NC-code post-processing and G-code simulation software

Overview

What is CAMplete?

-

TruePath overview (video: 1.40 min.)

-

TurnMill overview (video: 1.26 min.)

-

![PowerMill CAM software plug-in showing the export of data to CAMplete]()

CAMplete TruePath and TurnMill work with leading CAM software

-

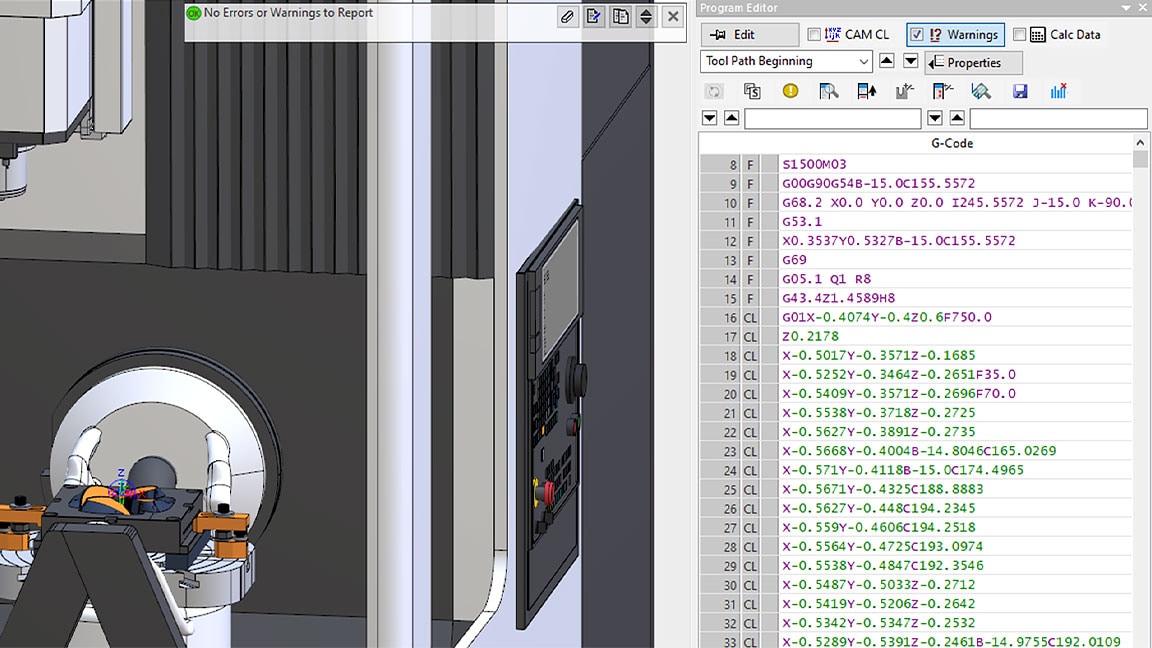

![CAMplete TruePath user interface showing post-processed NC code]()

Proven post-processors help produce safe and efficient NC code

-

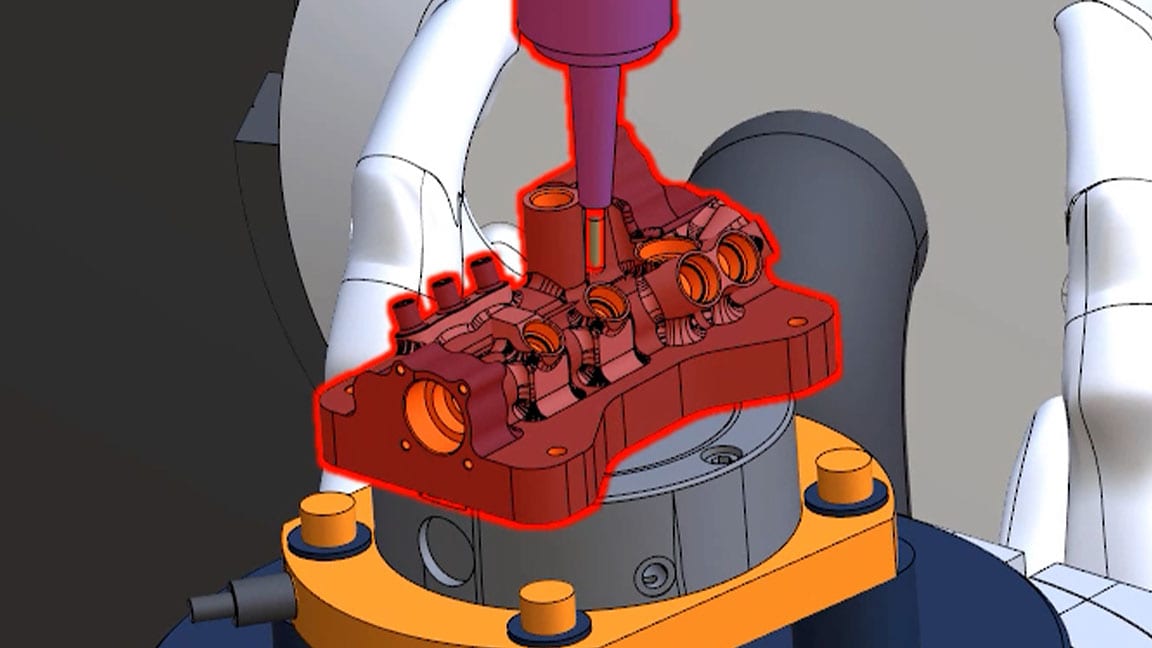

![Simulating a CNC machine collision inside CAMplete TruePath]()

CAMplete TruePath highlights collisions to avoid costly mistakes

-

![CAMplete TurnMill user interface showing a Nakamura-Tome multi-tasking machine]()

TurnMill works with Nakamura-Tome multi-tasking machines

-

CAMplete software provides G-code post-processing, verification and simulation for different kinds of CNC machinery. Import data from leading CAM software, then use proven post-processors and highly accurate 3D machine models, developed in partnership with machine tool builders, to quickly produce high-quality, collision free NC machining code.

- CAMplete TruePath for multi-axis milling machines

- CAMplete TurnMill for Nakamura-Tome multi-tasking machines

Proven post-processing for your CNC machines

CAMplete TruePath post-processing overview (video: 1.43 min.)

CAMplete uses customisable post-processors, developed in partnership with machine tool builders, to convert your CAM software files into safe NC machining code.

- Import APT or CL data from CAM software.

- Combine toolpaths from different CAM systems in a single project.

- Export optimised G-code files to suit your specific CNC machine.

G-code verification

G-code verification overview (video: 1.45 min.)

Tools for 5-axis simulation and verification help you to know how your machine will behave before you run a single line of G-code.

- Detect collisions, near-misses, overtravel and set-up errors.

- Protect your machines, workpieces, fixturing and workforce.

- Use with your CAM software to optimise machine motion.

- Reduce the time taken to install new machines.

Which CAMplete is right for you?

-

![Simulating the 5-axis machining of a complex fan component inside CAMplete TruePath]()

CAMplete TruePath

Customisable post-processors to import CL data from CAM software and convert into safe and efficient NC-code for 5-axis machines.

-

![Simulation on a Nakamura-Tome multi-tasking machine in CAMplete TurnMill]()

CAMplete TurnMill

Specialised post-processing and verification software for Nakamura-Tome multi-tasking machines with synchronisation and time-based optimisation.

How much does an CAMplete subscription cost?

Contact your local Autodesk sales team to discuss your business needs and review subscription pricing options.

Is there a free version of CAMplete?

Contact your local Autodesk sales representative to discuss your business needs to see what limited-time version of CAMplete may be available for you.

Which versions of CAMplete can I use if I subscribe to the current version?

Your Autodesk CAMplete subscription gives you access to install and use the three previous versions. Available downloads are listed in your Autodesk Account at manage.autodesk.com after subscribing. See also previous releases available for subscribers.

Can I install CAMplete on multiple computers?

With a subscription to Autodesk CAMplete TruePath or Autodesk CAMplete TurnMill software, you can install it on up to three computers or other devices. However, only the named user can sign in and use that software on a single computer at any given time. Please refer to the Software Licence Agreement (US site) for more information.

Reporting:

Product usage reporting

- See an aggregate summary of how many people are using each product and version and the overall frequency of use.

Administration & Security:

2-step verification

- Add another layer of security to user accounts.

Bulk import & assign

- Upload a .csv file to add and assign a large number of users at once.

Support & Adoption Services:

8 x 5 live support

- Contact an Autodesk specialist for help during your local working hours.

Collaboration:

Autodesk Drive

- Securely store, preview and share design data.

Shared views

- Quickly and securely share work with stakeholders.

Click here to see full list of plan features and frequently asked questions.