& Construction

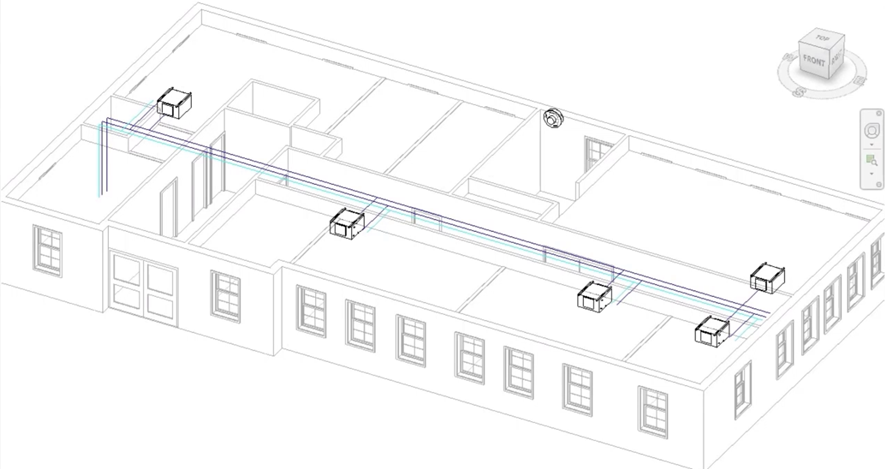

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

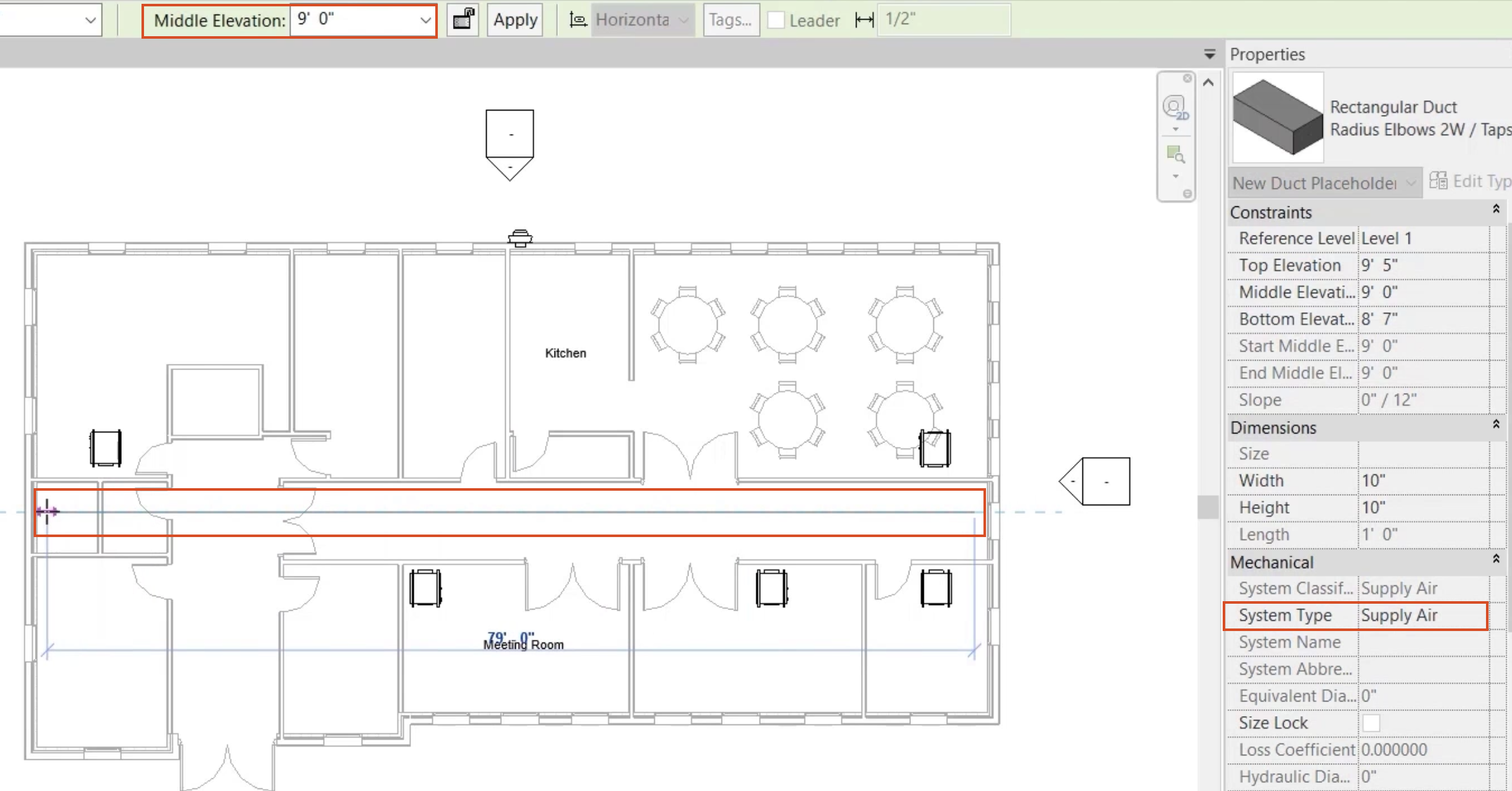

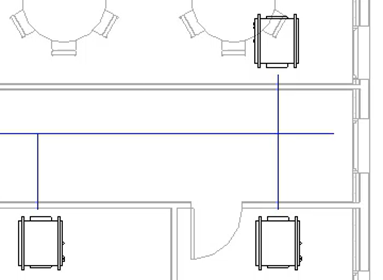

Understand and create conceptual duct and pipe layouts.

Tutorial resources

These downloadable resources will be used to complete this tutorial:

Understand and create conceptual duct and pipe layouts.