& Construction

Integrated BIM tools, including Revit, AutoCAD, and Civil 3D

& Manufacturing

Professional CAD/CAM tools built on Inventor and AutoCAD

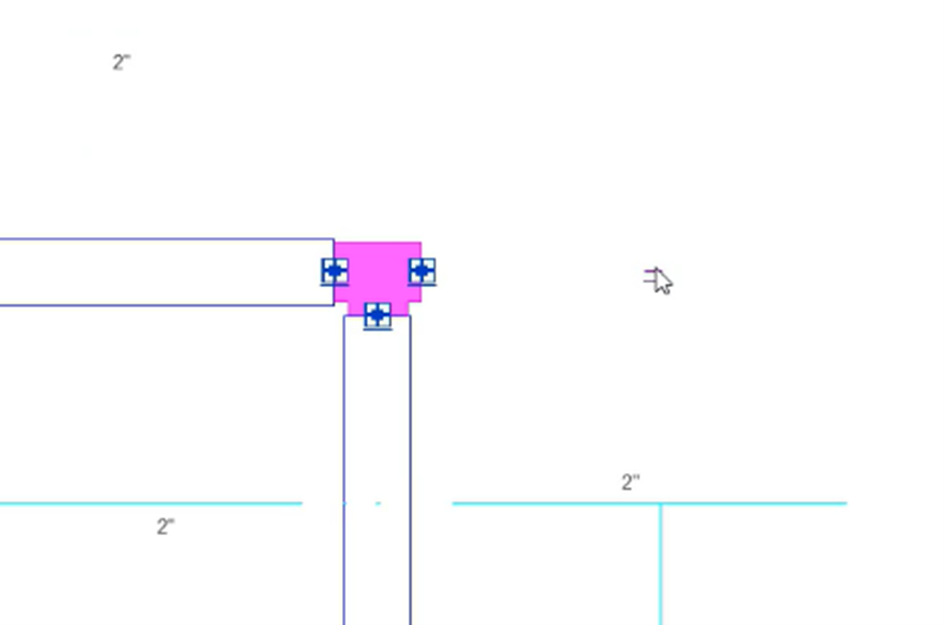

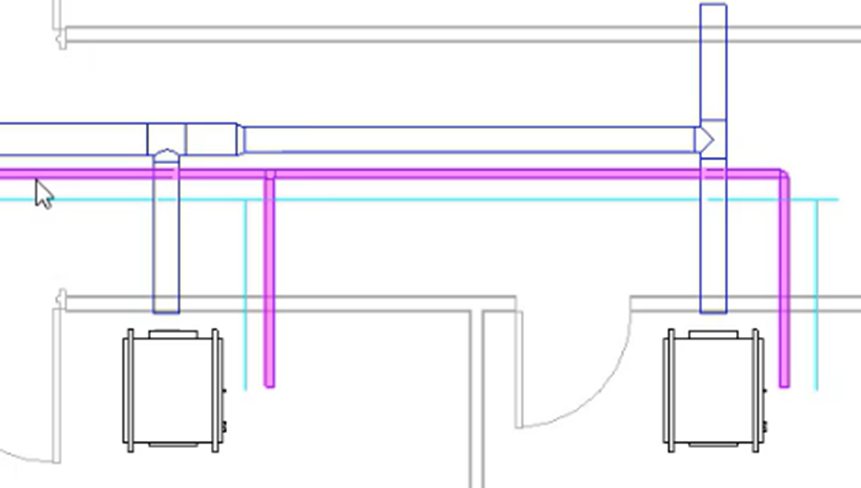

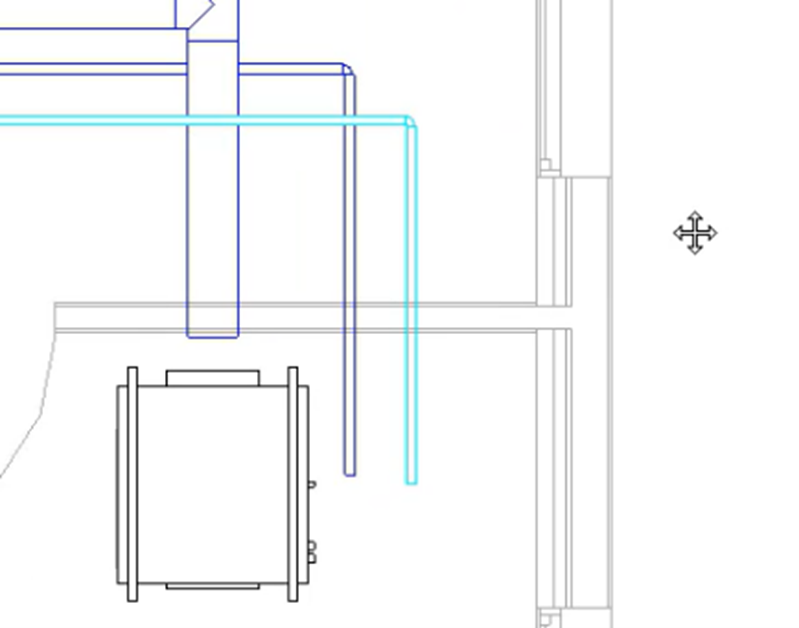

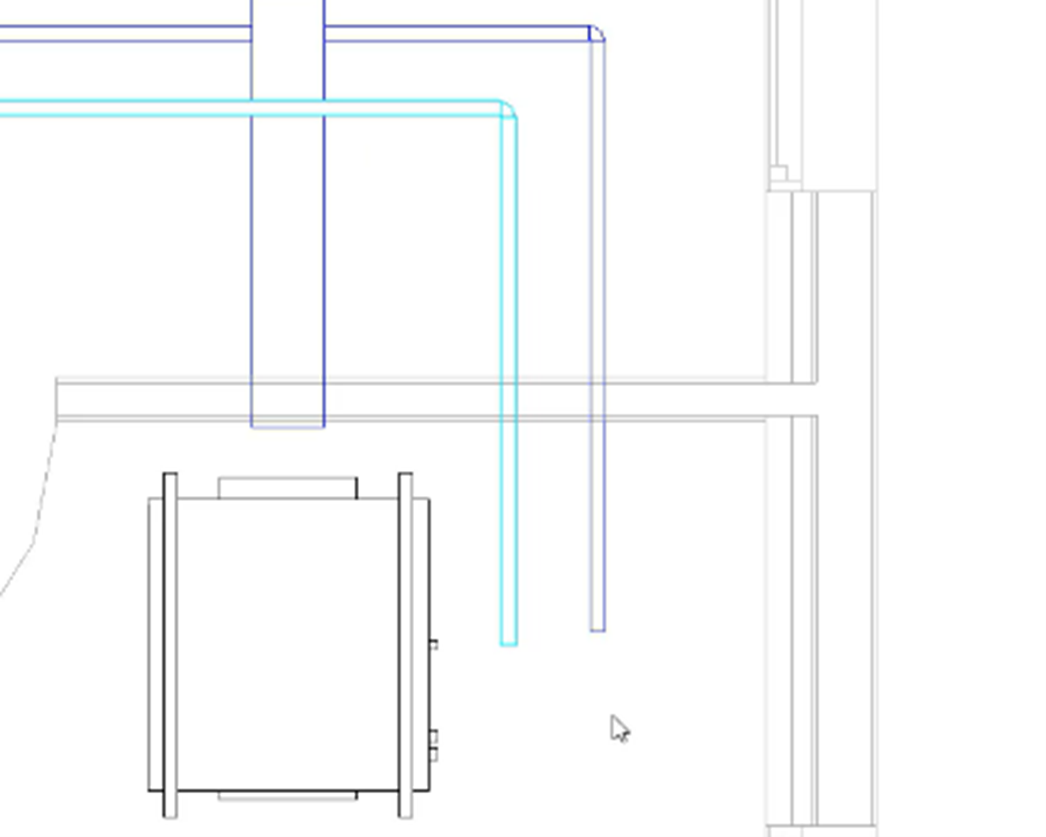

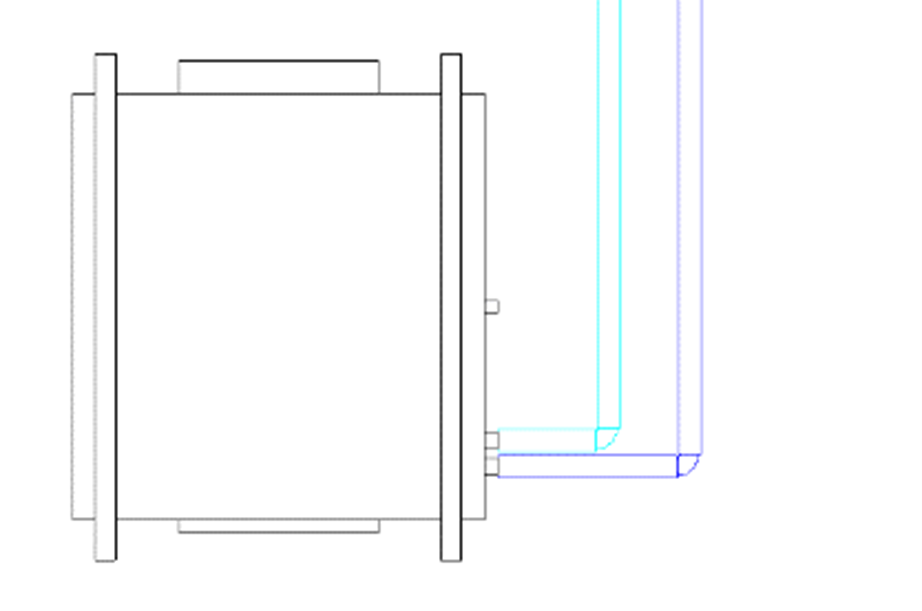

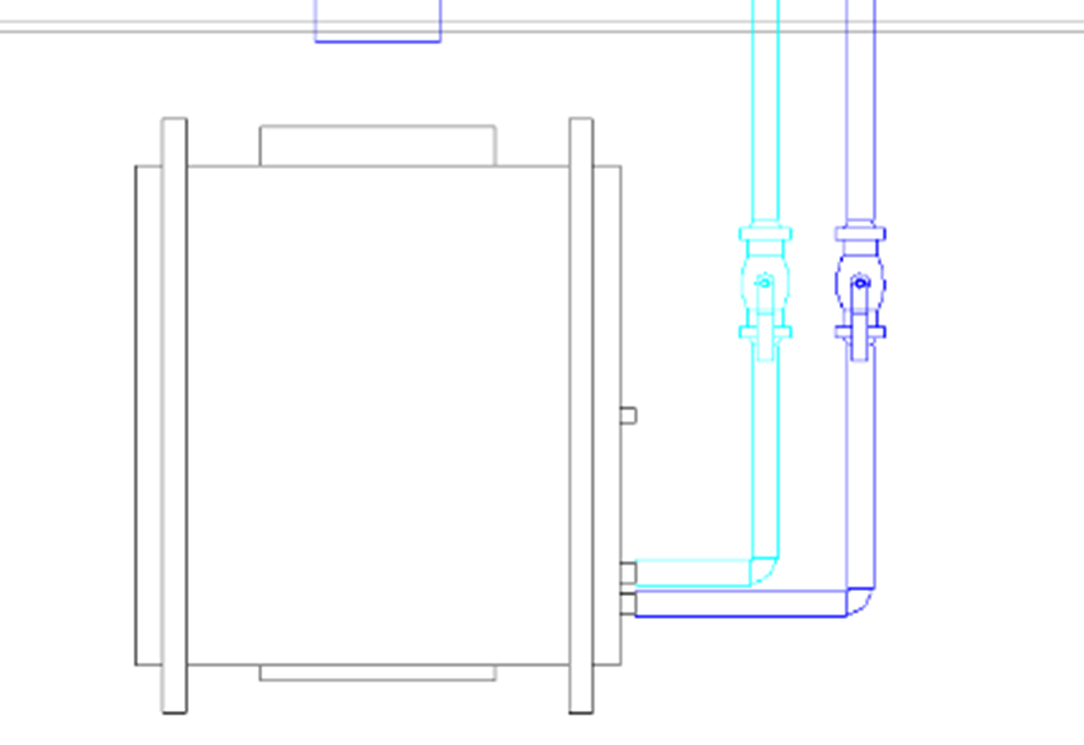

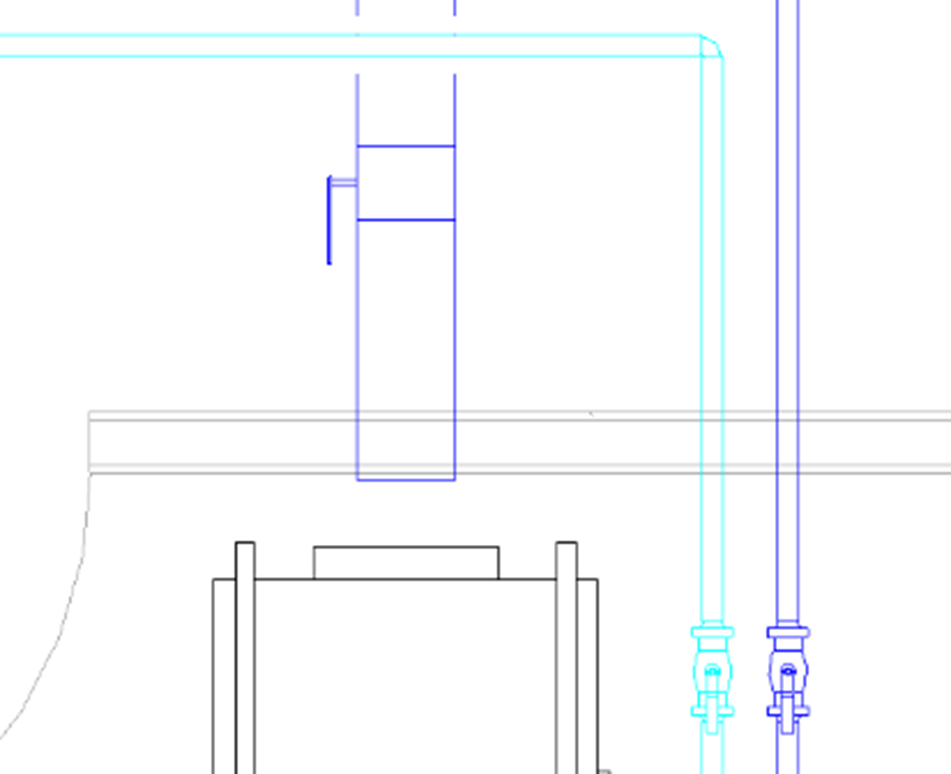

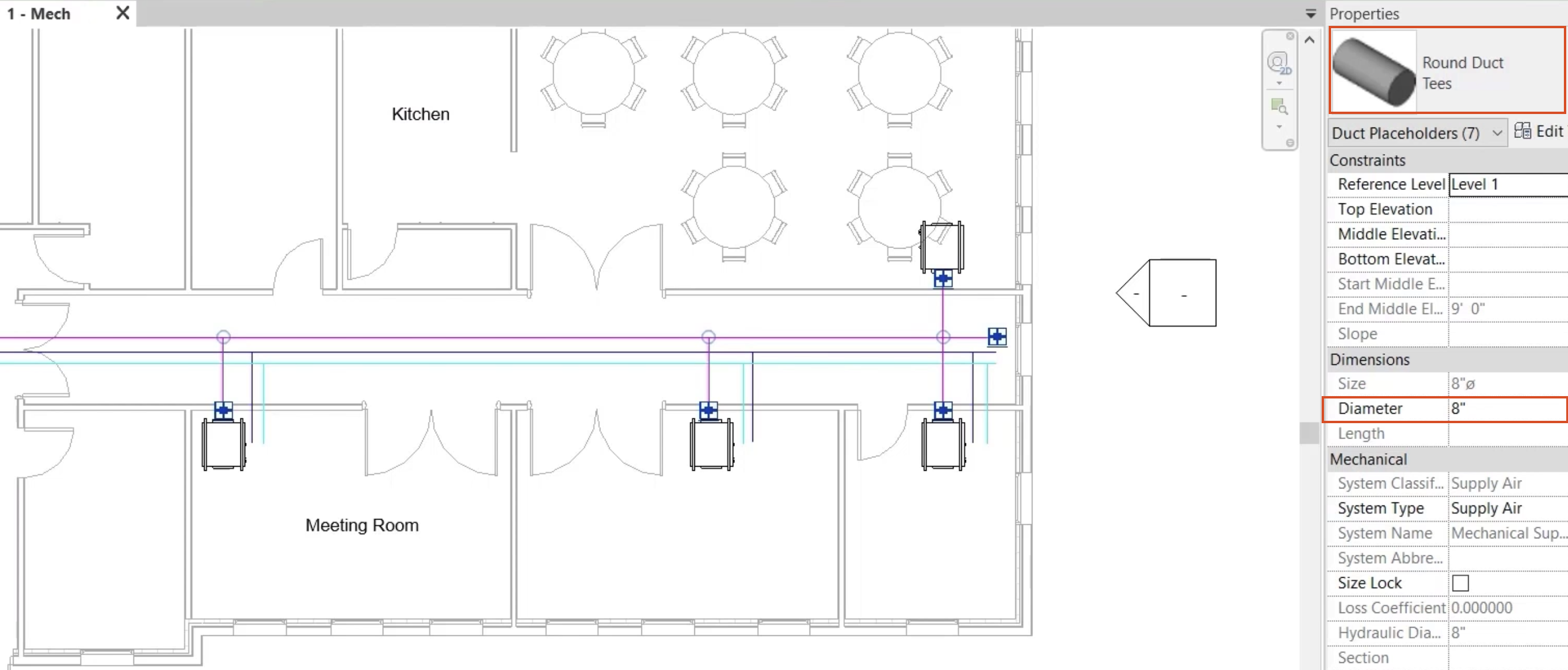

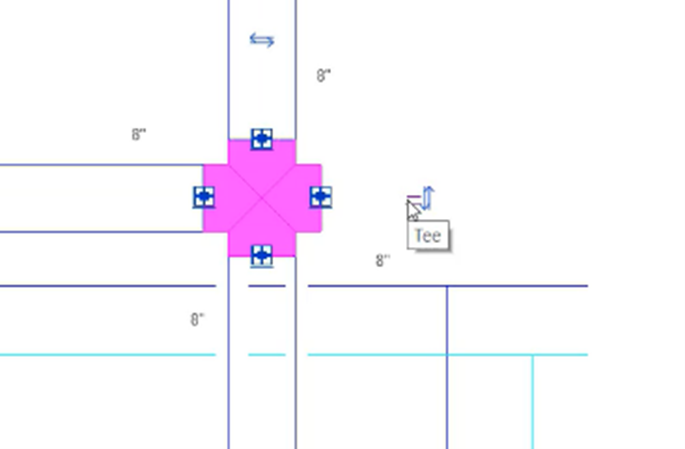

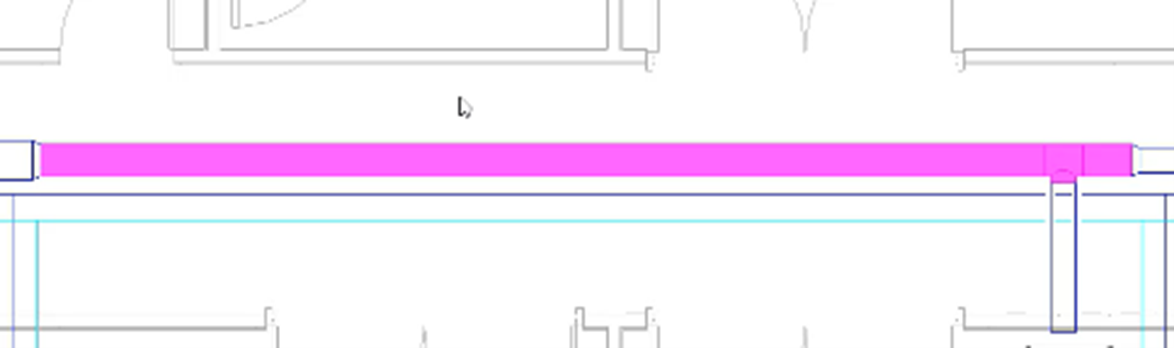

Convert duct and pipe placeholder layouts.

Tutorial resources

These downloadable resources will be used to complete this tutorial:

Convert duct and pipe placeholder layouts.

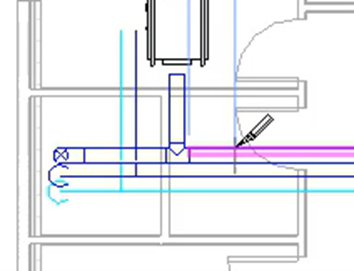

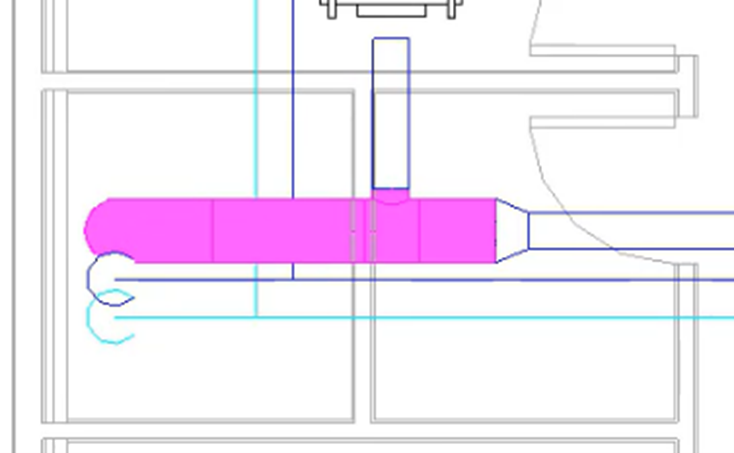

Use the regular editing tools to make the necessary adjustments:

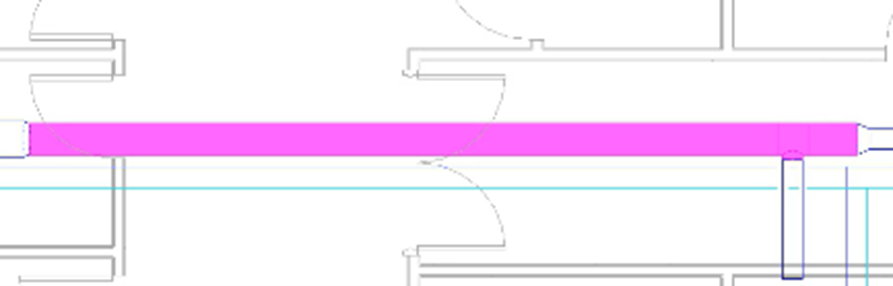

Again, use the regular editing tools to make adjustments: