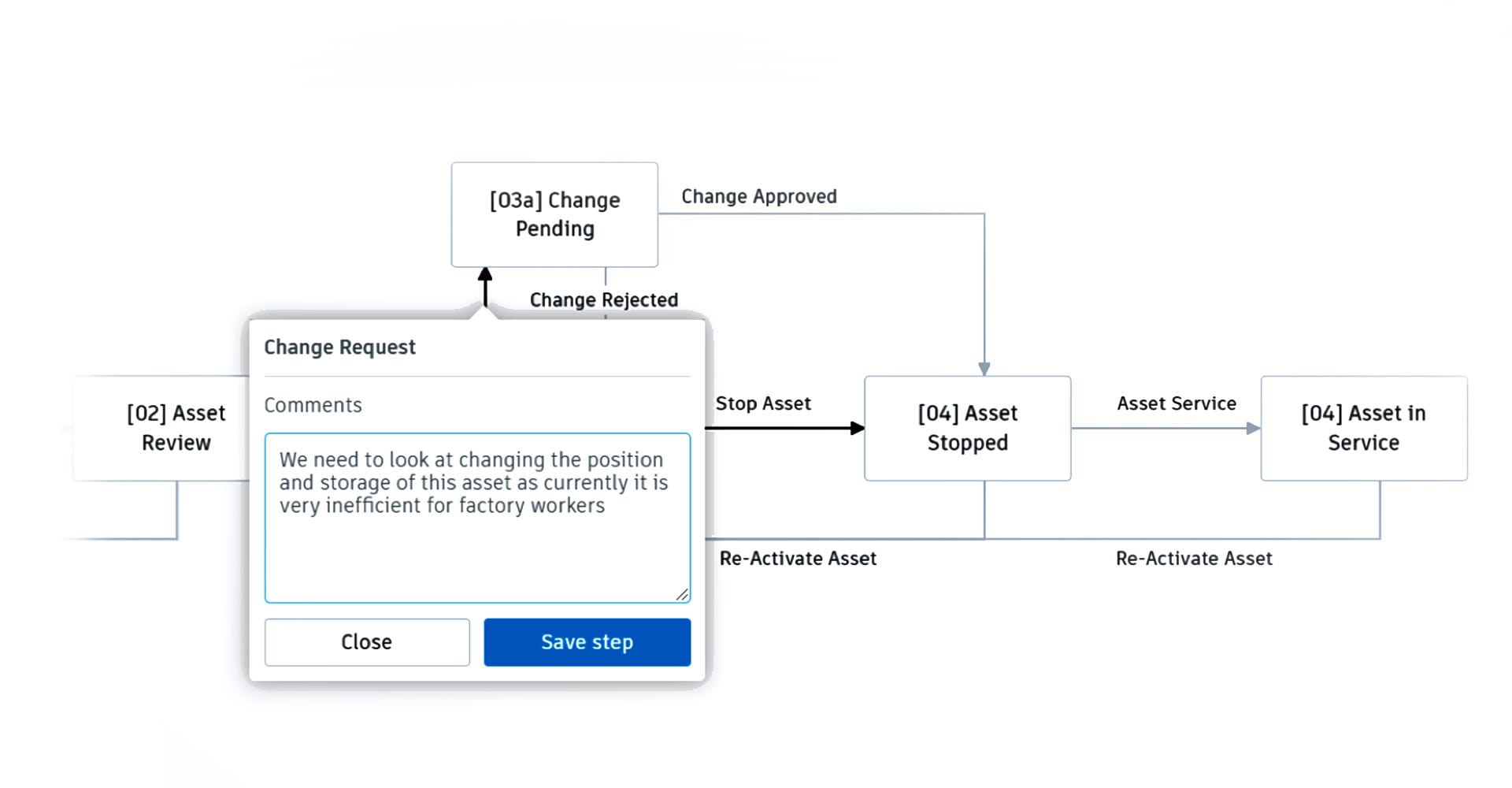

Define standard change processes while analyzing and communicating incremental change impacts. Review and report historical changes with full traceability of closed ECOs.

Download the white paper or watch an on-demand webinar to see how digital factory tools can help you adapt to changes quickly while becoming more efficient.

Manufacturing owners manage an ongoing schedule of projects to build, update, and improve facilities. Explore a new approach to production planning that leverages industry leading technology and collaboration.

Production is in a constant state of change. These changes often cause significant problems for manufacturers. Learn how to tackle your most pervasive change-related challenges with digital factory tools.