CAMplete software helps you to simulate your CAM process and identify common machine-related problems. Choose TruePath for multi-axis CNC milling machines or TurnMill for Nakamura-Tome multi-tasking machines.

Features

Post-process, simulate and optimise CNC machining code

TruePath and TurnMill common features

-

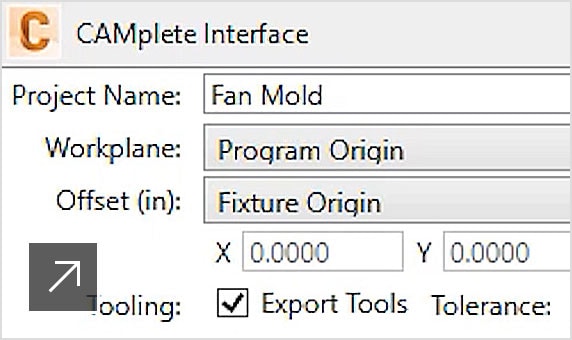

![PowerMill CAM software interface showing a dedicated plug-in to help export data into CAMplete TruePath]()

Works with CAM software

Import data files from different CAM software products before simulating, verifying and exporting safe G-code.

-

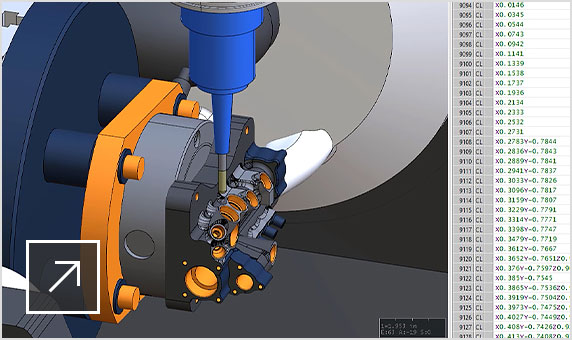

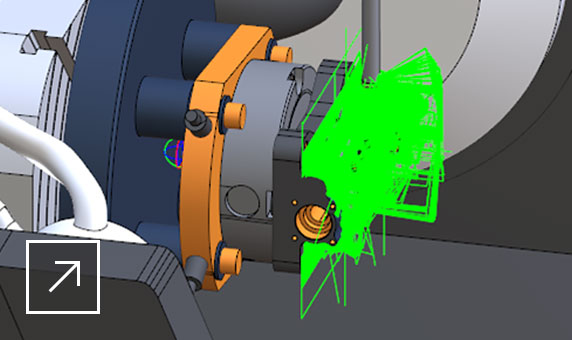

![Simulating the 5-axis machining of a manifold inside CAMplete TruePath]()

Reliable G-code verification

CAMplete uses models supplied by the machine manufacturer, resulting in highly accurate verification.

-

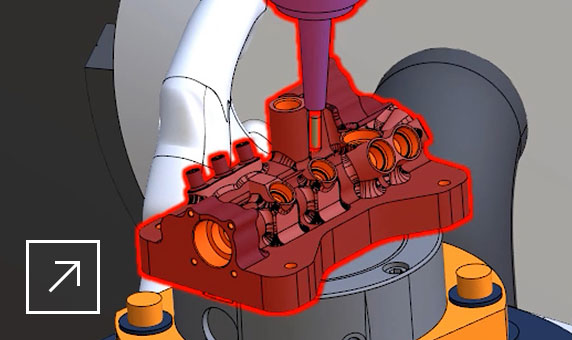

![CAMplete TruePath interface simulating a machining programme and highlighting a machine collision in red]()

Detect collisions and overtravel

Quickly identify potential crashes, near-misses, overtravel and setup errors to help avoid downtime and costly repairs.

-

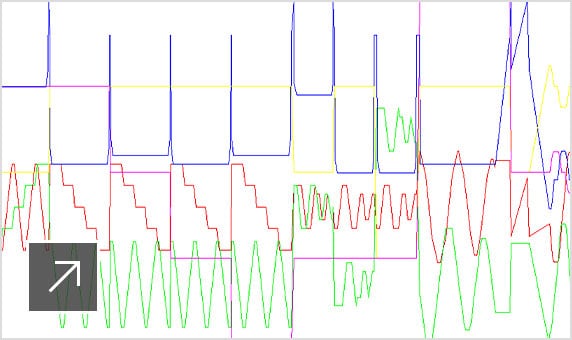

![CAMplete TruePath interface showing a graphical representation of the motion of the linear and rotary axes of a CNC machine]()

Analyse machine motion

Check the motion of individual linear and rotary machine axes to highlight problems that could affect part quality.

-

![CAMplete TruePath interface with editable options to control the output when post-processing NC code]()

Optimise G-code files

Modify key machine parameters for each G-code file before export to make better use of your CNC hardware.

-

![CAMplete TruePath user interface showing the simulation of cutting moves and non-cutting connections in a 5-axis machining programme]()

Visualise machine interpolation

Validate the full CNC machining process, including cutting motion, connection moves and tool changes.

TruePath features

-

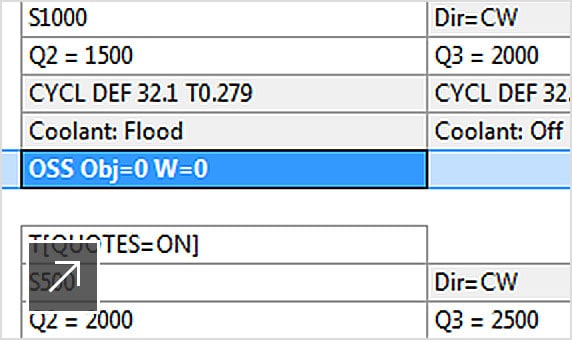

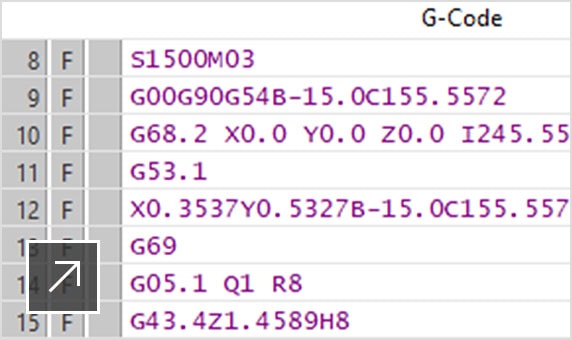

![CAMplete TruePath user interface showing a post-processed NC code file with colour coded blocks of commands]()

Proven post-processors

Output high-quality G-code using proven post-processors developed in partnership with machine tool builders.

-

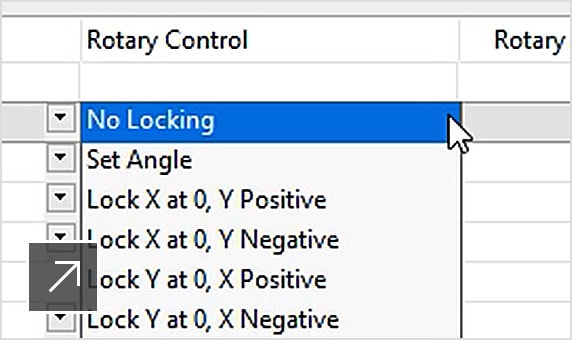

![CAMplete TruePath user interface showing rotary and tilt axis control options]()

Advanced rotary controls

Control how the rotary axes behave on your machine to avoid unexpected or hazardous movements.

-

![CAMplete TruePath user interface showing the selection of a CNC machine from a list of different machines]()

Change CNC machine

Safely run proven programs on alternate machines, even those with different kinematics or controllers.

-

Editable post-processors

Make changes to post-processor files to adjust your G-code output and run your CNC machines the way you need.

-

G-code comparison

Compare edited G-code files against your original machining NC projects to identify costly mistakes early.

-

Stock comparison

Compare the intended CAD model against virtual stock to spot differences and avoid costly mistakes.

TurnMill features

-

![CAMplete TurnMill user interface showing the simulation of a Nakamura-Tome multi-tasking machine tool]()

Multi-tasking machines

Simulation, verification and post-processing specifically developed for Nakamura-Tome machines.

-

![CAMplete TurnMill user interface showing the simulation of machining operations on the upper and lower turrets of a Nakamura-Tome CNC machine]()

Machine synchronisation

Synchronise the motion of turrets, main and sub-spindles, live tooling and part transfers on multi-tasking machines.

-

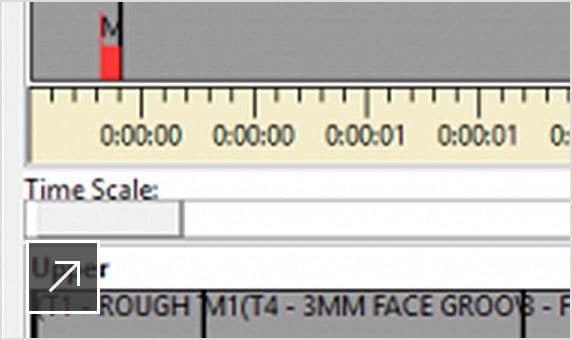

![CAMplete TurnMill user interface showing a timeline representation of machining operations working on the upper and lower turrets of a CNC machine]()

Time-based optimisation

Analyse multi-tasking operations and subroutines to improve efficiency and reduce overall machining cycle times.

-

Flexible process development

Modify entire operations and reassign tooling to different machining positions to shorten development times.