& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

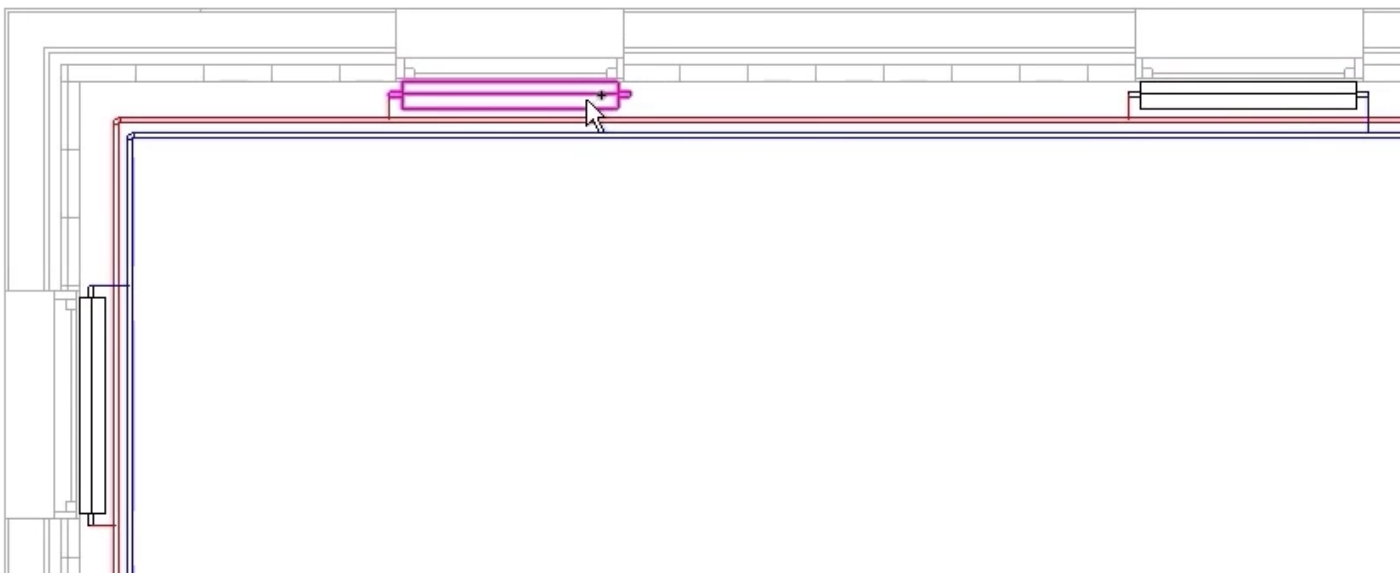

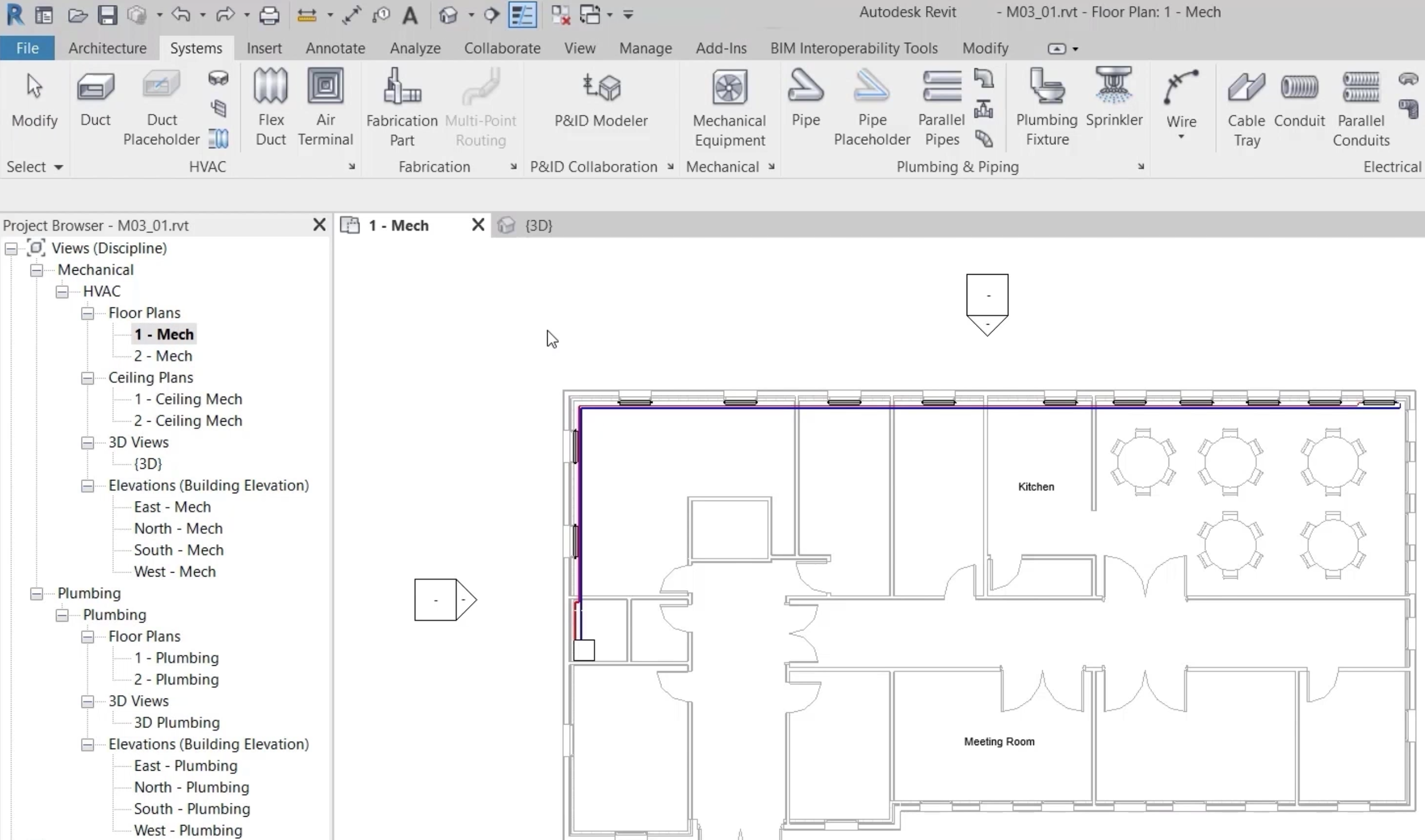

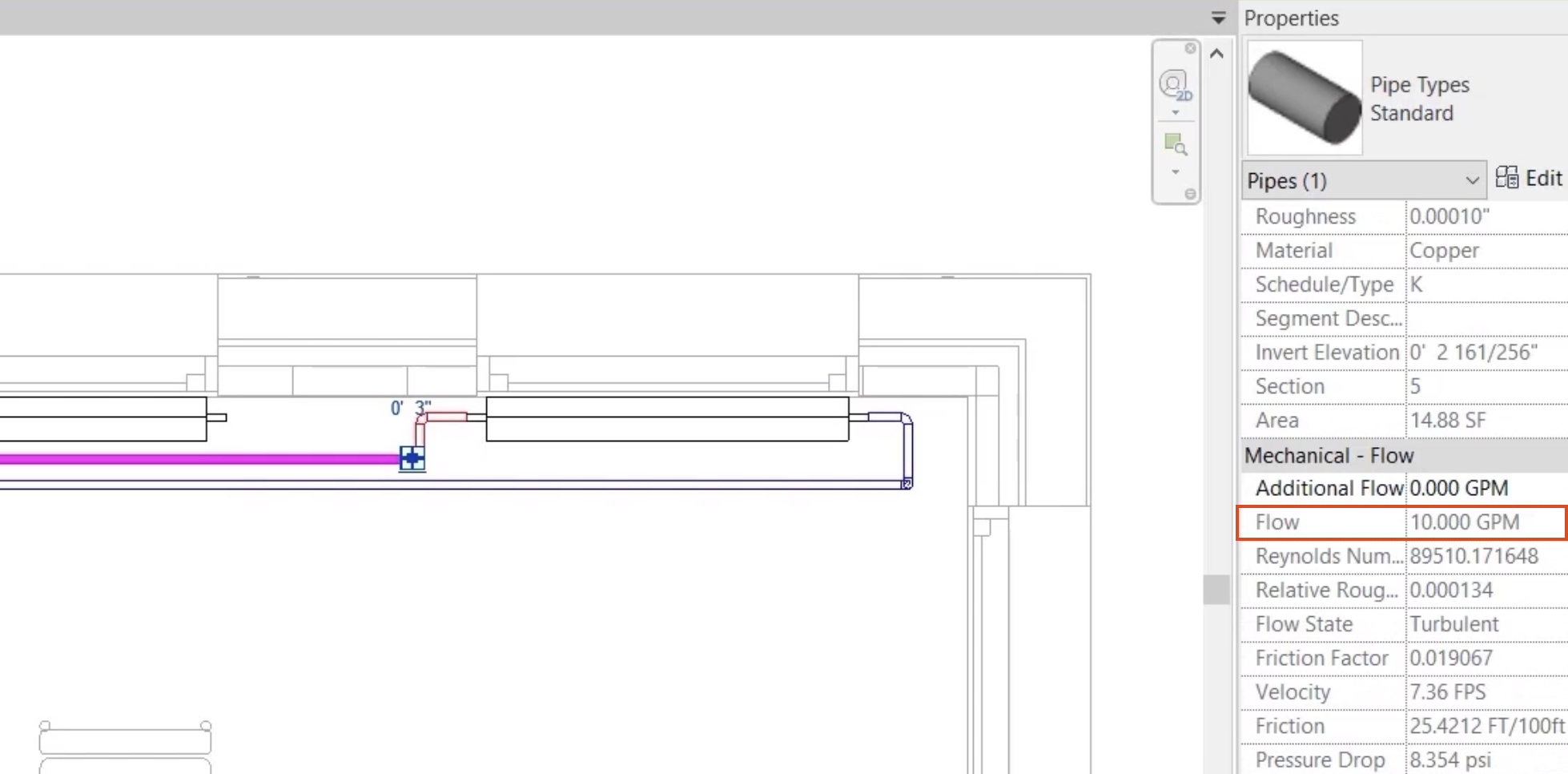

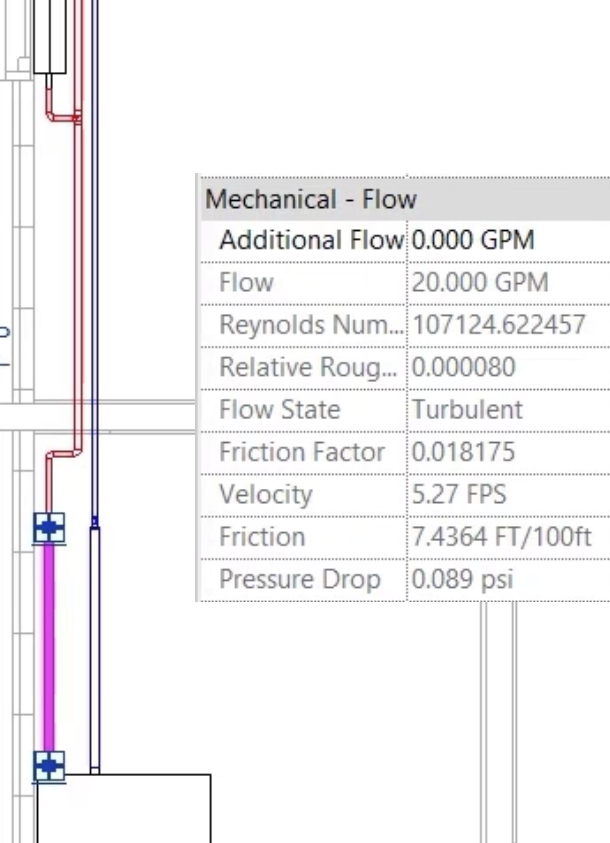

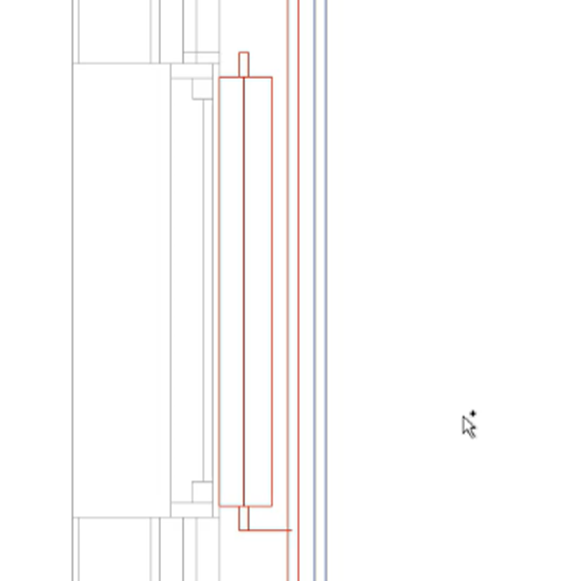

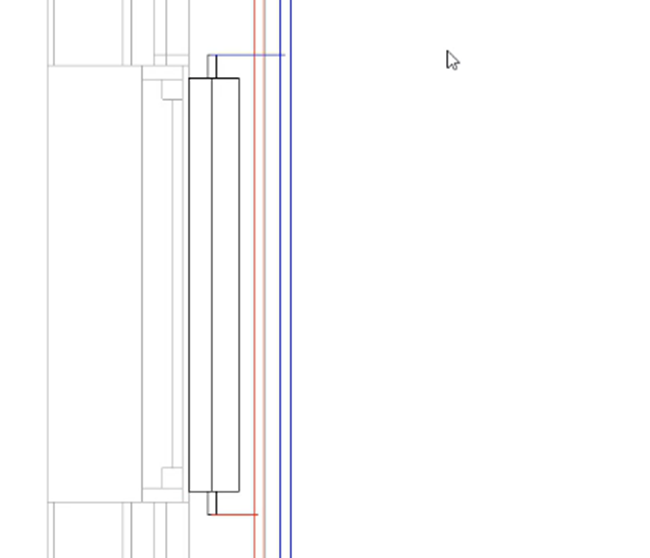

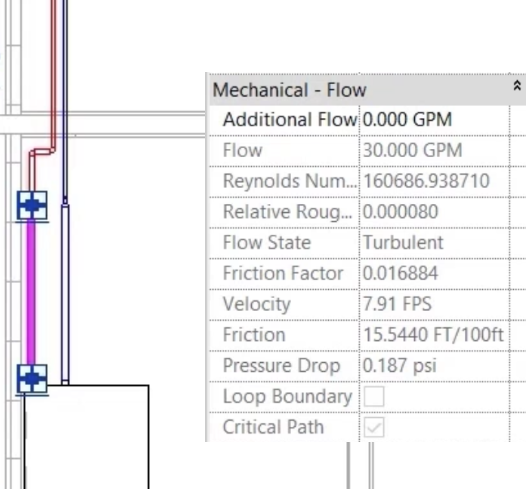

Create a piping system with physical connections and review connection properties.

Tutorial resources

These downloadable resources will be used to complete this tutorial:

Create a piping system with physical connections and review connection properties.

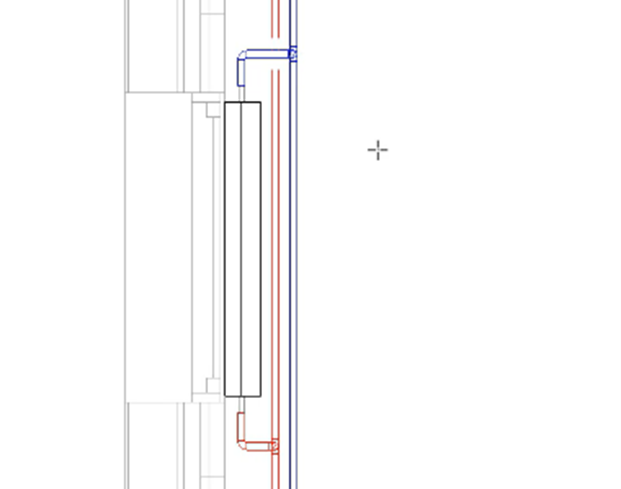

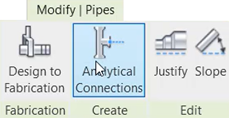

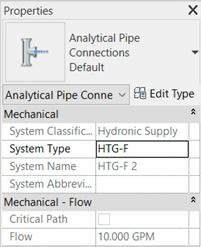

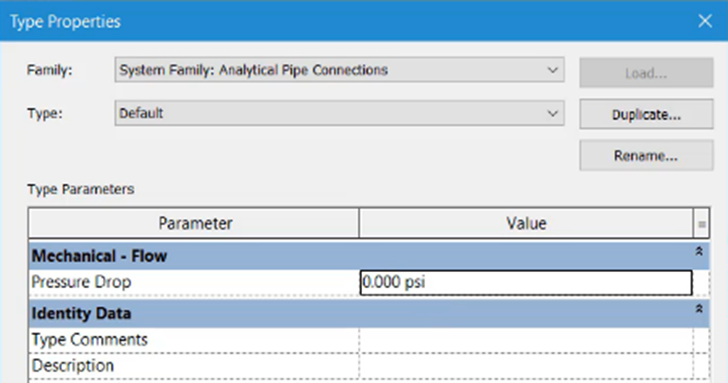

Complete the system using analytical connections: